Packaging flexible substrate and packaging body

A flexible substrate and substrate technology, which is used in identification devices, electric solid devices, semiconductor devices, etc., can solve the problems of separation of wires and substrates affecting packaging performance and reliability, and achieves advantages such as promotion and application, simple structure, and manufacturing process. mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

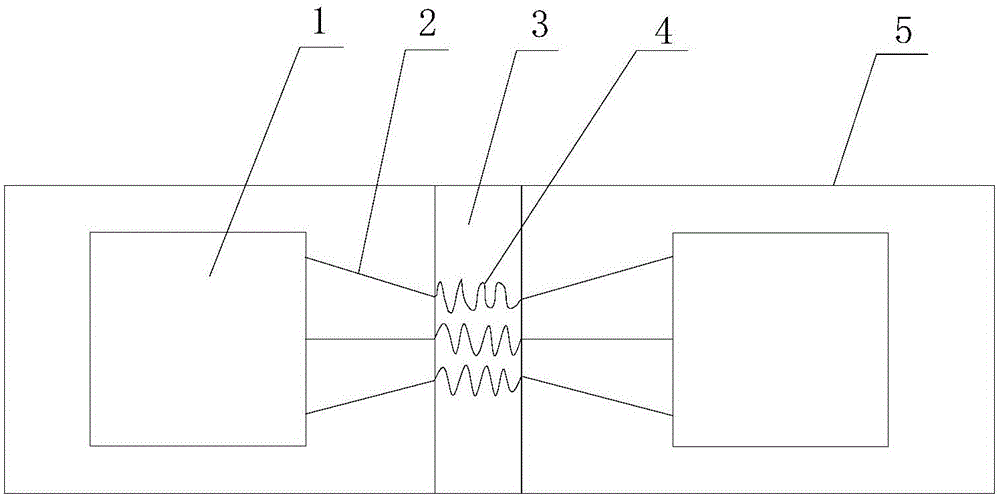

[0032] Such as figure 1 As shown, this embodiment provides a flexible substrate for packaging, wherein a bending area 3 is provided in the middle of the flexible substrate 5, and chips 1 are provided on both sides of the bending area 3 and at both ends of the flexible substrate 5. . The wires 2 passing through the bending area 3 are connected between the two chips 1, and the wires 2 can include all the wires in the bending area 3 of the flexible substrate (that is, the wires on the inner surface of the bend, the wires on the outer surface of the bend, and the bends on the flexible substrate. In addition, a section of the wire 2 corresponding to the bending area 3 is provided with an anti-stress structure 4, that is to say, the part of the wire 2 located in the bending area 3 is provided with an anti-stress structure 4. The anti-stress structure 4 is used to release the tensile and compressive stress when the bending area 3 is bent, so as to improve the reliability of the wire...

Embodiment 2

[0037] The technical content of the second embodiment that is the same as that of the first embodiment will not be described repeatedly. The content disclosed in the first embodiment also belongs to the content disclosed in the second embodiment. The second embodiment is obtained by further modification on the basis of the first embodiment.

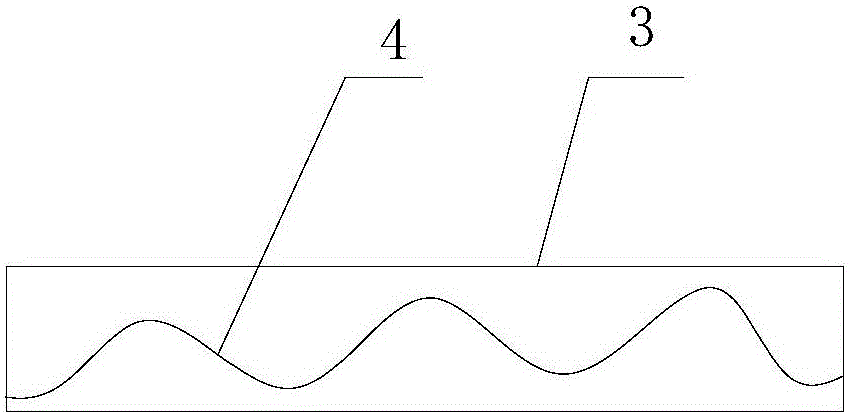

[0038] Such as figure 2 As shown, the stress-resisting structure 4 is a sub-conductor that can undergo tensile and compressive deformation on the conductor 2, and the sub-conductor is distributed in a sinusoidal curve in the bending area 3, that is, the sub-conductor is a section with crests and troughs. of wavy lines. Moreover, the sub-wires are arranged transversely through the bending area 3 . When the bending area 3 is bent, the sub-wire will release stress along the direction of tension and compression during the bending process, so as to avoid the breakage of the wire or the separation of the wire from the substrate, which greatly...

Embodiment 3

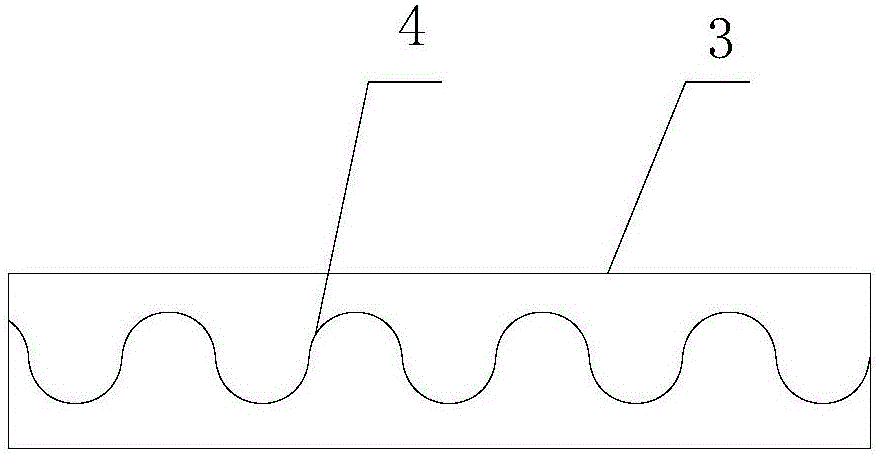

[0040] Such as image 3 As shown, in order to increase the effect of releasing the stress, the third embodiment is improved on the basis of the second embodiment, and the shape of the sub-conductors is changed to a continuous "S" shape distribution, that is, the sub-conductors are distributed in the bending area 3 It is distributed in a continuous "S" shape. This continuous "S" shape can be understood as a plurality of English letters "S" connected in sequence and transversely running through the bending area 3 . Wherein, the letter "S" is used as an example to explain and illustrate for the convenience of understanding, and other shapes similar to the letter "S" also belong to the protection scope of the third embodiment. Moreover, since the bending length of the sub-conductor in the third embodiment is greater than that of the sub-conductor in the second embodiment within the range of unit length, it can release greater stress when it is bent, and the stress is released dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com