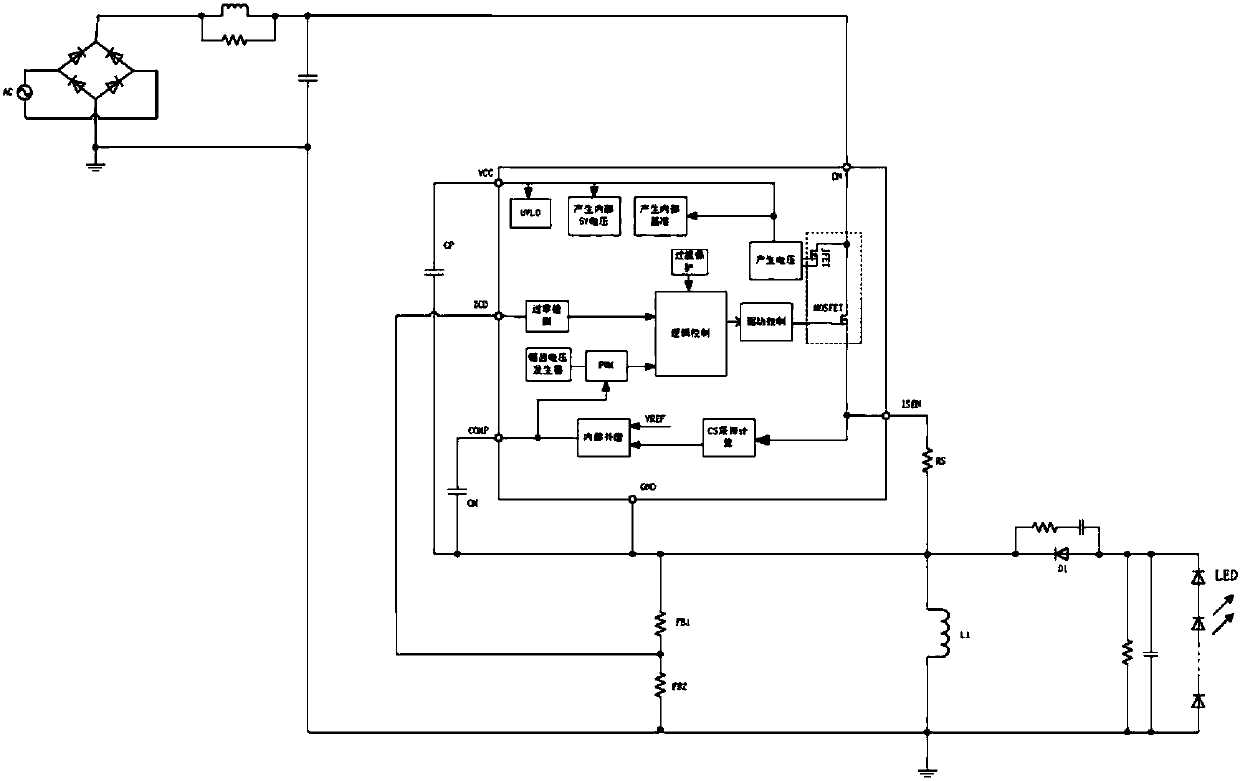

LED short-circuit protection circuit for BUCK-BOOST LED drive circuit

A short-circuit protection circuit and drive circuit technology, which is applied in the direction of electric light sources, electrical components, electroluminescent light sources, etc., can solve the problems of inductive current discharge, circuit failure, high-voltage MOSFET burnout and breakdown, etc., to reduce input power consumption , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] combine Figure 2 to Figure 5 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

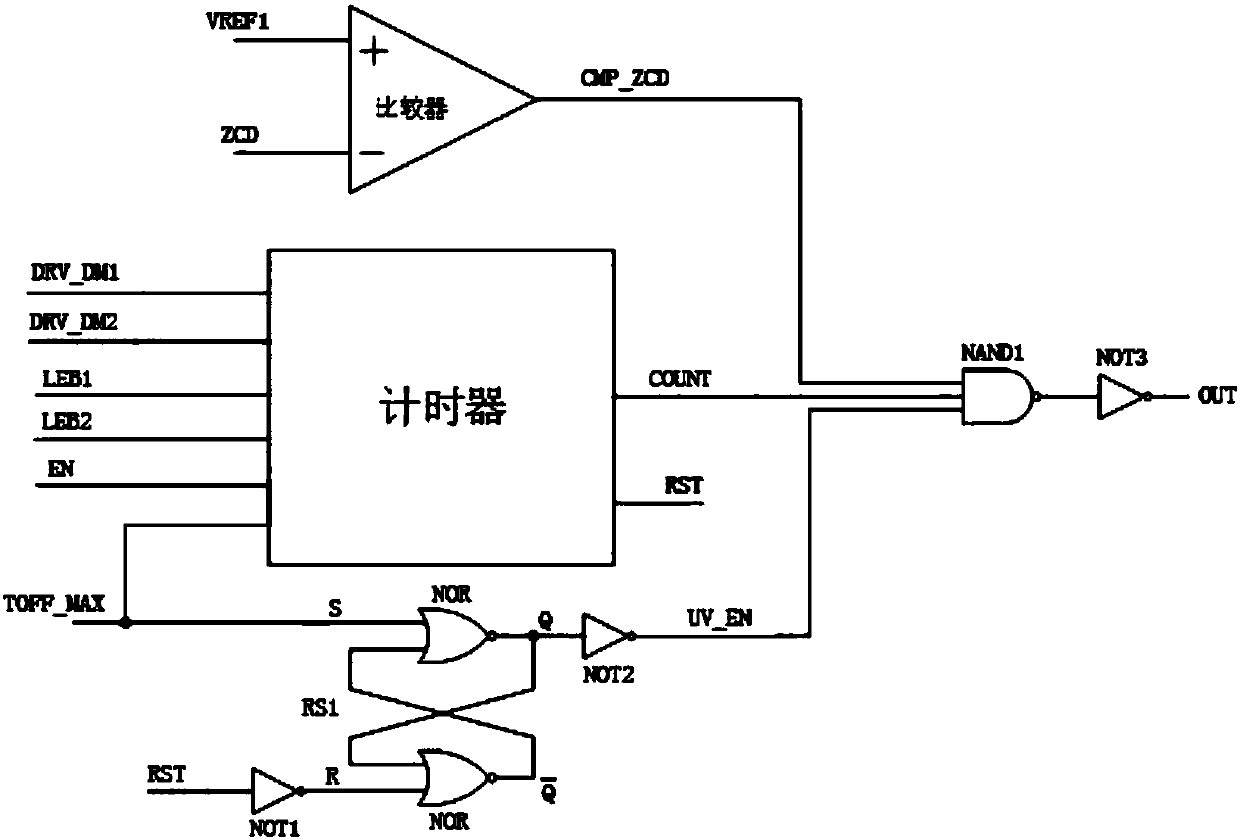

[0045] Such as figure 2 and image 3 As shown, an LED short-circuit protection circuit for BUCK-BOOST LED driving circuit, including a comparator, a timer, a first RS flip-flop RS1, a first NOT gate NOT1, a second NOT gate NOT2, and a third NOT gate NOT3 And the first NAND gate NAND1;

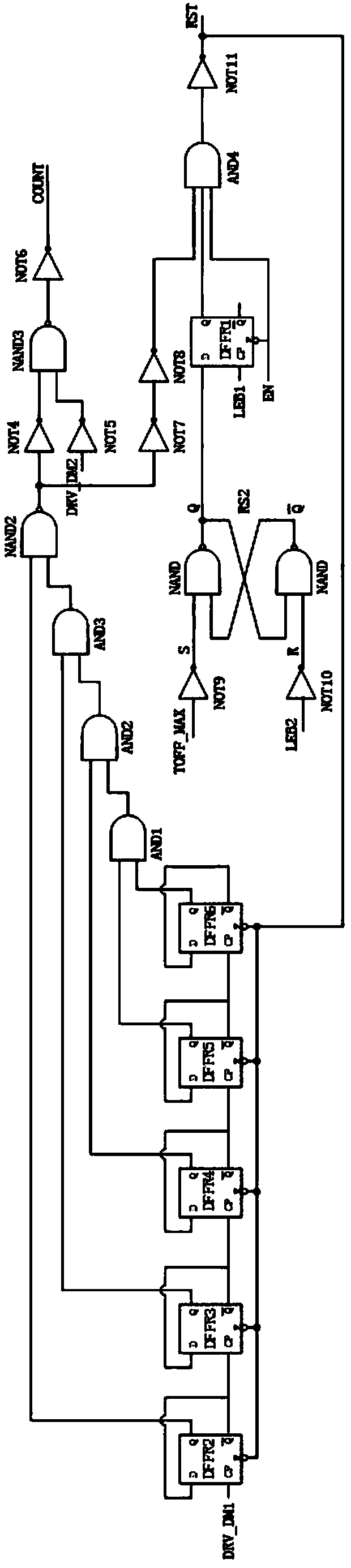

[0046] The first RS flip-flop RS1 is composed of two NOR gates, and the timer includes the first D flip-flop DFFR1, the second D flip-flop DFFR2, the third D flip-flop DFFR3, the fourth D flip-flop DFFR4, the fifth D flip-flop The device DFFR5, the sixth D flip-flop DFFR6, the second RS flip-flop RS2, the first AND gate AND1, the second AND gate AND2, the third AND gate AND3, the fourth AND gate AND4, the second NAND gate NAND2, the third NAND gate NAND3, fourth NOT gate NOT4, fifth NOT gate NOT5, sixth NOT gat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com