Polymer-matrix composite material and preparation method thereof

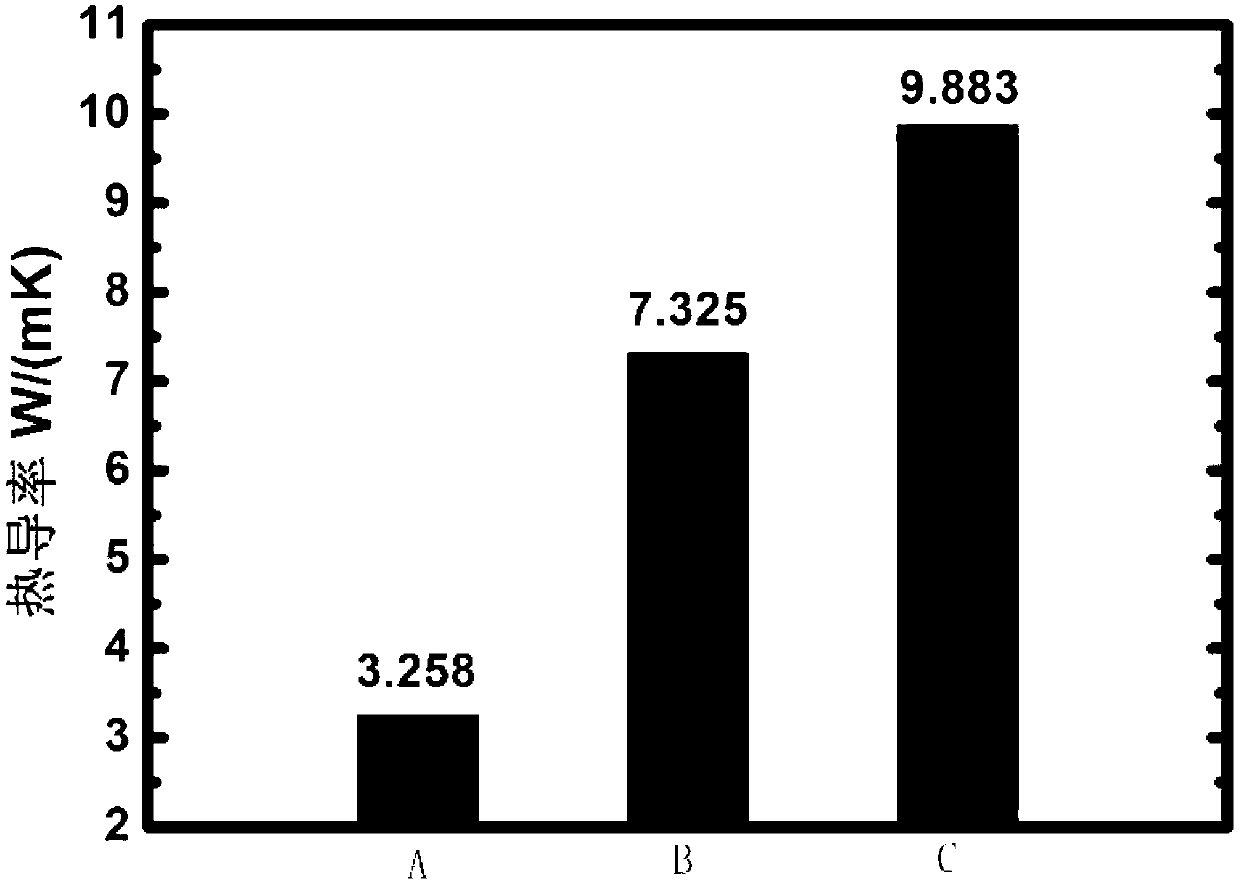

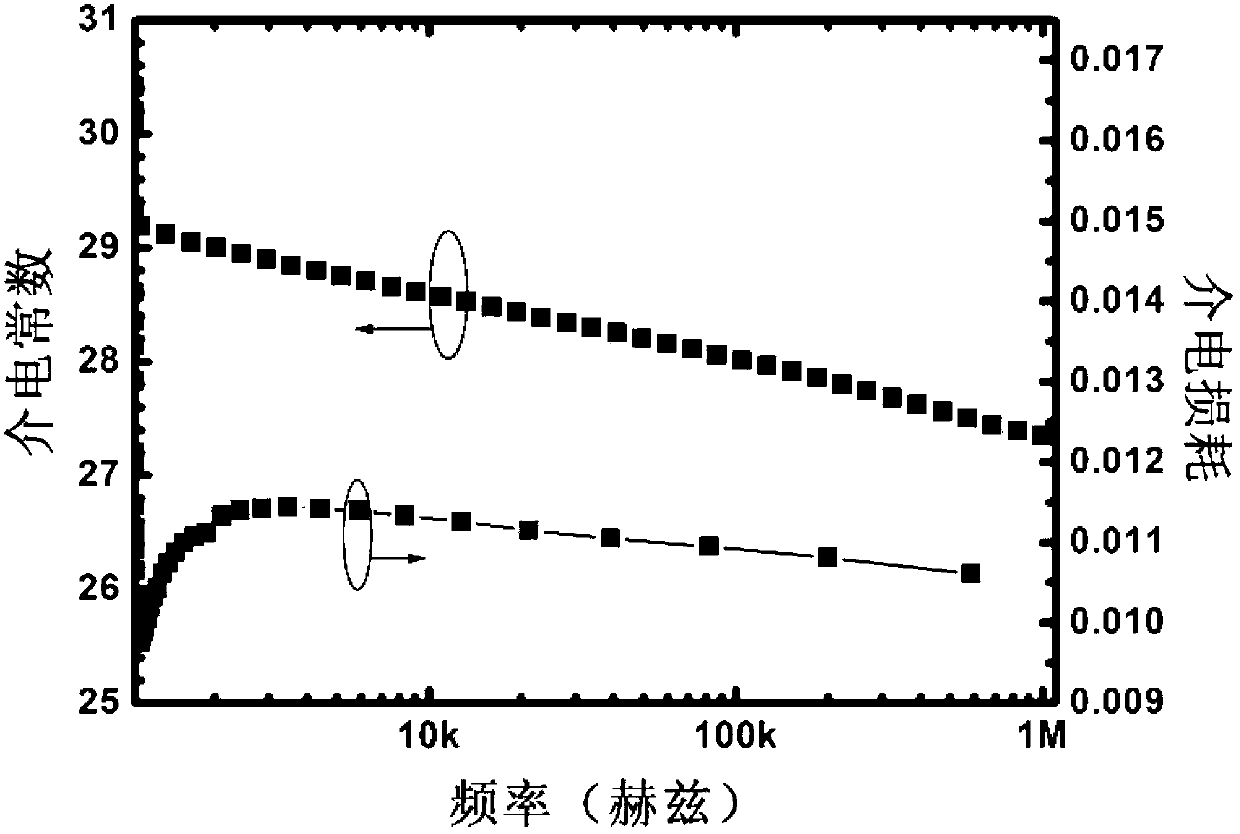

A technology of composite materials and polymers, applied in the field of polymer-based composite materials and their preparation, to achieve the effects of simple preparation process, improvement of thermal conductivity and dielectric constant, and optimization of thermal conductivity and dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

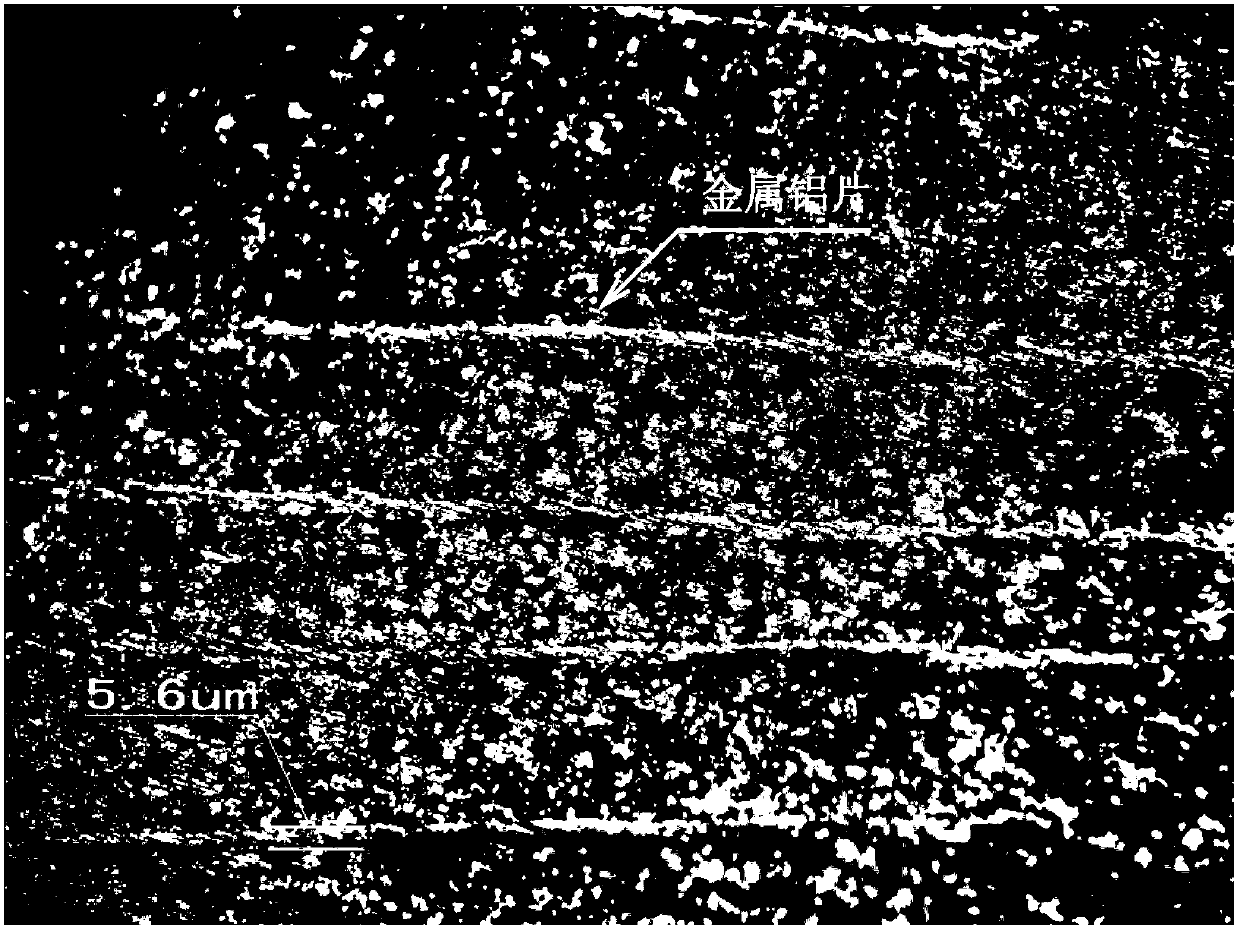

[0033] Provided in this example, PVDF is used as a matrix, and fillers are prepared from flake-shaped metal and metal passivation particles to prepare polymer-based composite materials. Metal fillers and PVDF in the composite materials are weighed according to the conversion of 50% of the volume fraction. Its preparation includes the following steps:

[0034] 1) Take metal aluminum powder particles, which are pure aluminum powder without other impurities as tested by XRD, and crush the metal aluminum powder particles into two kinds of powders with a particle size of about 10 μm and a nanometer size of about 50 nm;

[0035] 2) Take 10g of the crushed micron-sized metal powder, dry it at 120°C for 3 hours after introducing an appropriate amount of oxygen, pass through a 120-mesh sieve to disperse the dried agglomerated metal powder, and obtain passivated metal aluminum powder with uniform micron size powder;

[0036] 3) Same as step 2, to obtain passivation powder of metal alum...

Embodiment 2

[0045] In this example, PVDF is used as the matrix, the filler is prepared from fibrous aluminum metal and metal passivation particles, and the polymer-based composite material is prepared. The metal filler and PVDF in the composite material are weighed according to the conversion of 50% of the volume fraction. , its preparation includes the following steps:

[0046] 1) Take metal aluminum powder particles, which are pure aluminum powder without other impurities as tested by XRD, and crush the metal aluminum powder particles into two kinds of powders with a particle size of about 10 μm and a nanometer size of about 50 nm;

[0047] 2) Take 10g of the crushed micron-sized metal powder, dry it at 120°C for 4 hours after introducing an appropriate amount of oxygen, pass through a 120-mesh sieve to disperse the dried agglomerated metal powder, and obtain a passivated metal aluminum powder with uniform micron size powder;

[0048] 3) Same as step 2, to obtain passivation powder of ...

Embodiment 3

[0054] In this example, PI is used as the matrix, and fillers are prepared from flake metal and metal passivation particles to prepare polymer-based composite materials. The metal fillers and PI in the composite materials are weighed according to the conversion of 50% of the volume fraction. Its preparation includes the following steps:

[0055] 1) Take metal aluminum powder particles, which are pure aluminum powder without other impurities as tested by XRD, and crush the metal aluminum powder particles into two kinds of powders with a particle size of about 10 μm and a nanometer size of about 50 nm;

[0056] 2) Take 10g of the crushed micron-sized metal powder, dry it at 120°C for 5 hours after passing in an appropriate amount of oxygen, pass through a 120-mesh sieve to disperse the dried agglomerated metal powder, and obtain passivated metal aluminum powder with uniform micron size powder;

[0057] 3) Same as step 2, to obtain passivation powder of metal aluminum powder wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com