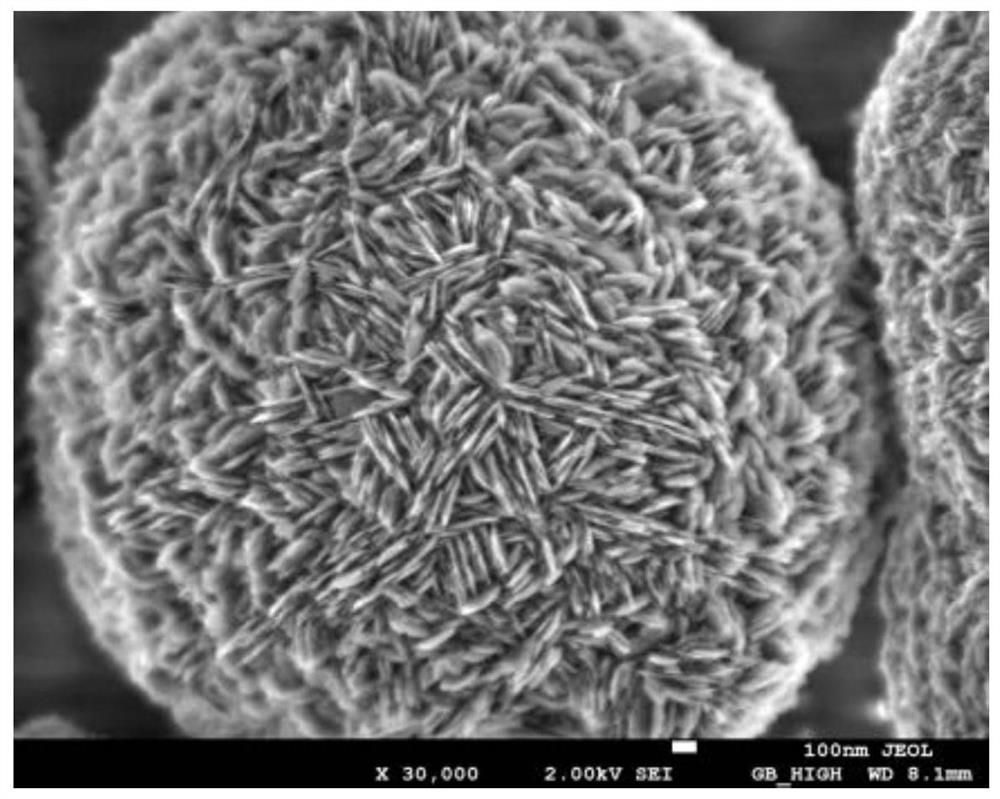

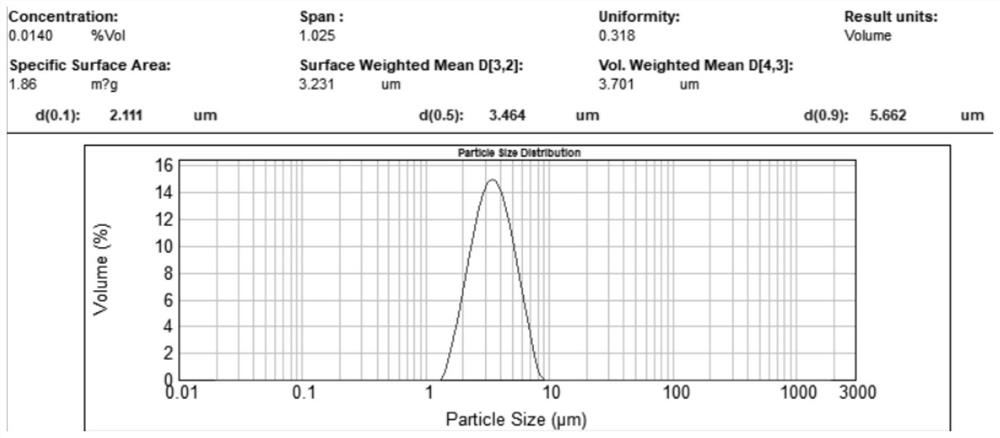

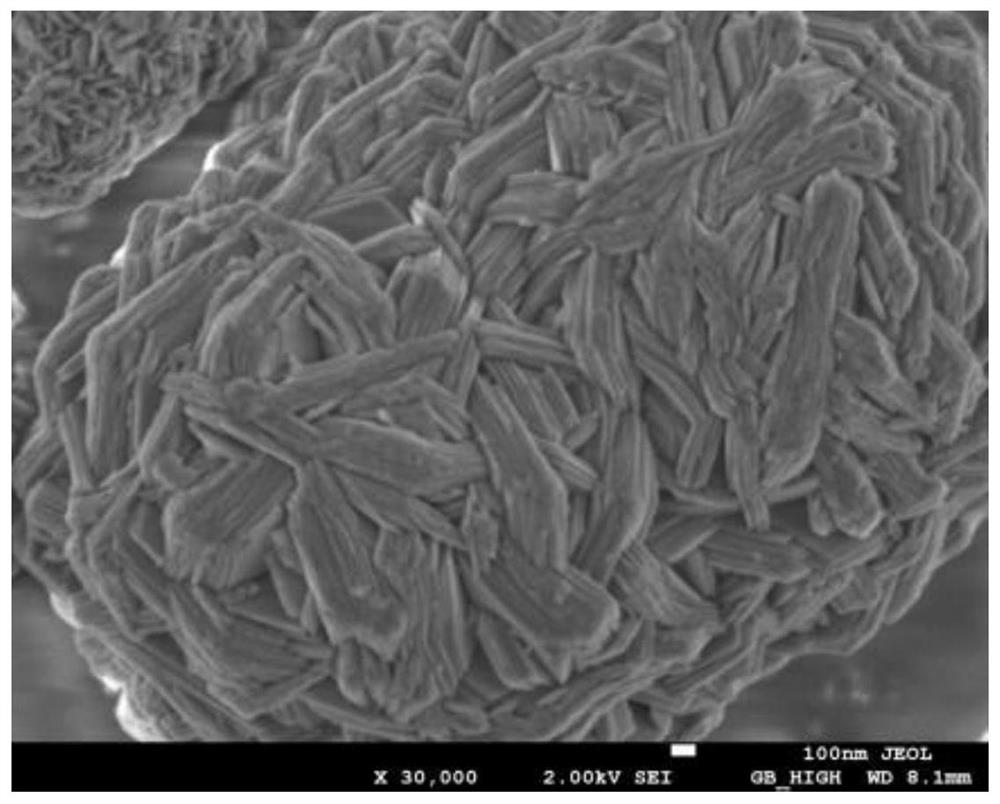

High-nickel single-crystal small-particle ternary precursor and continuous preparation method thereof

A precursor, small particle technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of mixed arrangement of nickel and lithium cations, high cost, low yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A continuous preparation method of a high-nickel single crystal small particle ternary precursor, the preparation method comprising the following steps:

[0054] Step 1. Put Ni 2+ 、Co 2+ , Mn 2+ According to the general formula Ni 0.83 co 0.11 mn 0.06 (OH) 2 Prepare a soluble ternary mixed salt solution in the molar ratio of the corresponding elements.

[0055] Add H to the ternary mixed salt solution 2 o 2 and additive to get mixed solution, said additive is selected diethylamine pentaacetic acid for use, said additive and Ni 2+ 、Co 2+ , Mn 2+ Complexation to stabilize H 2 o 2 , H 2 o 2 will part of Mn 2+ Oxidized to Mn 3+ , to realize the refinement of the primary particle of the secondary particle and increase the specific surface area; the Mn in the mixed solution 2+ with H 2 o 2 The molar ratio of is 3.0. The concentration of the additive in the mixed solution is 0.4 mol / L, Ni 2+ 、Co 2+ , Mn 2+ The total molar concentration is 2.0mol / L.

[0...

Embodiment 2

[0065] A continuous preparation method of a high-nickel single crystal small particle ternary precursor, the preparation method comprising the following steps:

[0066] Step 1. Put Ni 2+ 、Co 2+ , Mn 2+ According to the general formula Ni 0.90 co 007 mn 0.03 (OH) 2 Prepare a soluble ternary mixed salt solution in the molar ratio of the corresponding elements.

[0067] Add H to the ternary mixed salt solution 2 o 2 and additive to get mixed solution, said additive is selected diethylamine pentaacetic acid for use, said additive and Ni 2+ 、Co 2+ , Mn 2+ Complexation to stabilize H 2 o 2 , H 2 o 2 will part of Mn 2+ Oxidized to Mn 3+ , to realize the refinement of the primary particle of the secondary particle and increase the specific surface area; the Mn in the mixed solution 2+ with H 2 o 2 The molar ratio of is 3.0. The concentration of the additive in the mixed solution is 0.5 mol / L, Ni 2+ 、Co 2+ , Mn 2+ The total molar concentration is 2.0mol / L.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com