High-functionality degree polyester polyol and preparation method thereof

A polyester polyol, high-functionality technology, used in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, plastic recycling, etc., can solve the problem of single catalyst, decreased thermal stability of foam, polyester The problem of high viscosity of polyols can improve the damage effect, reduce the viscosity of the product, and expand the molecular distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

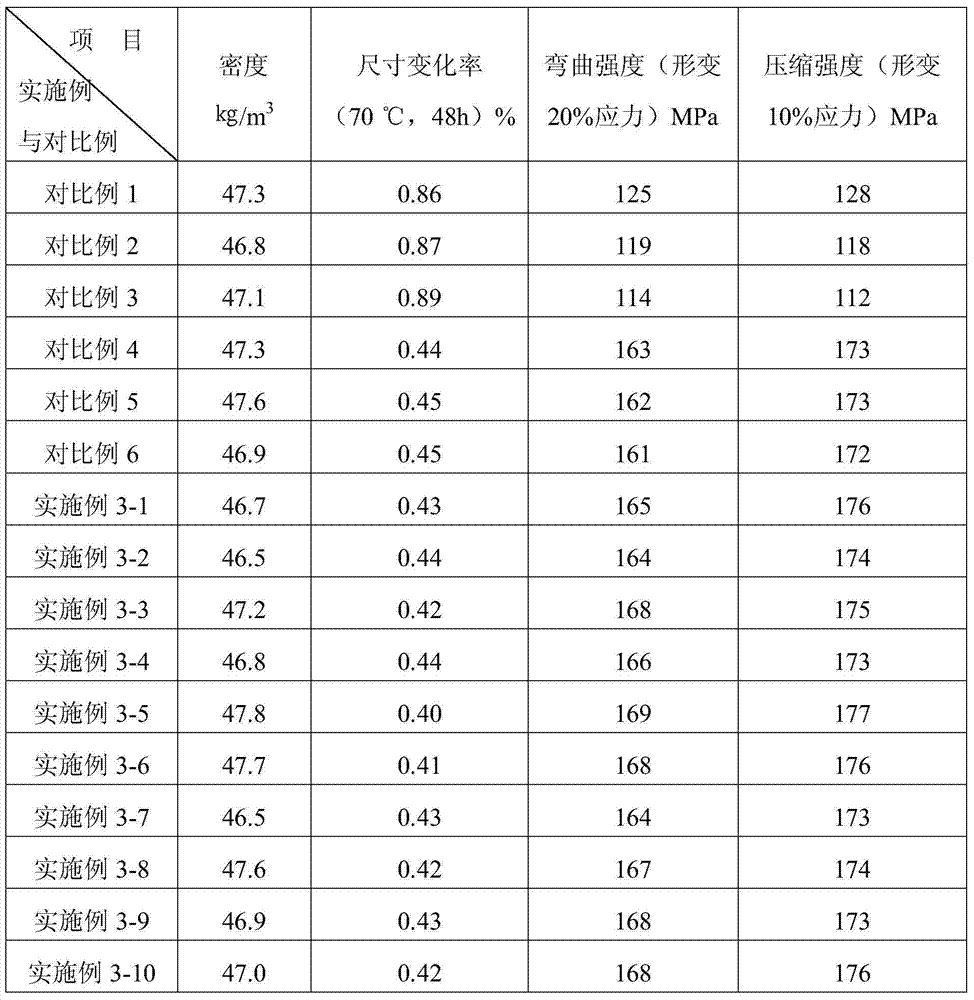

Examples

Embodiment 1-1

[0045] Put 1000kg of polyester chips (η=0.85dl / g), 1000kg of diethylene glycol, 0.8kg of zinc acetate, and 0.8kg of n-butyl titanate into reactor A, blow in nitrogen, stir and raise the temperature to 235°C, and keep the temperature constant Stir for 20 minutes to completely dissolve the polyester chips, then slowly raise the temperature to 240°C, and carry out the alcoholysis reaction at a constant temperature for 6 hours under the protection of nitrogen. When the amount of ethylene glycol removed by the distillation column of reactor A reaches 48 kg and the After the viscosity of the product reaches 1100-1200mPa·S at 25°C, the reaction is stopped, the temperature is lowered to 160°C, and impurities are filtered with diatomaceous earth to obtain the polyester alcoholysis solution.

Embodiment 1-2

[0047] Put 1000kg of recovered PET film powder (η=0.73dl / g), 1000kg of diethylene glycol, 0.6kg of zinc acetate, and 0.6kg of n-butyl titanate into reactor A, blow in nitrogen, stir and heat up to 240°C , stirred at constant temperature for 20 minutes to completely dissolve the recovered PET film, then slowly raised the temperature to 240°C, and carried out alcoholysis reaction at constant temperature for 8 hours under the protection of nitrogen, when the amount of ethylene glycol removed by the rectifying column of reactor A reached 50kg After the viscosity of the reactant reaches 1100-1200 mPa·S at 25°C, the temperature is lowered to 160°C, and impurities are filtered through diatomaceous earth to obtain the polyester alcoholysis solution.

Embodiment 1-3

[0049] Put 1000kg of recovered polyester chips (η=0.55dl / g), 1000kg of glycerin, 0.7kg of zinc acetate, and 0.6kg of n-butyl titanate into reactor A, blow in nitrogen, stir and raise the temperature to 235°C, and stir at a constant temperature 20 minutes to completely dissolve the recycled polyester chips, then slowly raise the temperature to 245°C, and carry out the alcoholysis reaction at a constant temperature for 7 hours under the protection of nitrogen. After the viscosity of the product reaches 1100-1200mPa·S at 25°C, the temperature is lowered to 160°C, and impurities are filtered with diatomaceous earth to obtain the polyester alcoholysis solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com