Preparation method of multifunctional ecological ceramic floor tile

An ecological ceramic and multi-functional technology, applied in the field of decorative materials, can solve the problems of ceramic tiles with a single function and products without multiple functions, and achieve the effects of enhanced repulsion, more surface active sites, and strong permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

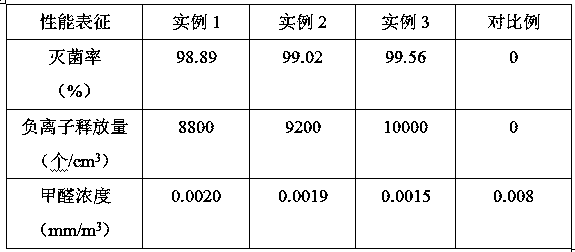

Examples

Embodiment Construction

[0024] Mix silver nitrate crystals and tourmaline powder at a mass ratio of 5:2 to obtain a blend, and place the blend in a ball mill with a mass ratio of steel balls to the blend of 2:1 and a stirring speed of 400 to 460r Ball milling at 3-5min per minute to obtain the mixture. Add 0.2mol / L sodium borohydride solution to the mixture at a mass ratio of 3:1, and continue ball-milling for 1-2 hours to obtain the product. Use deionized water and absolute ethanol Wash the products separately and filter them for 2-3 times, then air-dry them naturally at room temperature to obtain the composite product; mix carbon powder and starch at a mass ratio of 1:1, and stir evenly at a stirring speed of 400-500r / min to obtain the hair product. foaming agent; in parts by weight, respectively weigh 30-40 parts of electrolytic manganese slag, 20-30 parts of waste ceramic powder, 10-20 parts of high-alumina mud, 5-15 parts of black talc, 1-10 parts of composite product, 1-3 parts of foaming agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com