Forging processing method for TC32 titanium alloy large specific bar

A TC32 and processing method technology, applied in the field of titanium alloys, can solve the problems of small structures, inability to obtain comprehensive mechanical properties of products, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

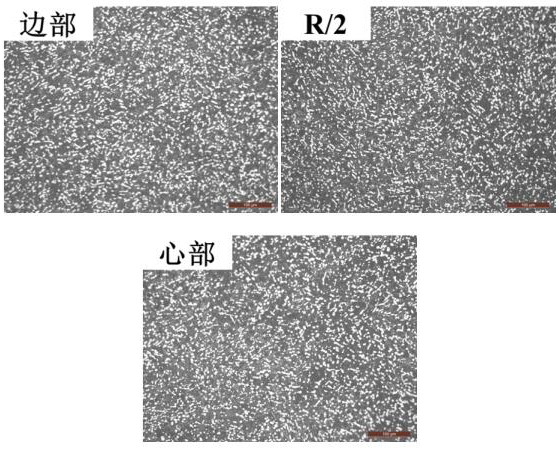

[0035] Example 1 (Forging method of Φ210mm bar material)

[0036] The TC32 titanium alloy Φ780mm ingot is selected, and the β transformation temperature of the ingot is 905°C. The specific forging process is as follows:

[0037] (1) Blank forging

[0038] It is completed in 2 fires. The 1st fire heats the TC32 ingot to 1150°C and keeps it warm. After it is taken out of the furnace, it is subjected to two upsetting and two drawing to a square. The forging ratio is controlled at 9-10, and the height-to-diameter ratio of the billet is controlled at about 2.0. Air cooling is used after forging; The second fire is heated and kept at 1080°C, two upsetting and two drawing are forged to all directions, the forging ratio is controlled at 9-10, and the height-diameter ratio of the billet is finally controlled to be 1.5, and air cooling is used after forging;

[0039] (2) Homogenized forging

[0040] First, heat the billet in step (1) to 870°C and keep it warm. After it comes out of t...

Embodiment 2

[0046] Embodiment 2 (Forging method of Φ380mm bar material)

[0047] The TC32 titanium alloy Φ780mm ingot is selected, and the β transformation temperature of the ingot is 905°C. The specific forging process is as follows:

[0048] (1) Blank forging

[0049] Heat the TC32 ingot to 1150°C and keep it warm, take it out of the furnace and carry out two upsetting and two drawing to Bafang. The diameter ratio is 1.5, and air cooling is adopted after forging;

[0050] (2) Homogenized forging

[0051] First, heat the billet in step (1) to 875°C and keep it warm. After it comes out of the furnace, it is forged to eight directions with one upsetting and one drawing. The forging ratio is controlled at 1.6. The height-to-diameter ratio of the billet after forging is controlled at 1.5. , the time of returning to the furnace and transferring the material is not more than 120s, and the holding time is controlled at 330-360min. After being out of the furnace, forging is carried out with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com