Preparation method of amorphous silicon powder body, amorphous silicon powder body and lithium ion battery

A technology of amorphous silicon and powder, which is applied in the field of amorphous silicon preparation, can solve the problems of restricting the application of amorphous silicon negative electrode materials, difficulty in mass production, and low utilization rate of raw materials, so as to reduce the phenomenon of powdering and falling off, and is easy to operate , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In a first aspect, this embodiment provides a method for preparing amorphous silicon powder, comprising the following steps:

[0045] Using metallurgical grade silicon as raw material, the mother ingot is made by smelting;

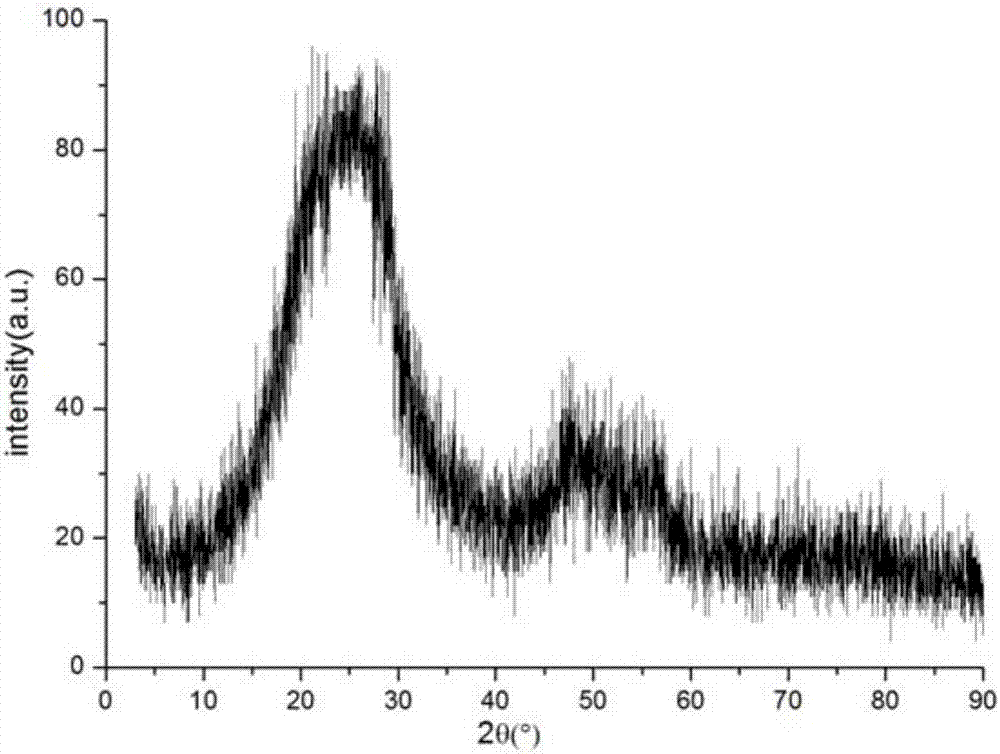

[0046] Swinging the master ingot by means of single-roll rapid solidification to obtain an amorphous silicon strip;

[0047] subjecting the amorphous silicon strip to embrittlement treatment to obtain an embrittled strip;

[0048] The brittle strip is pulverized to obtain amorphous silicon powder.

[0049] According to statistics, more than 25.7% of silicon is contained on the surface of the earth, and pure silicon crystals rarely exist in nature, and silicon usually exists in silicon dioxide (also known as silica) and silicate. Silicon can generally be divided into the following grades: industrial silicon, metallurgical grade silicon, solar grade silicon and electronic energy grade silicon; among them, solar grade silicon and electronic energy gr...

Embodiment 1

[0106] A preparation method of amorphous silicon powder, comprising the following steps:

[0107] (a) Smelting: using metallurgical grade silicon as raw material, smelting in a non-consumable vacuum electric arc furnace to obtain a master ingot;

[0108] (b) Amorphous strip stripping: use an amorphous strip stripping machine to strip the mother ingot in a single-roller rapid solidification method to obtain an amorphous silicon strip;

[0109] (c) Embrittlement treatment: subjecting the amorphous silicon strip to embrittlement treatment to obtain an embrittlement strip;

[0110] (d) Pulverization treatment: pulverize the embrittled strip to obtain amorphous silicon powder.

Embodiment 2

[0112] A preparation method of amorphous silicon powder, comprising the following steps:

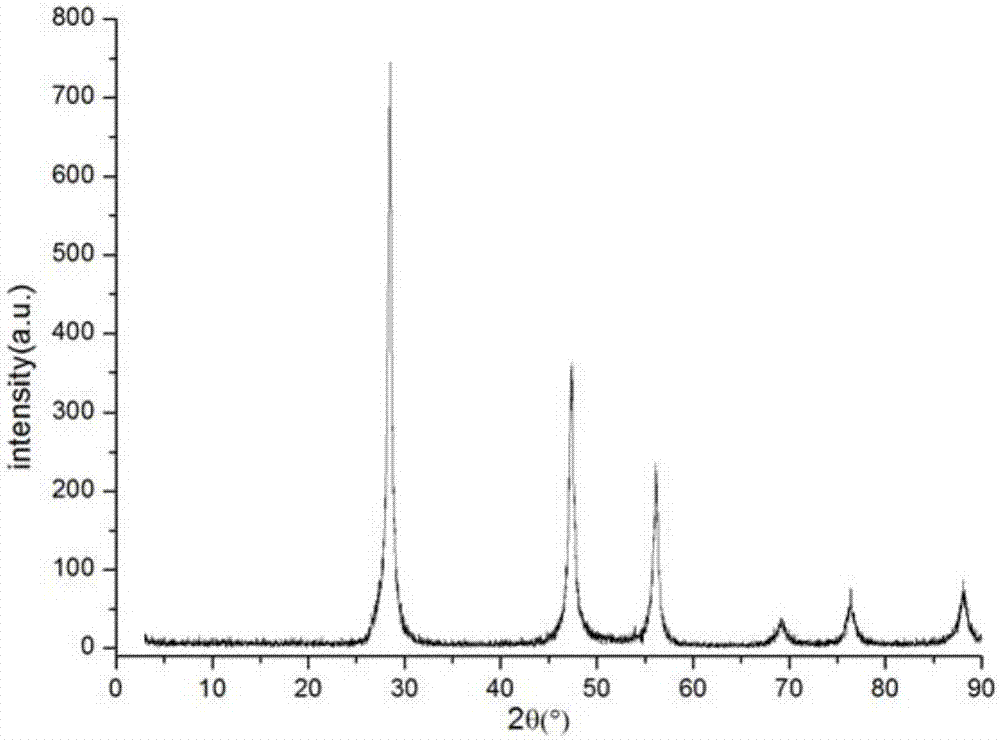

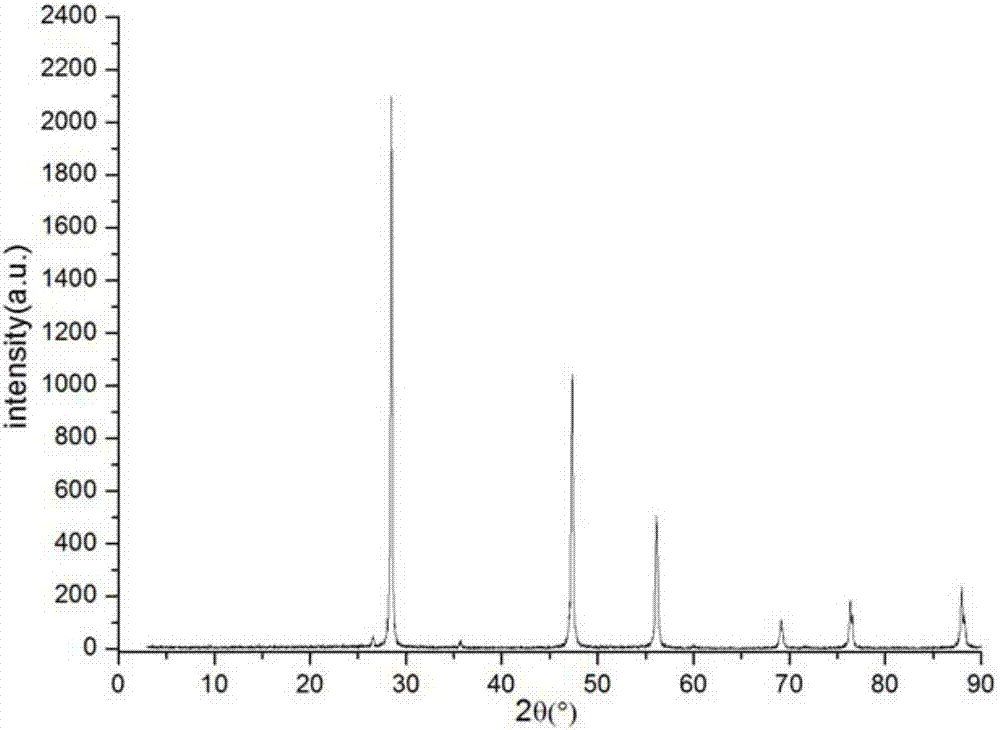

[0113] (a) Melting: Metallurgical grade silicon is used as raw material, and the silicon content in metallurgical grade silicon is 98wt%. Non-consumable vacuum electric arc furnace is used for smelting. First, the non-consumable vacuum electric arc furnace is evacuated. stop pumping at the time, and then charge 0.6atm argon to carry out arc melting, the melting current is 110A, the melting time is 2min, and the number of times of melting is 3 times, and the mother ingot is obtained;

[0114] (b) Amorphous tape stripping: The mother ingot is stripped by using an amorphous strip machine to quickly solidify with a single roller, and the strip furnace in the amorphous strip machine is vacuumed, and it stops when the vacuum reaches 0.01Pa Evacuate, and then fill with 0.3atm argon; the linear speed of the copper roller in the amorphous belt throwing machine is 40m / s, the cooling water with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com