Low-themogenesis super-wear-resisting carbon black and production technology thereof

A super wear-resistant carbon black and production process technology, applied in the direction of fibrous fillers, etc., can solve the problems of unfavorable vulcanized rubber heat generation performance, narrow distribution, etc., to achieve good quality carbon black products, super wear resistance, and significant economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: A super wear-resistant carbon black with high structure and low heat generation, which uses a mixture of anthracene oil and coal tar with a weight ratio of 8.5:1.5 as raw material oil, natural gas as fuel, no additives, and super wear-resistant carbon black It is prepared by the production process of grinding furnace and black furnace method; the raw material oil processing capacity ranges from 4000 to 4300kg / h. The water content of various oil products in the raw oil must be less than 2%, the density should be between 1.09-1.21g / ml, and the oil yield should not be less than 50%.

Embodiment 2

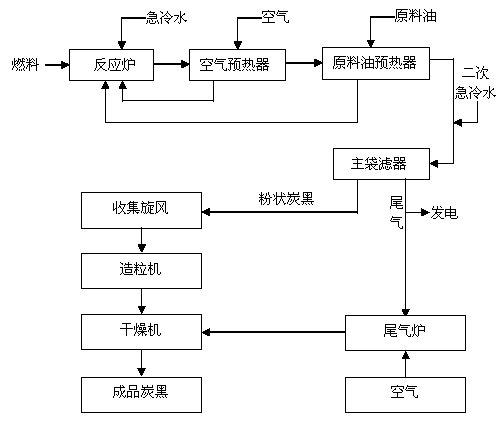

[0030] Embodiment 2: produce the super wear-resistant carbon black of the high structure low heat generation described in embodiment 1 with super wear-resistant furnace black furnace method, the concrete steps of production technology are as follows:

[0031] (1) The air compressed to 170Kpa is preheated to 750°C by the air preheater, and sent to the air distribution room of the reaction furnace through the hot air pipeline;

[0032] (2) Send the fuel into the combustion chamber of the reaction furnace, mix and burn with the hot air sent from the air distribution chamber above, and control the temperature at 1918°C. After the raw oil is preheated to 200°C by the raw oil preheater, it is sprayed into the throat section of the reaction furnace, atomized and sheared, and cracked for 10 milliseconds in the reaction section of the reaction furnace (the temperature of the reaction section is 1650 ℃), producing carbon black smoke;

[0033] (3) The carbon black flue gas is quenched o...

Embodiment 3

[0036] Embodiment 3: A super wear-resistant carbon black with high structure and low heat generation, which uses a mixture of anthracene oil and coal tar with a weight ratio of 9:1 as raw material oil, natural gas as fuel, no additives, and super-resistant carbon black It is prepared by the production process of grinding furnace and black furnace method; the processing capacity of raw material oil ranges from 3900 to 4200kg / h. The water content of various oil products in the raw oil must be less than 2%, the density should be between 1.09-1.21g / ml, and the oil yield should not be less than 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com