A large-scale atmospheric pressure preparation and separation method of silver nanowires

A silver nanowire, large-scale technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as limiting production capacity, agglomeration of nanomaterials, etc., to avoid damage, reduce costs, avoid The effect of preprocessing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

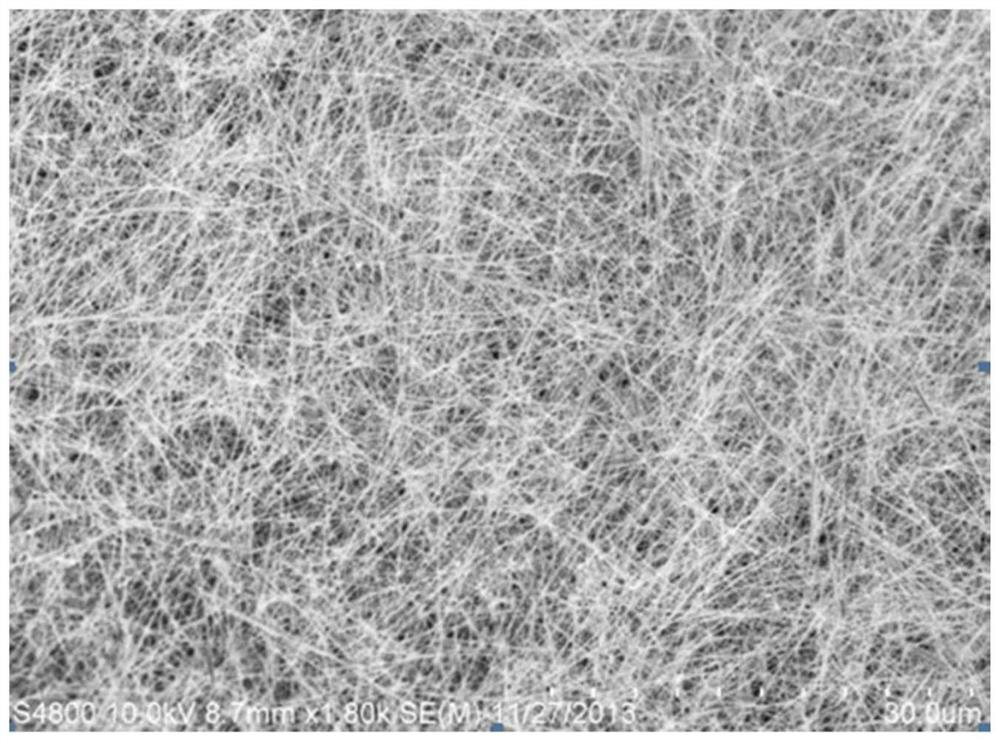

[0033] A method for preparing and separating silver nanowires under normal pressure on a large scale, comprising the following steps:

[0034] Step 1: Add 0.0963g of ammonium chloride to 1,000ml of 1,2-propanediol, heat to 80°C and stir for 1 hour to dissolve, then cool to obtain an ammonium chloride / 1,2-propanediol solution for use. Mix 3,000ml of propylene glycol, 68g of PVP, 800ml of Add the ammonium chloride / 1,2-propanediol solution into a 50L glass reactor with a reflux condensing device, stir and raise the temperature to 160°C to obtain the first mixture;

[0035] Step 2, in a quartz glass grinder, add 54g of silver nitrate crystals to 70ml of 1,2-propanediol for rapid grinding, and when no silver nitrate crystals are observed in the grinder, quickly transfer the silver nitrate suspension to the high position of the reaction kettle tank and ready to be added dropwise to the first mixture in the reactor, the first drop rate is 1 drop / second, when the suspension in the rea...

Embodiment 2

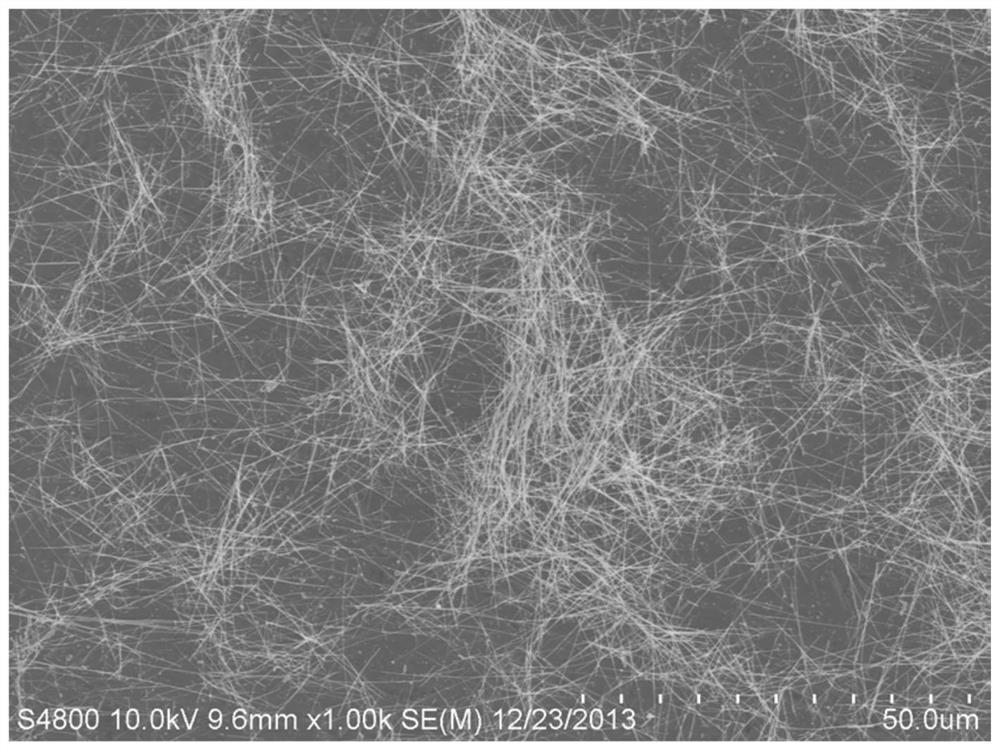

[0038] Step 1: Add 0.12 g of ammonium chloride to 1.2 kg of 1,2-propanediol, heat to 100°C and stir for 20 minutes to dissolve, then cool to obtain an ammonium chloride / 1,2-propanediol solution for use;

[0039] Add 5.5 kg of propylene glycol, 80 g of PVP, and 1.2 kg of ammonium chloride / 1,2-propylene glycol solution into a 50 L glass reactor with a reflux condensing device, stir and raise the temperature to 140°C to obtain the first mixture;

[0040] Step 2, in a quartz glass grinder, add 82g of silver nitrate to 0.09 kg of 1,2-propanediol for rapid grinding, and when no silver nitrate crystals are observed in the grinder, quickly transfer the suspension of silver nitrate to the high position of the reaction kettle tank and ready to be added dropwise to the first mixture in the reactor, the first drop rate is 1 drop / second, when the suspension in the reactor gradually turns dark brown, and gradually becomes black and opaque as the crystal seeds increase, the crystal Seed grow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com