Method for synthesizing flower-shaped silver micro-particles

A technology of micron particles and synthesis method, which is applied in the field of morphology control and synthesis of silver particles, can solve problems such as corrosiveness and complicated operation, and achieve the effects of simple operation, good repeatability and controllable morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0028] The synthetic method of the present embodiment flower shape silver microparticles comprises the following steps:

[0029] ① Weigh 1.0004g (0.005680 mol) white solid powder of ascorbic acid (CAS No.: 50-81-7)) into a beaker filled with 10mL of deionized water, stir to dissolve ascorbic acid and set aside, the concentration of ascorbic acid solution is 0.5680 mol / L.

[0030] Weigh 0.9987g of silver nitrate (0.005879mol) crystals and add it to 10mL of deionized water, stir to dissolve the silver nitrate for use, and the concentration of the silver nitrate solution is 0.5879 mol / L.

[0031] The molar ratio of ascorbic acid to silver nitrate is preferably controlled at 0.8-1.2:1, and is 0.97:1 in this embodiment.

[0032] The concentration of the ascorbic acid solution is preferably controlled at 0.5 mol / L-0.7 mol / L; the concentration of the silver nitrate solution is preferably controlled at 0.5 mol / L-0.75 mol / L.

[0033] ② Add the ascorbic acid solution configured in ste...

Embodiment 2)

[0041] The synthetic method of the flower-shaped silver microparticles of the present embodiment is the same as that of Example 1, except that:

[0042] In step ①, add 1.0006g of ascorbic acid to 10ml of deionized water, stir to dissolve the ascorbic acid; add 0.9985g of silver nitrate crystals to 10ml of deionized water, and stir to dissolve the silver nitrate.

[0043] In step ②, add the ascorbic acid solution prepared in step ① into the silver nitrate solution, and immediately add 1.6021 g of cleaned 201 stainless steel sheet to the mixed solution; while the reaction material is magnetically stirred, use a micro pump to feed air into the reaction material , After 240min, the reaction ended. The air flow rate is 8 mL / min.

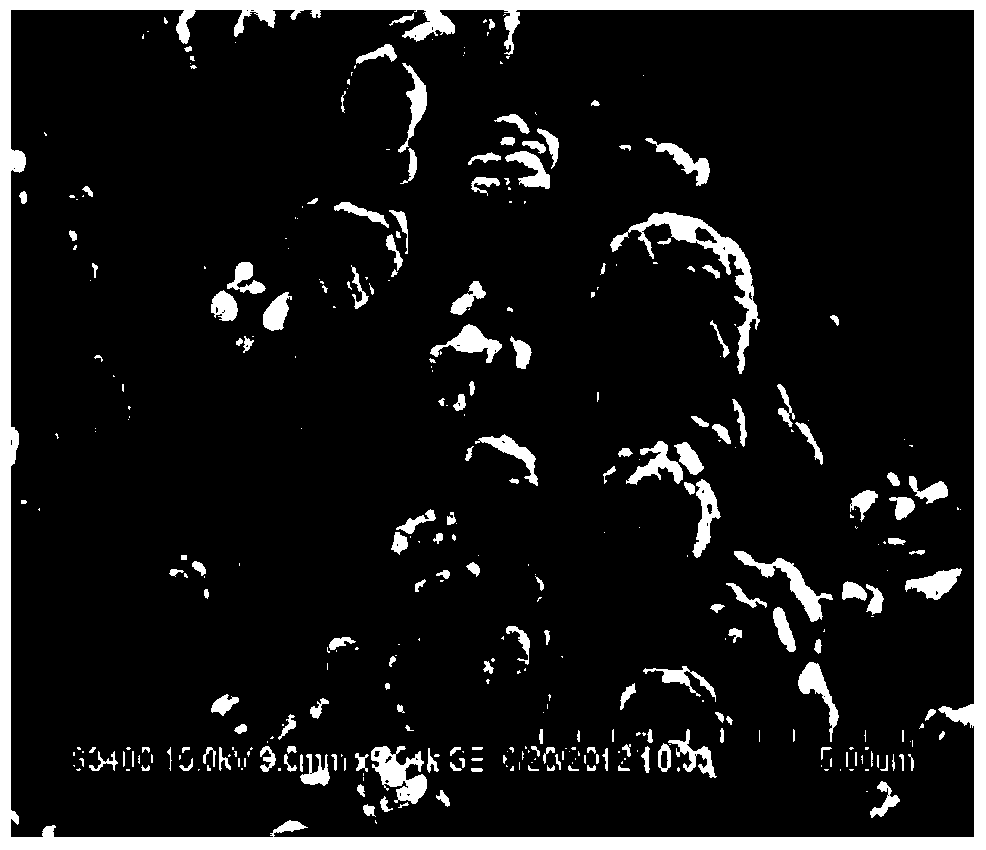

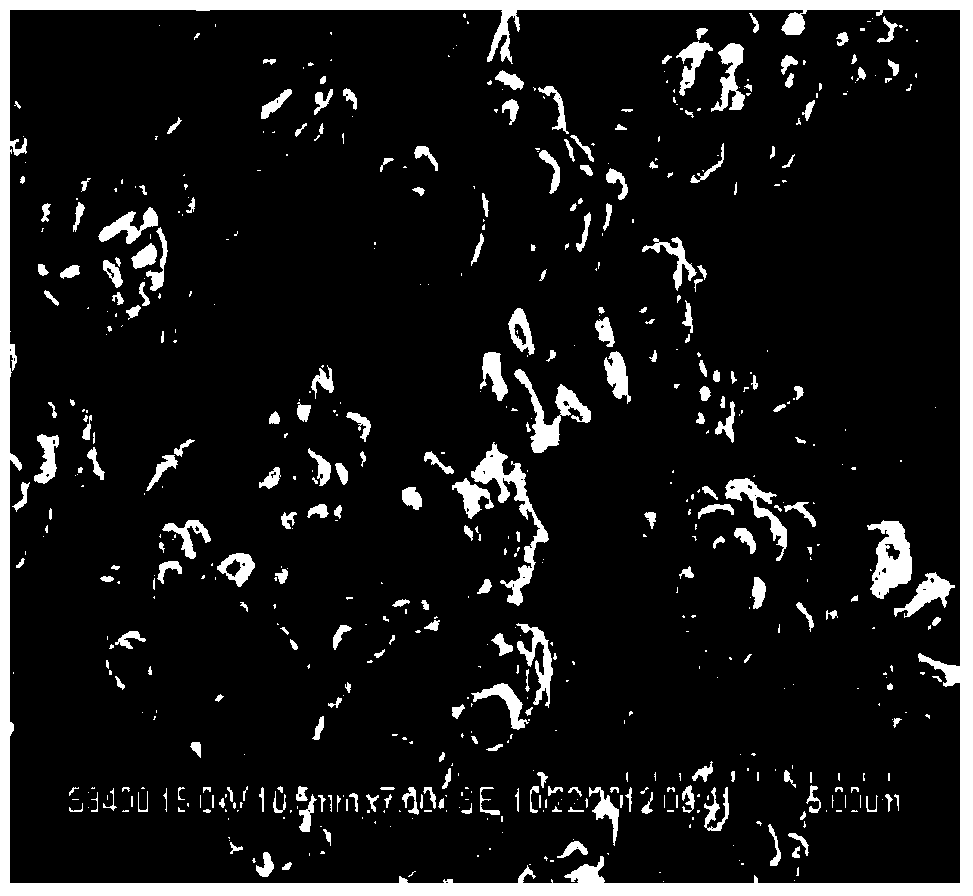

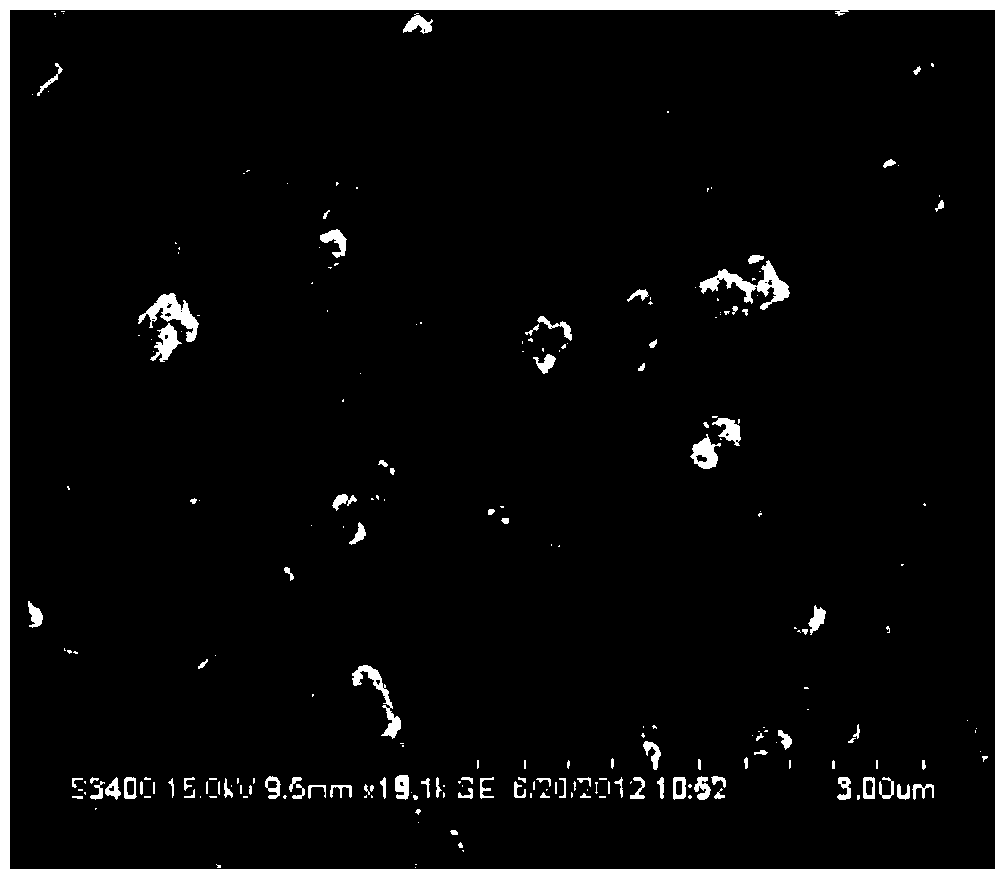

[0044] The SEM results of the product are shown in figure 2 , the product has a relatively uniform morphology and good dispersion. The SEM photo of the powder shows that the particles are rose-shaped, and the particle size of the particles is about 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com