Optical coupler and manufacturing method thereof

An optical coupler and optical detection technology, which is applied in the coupling of optical waveguides, optical guides, optics, etc., can solve the problems of increased input power consumption of the device, the area of the photodiode should not be too large, and the output current capability of the photodiode is weak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

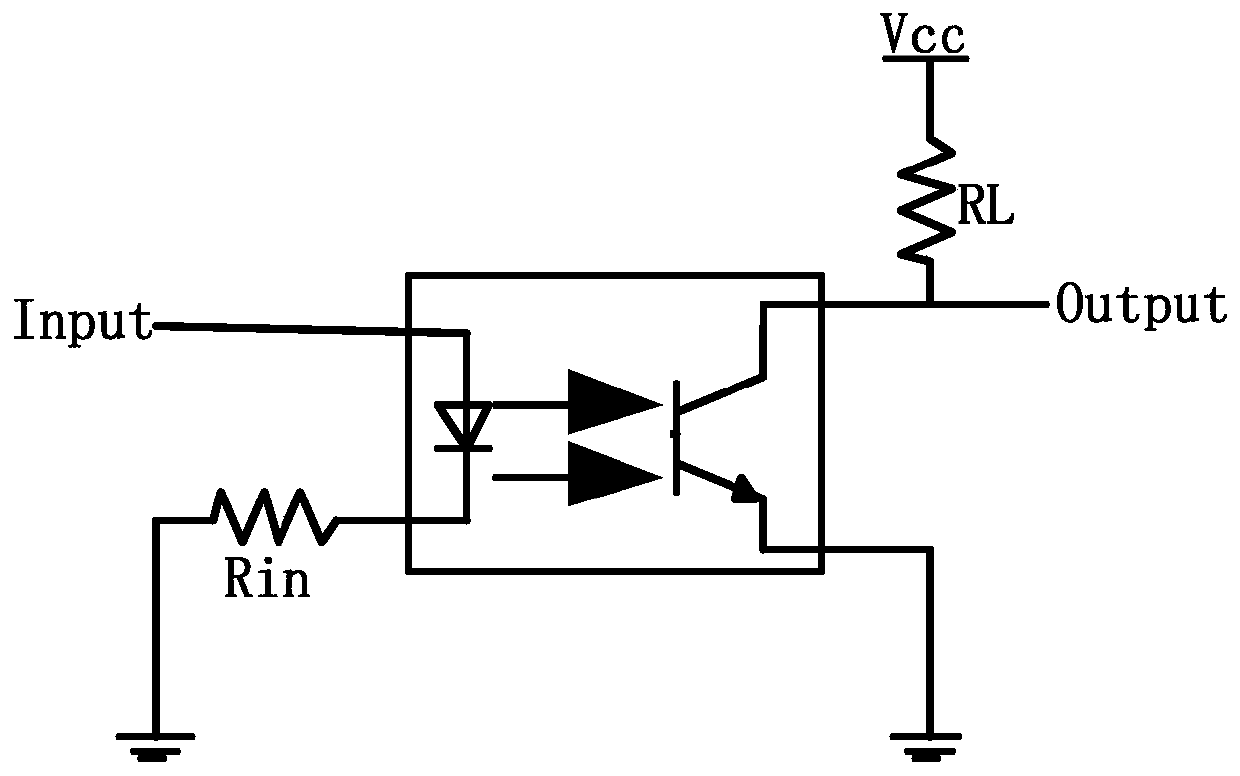

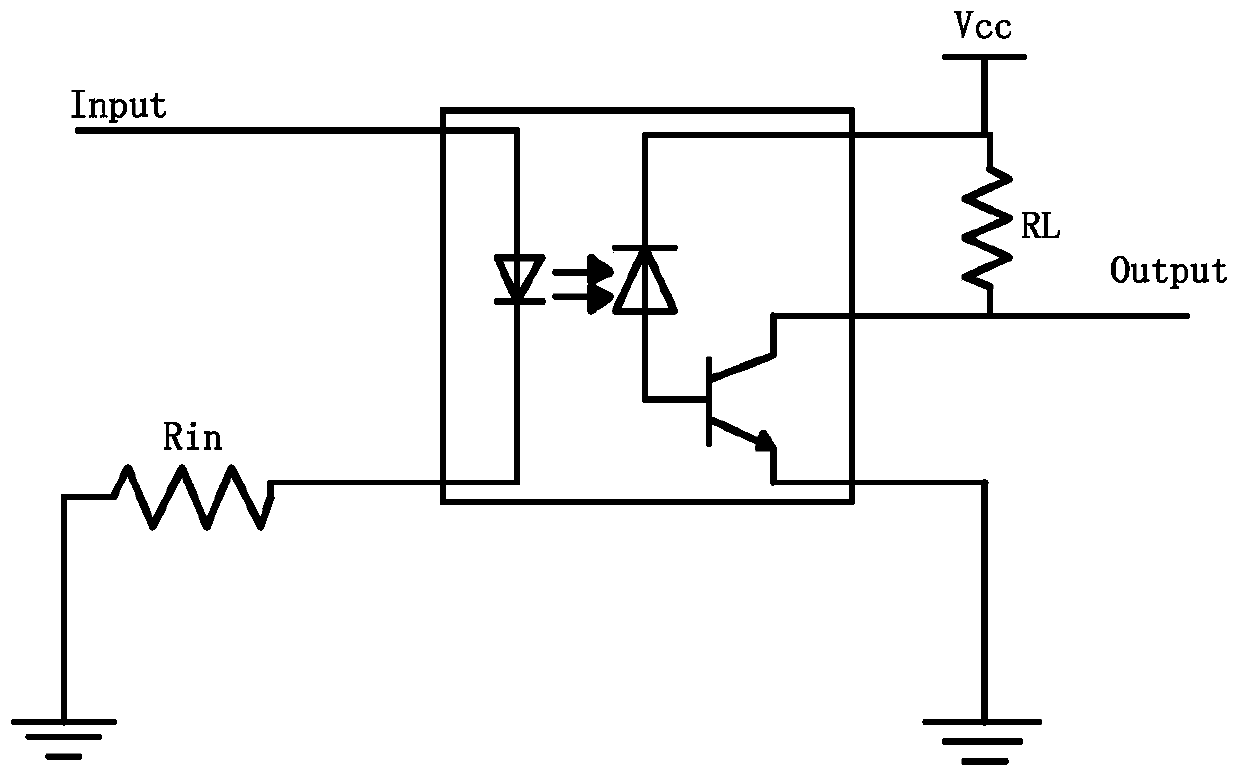

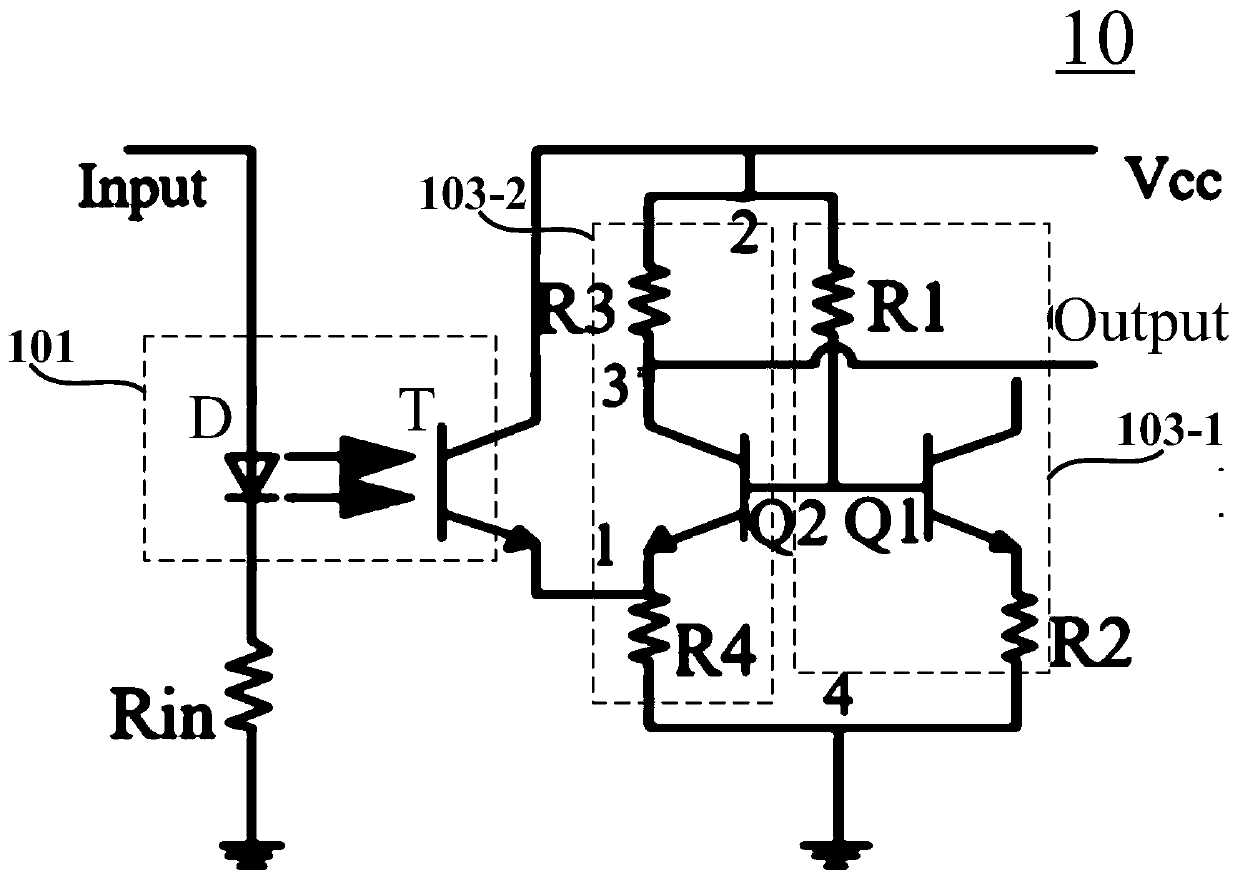

[0025] Combine below image 3 with Figure 4 Describe the structural principle of the optical coupler 10 according to the embodiment of the present application, wherein, image 3 It is a schematic circuit schematic diagram of an optocoupler 10 according to an embodiment of the present application; Figure 4 It is a schematic diagram showing each port of the optical coupler 10 according to the embodiment of the present application.

[0026] combine first image 3 Describe the specific internal structure of the circuit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com