A low heat leakage flexible cable

A flexible cable, low heat leakage technology, used in insulated cables, bendable cables, cables, etc., can solve the problems of high solid heat leakage and environmental test reliability, improve anti-disturbance ability, reduce solid heat leakage, The effect of reducing input power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

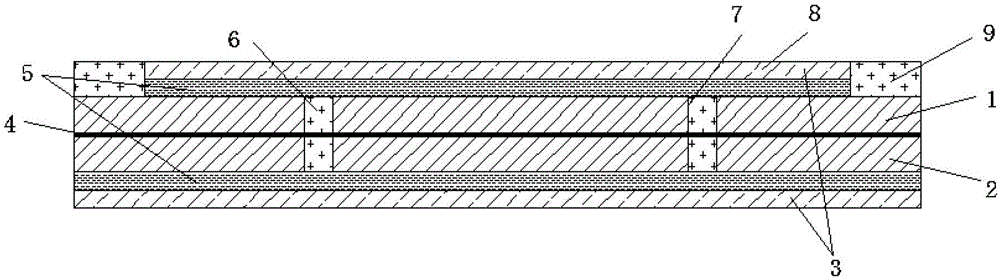

[0028] According to the above realization method, we designed and manufactured a low heat leakage flexible cable with a length of 200mm for the large area array Dewar project. The detector is a 1k×1kHgCdTe infrared shortwave detector. The upper conductive layer of the low heat leakage flexible cable And the lower conductive layer 2 is made of manganese-copper alloy material grade 6J12, the thickness is 35μm, and the length and width are 200×150mm; the coating layer 4 and the bonding layer 8 are made of epoxy adhesive material model JA751; the reinforcing layer 3 is made of polyimide The thickness of the amine material is 0.1mm, and the model is DuPont’s SP-3 film. The via hole 6 adopts a Φ0.2mm hole. There are 90 via holes evenly distributed on a low heat leakage flexible cable, and the metallization layer 7 in the hole is electroplated. Copper, the plating layer is 15 μm, and the gold layer thickness of the electrode gold plating layer 9 is 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com