Preparation technique for silver powder for preparing printing paste

A preparation process and printing paste technology, applied in the field of electronic paste, can solve the problems of poor conductivity of conductive silver paste, wide distribution range of silver powder particle size, inconsistent morphology, etc., and achieve easy implementation or adjustment and narrow particle size range. , the appearance of the same effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

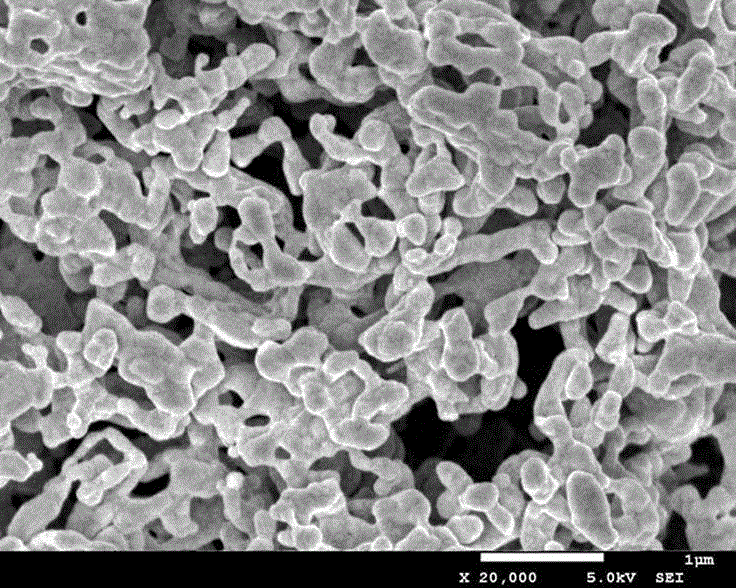

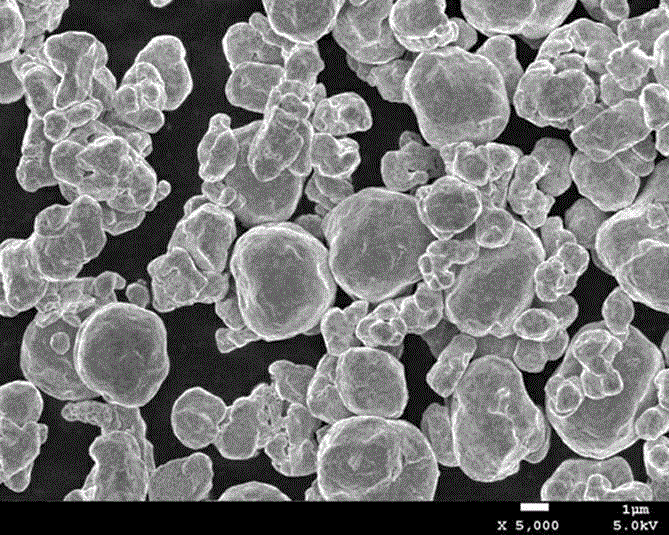

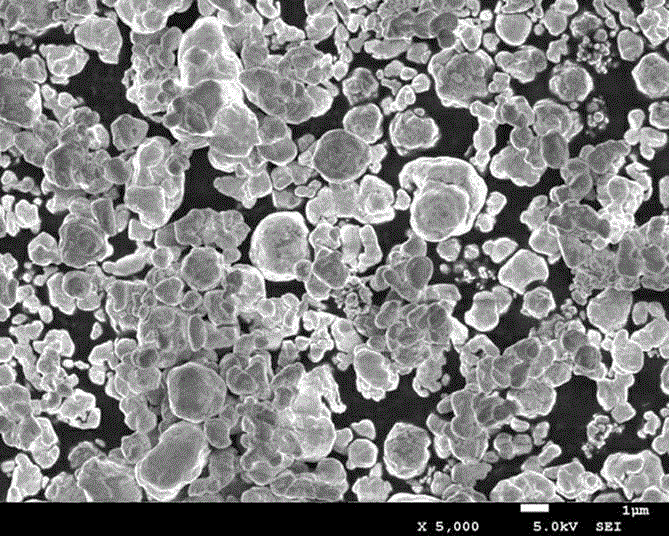

Image

Examples

Embodiment 1

[0037] A kind of preparation technology of silver powder for printing paste in the present embodiment comprises the following steps:

[0038] Step S100: Add 45,000 g of silver nitrate crystals to 300 L of deionized water, and stir continuously until they are all dissolved to obtain a silver nitrate solution;

[0039] Step S200: adding 25200-40000 g of sodium carbonate crystals into 100 L of hot deionized water, stirring continuously and dissolving it to obtain a sodium carbonate solution;

[0040] Step S300: Take the silver nitrate solution and the sodium carbonate solution respectively, add the sodium carbonate solution into the silver nitrate solution at a flow rate of 2500ml / min under stirring, and continue stirring until complete reaction, to obtain Solution A;

[0041] Step S400: Add 30.96L of 16.5% formaldehyde solution to the solution A at a flow rate of 750ml / min until complete reaction, and control the temperature at 30-40°C during the reaction to obtain solution B; ...

Embodiment 2

[0046] This embodiment is further optimized on the basis of Embodiment 1. In the step S200, 40000 g of sodium carbonate crystals are added to 100 L of hot deionized water.

[0047] A kind of preparation technology of silver powder for printing paste in the present embodiment comprises the following steps:

[0048] Step S100: In the first reactor, add 45,000 g of silver nitrate crystals into 300 L of deionized water, and stir continuously until they are all dissolved to obtain a silver nitrate solution;

[0049] Step S200: In the second reaction kettle, add 40,000 g of sodium carbonate crystals into 100 L of hot deionized water, stir and dissolve to obtain a sodium carbonate solution;

[0050] Step S300: Add the sodium carbonate solution into the silver nitrate solution at a flow rate of 2500ml / min under stirring, and continue stirring until the reaction is complete to obtain solution A;

[0051]Step S400: Add 16.5% formaldehyde solution to the solution A at a flow rate of 750...

Embodiment 3

[0055] This embodiment is further optimized on the basis of embodiment 1. In the step S200, 27500 g of sodium carbonate crystals are added to 100 L of hot deionized water.

[0056] A kind of preparation technology of silver powder for printing paste in the present embodiment comprises the following steps:

[0057] Step S100: In the first reactor, add 45,000 g of silver nitrate crystals into 300 L of deionized water, and stir continuously until they are all dissolved to obtain a silver nitrate solution;

[0058] Step S200: In the second reaction kettle, add 27500 g of sodium carbonate crystals into 100 L of hot deionized water, stir and dissolve to obtain a sodium carbonate solution;

[0059] Step S300: Add the sodium carbonate solution to the silver nitrate solution at a flow rate of 2500ml / min under stirring, and continue to stir until the reaction is complete to obtain solution A;

[0060] Step S400: Add 16.5% formaldehyde solution to the solution A at a flow rate of 750ml / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com