Waterborne photo-curing resin and application thereof

A technology of photocurable resin and photocurable prepolymer, which is applied in the direction of coating, etc., can solve the problems of difficult to effectively use traditional photocurable resin production equipment and raw materials, poor batch stability, etc., and achieve excellent emulsification performance and high hardness , The effect of product batch stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

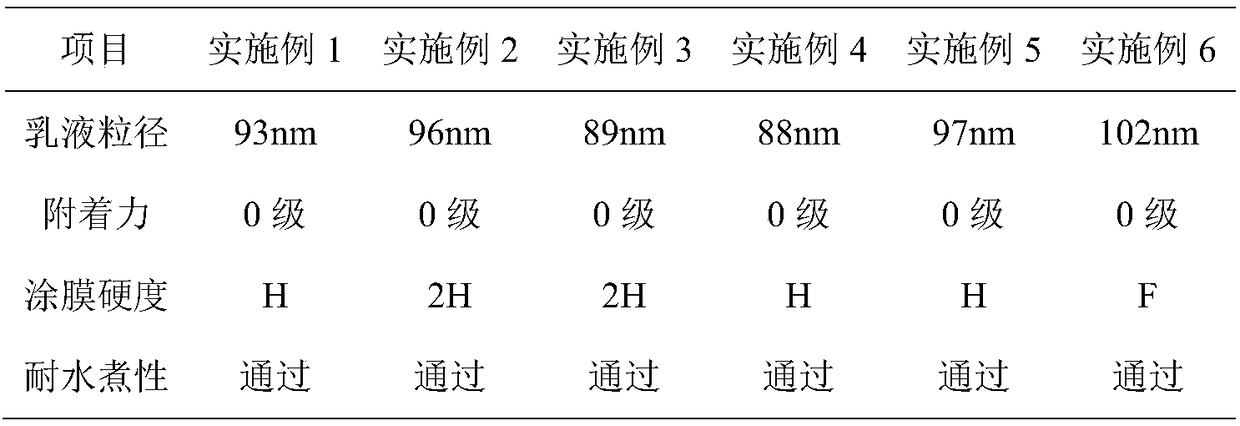

Examples

Embodiment 1

[0043] A water-based photocurable resin is prepared by the following method:

[0044] 1) Add 10 parts of dipropylene glycol methyl ether, 5 parts of propylene glycol methyl ether and 12 parts of Joncyl678 (BASF company) into the reaction vessel and stir to heat up to 100°C; then add 100 parts of styrene, 10 parts of hydroxyethyl methacrylate , 10 parts of acrylic acid, 50 parts of butyl acrylate, 1 part of azobisisobutyronitrile, and 0.02 parts of tert-butyl disulfide were mixed evenly, and added dropwise for 6 hours with a dropping funnel. Acrylate prepolymer.

[0045] 2) Add 10 parts of acrylic acid isocyanate and 0.1 part of hydroquinone to the polyacrylate prepolymer obtained in step 1), and further react at 80° C. for 3 hours to obtain a polyacrylate prepolymer containing carbon-carbon double bonds.

[0046] 3) Add 20 parts of 6145-100 (Changxing Chemical) and 20 parts of EM221 (Changxing Chemical) to the polyacrylate prepolymer containing carbon-carbon double bonds obta...

Embodiment 2

[0048] A water-based photocurable resin is prepared by the following method:

[0049] 1) Add 5 parts of propylene glycol butyl ether and 5 parts of propylene glycol methyl ether into the reaction vessel and stir to raise the temperature to 100°C; then add 100 parts of methyl methacrylate, 10 parts of hydroxyethyl methacrylate, 20 parts of acrylic acid and 50 parts Mix isooctyl acrylate, 1 part of benzoyl peroxide, and 0.02 part of dodecyl mercaptan evenly, add dropwise for 6 hours with a dropping funnel, and keep warm for 2 hours after the dropping to obtain a polyacrylate prepolymer.

[0050] 2) Add 10 parts of glycidyl methacrylate and 0.1 part of p-methoxyphenol to the polyacrylate prepolymer obtained in step 1), and further react at 100°C for 3 hours to obtain polyacrylic acid containing carbon-carbon double bonds ester prepolymer.

[0051] 3) Add 25 parts of 6144-100 (Changxing Chemical) and 15 parts of EM222 (Changxing Chemical) to the polyacrylate prepolymer containing...

Embodiment 3

[0053] A water-based photocurable resin is prepared by the following method:

[0054] 1) Add 10 parts of dipropylene glycol methyl ether, 10 parts of 100# solvent oil and 20 parts of Joncyl678 (BASF company) into the reaction vessel and stir the temperature to 100 °C; then add 100 parts of benzyl methacrylate, 10 parts of acrylate hydroxyl Ethyl ester, 10 parts of acrylic acid, 50 parts of isooctyl methacrylate, 1 part of azobisisoheptanonitrile, and 0.02 part of n-butanethiol were mixed evenly, and added dropwise for 5 hours with a dropping funnel. After the addition, keep warm for 3 hours; A polyacrylate prepolymer is obtained.

[0055] 2) Add 10 parts of acryloyl chloride and 0.1 part of p-hydroxyphenethyl ether to the polyacrylate prepolymer obtained in step 1), and further react at 60° C. for 3 hours to obtain a polyacrylate prepolymer containing carbon-carbon double bonds.

[0056] 3) Add 40 parts of 621A-80 (Changxing Chemical) and 10 parts of EM223 (Changxing Chemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com