Method for three-dimensionally printing honeycomb-type solid oxide fuel cell with three-dimensional channel

A solid oxide and fuel cell technology, which is applied in solid electrolyte fuel cells, fuel cell components, fuel cells, etc., can solve problems such as high cost, unstable batch performance, and reduced effective area of the membrane to reduce product cost. The impact of quality, the elimination of batch instability, and the effect of saving preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

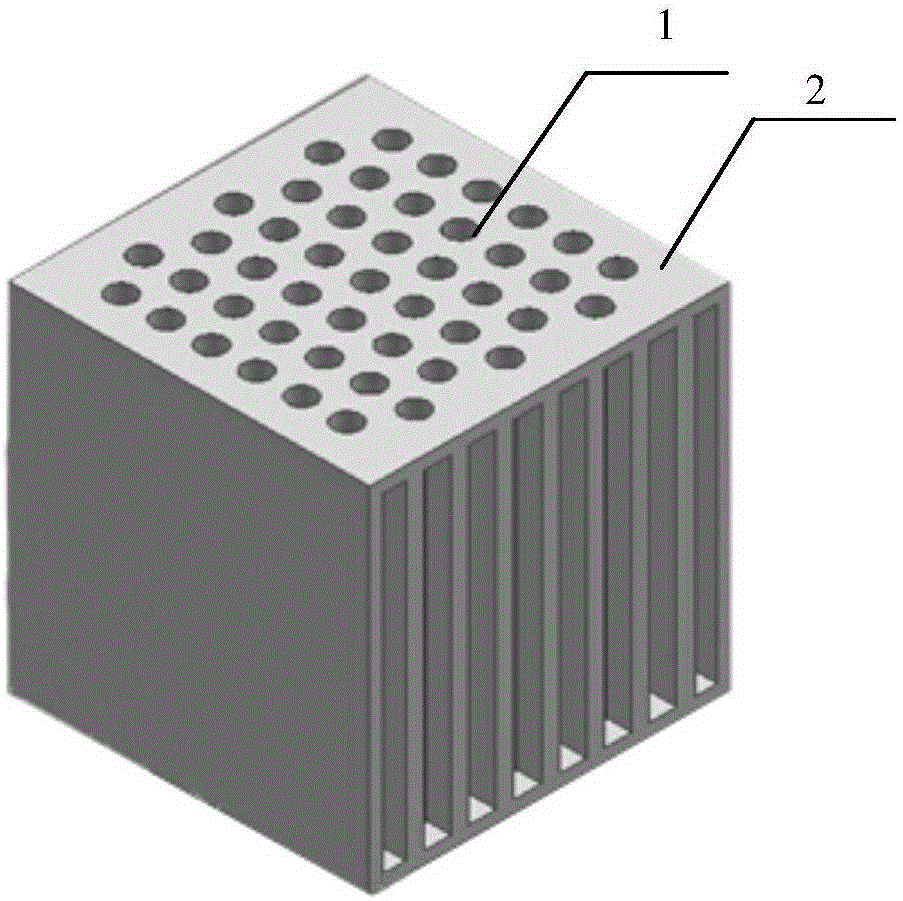

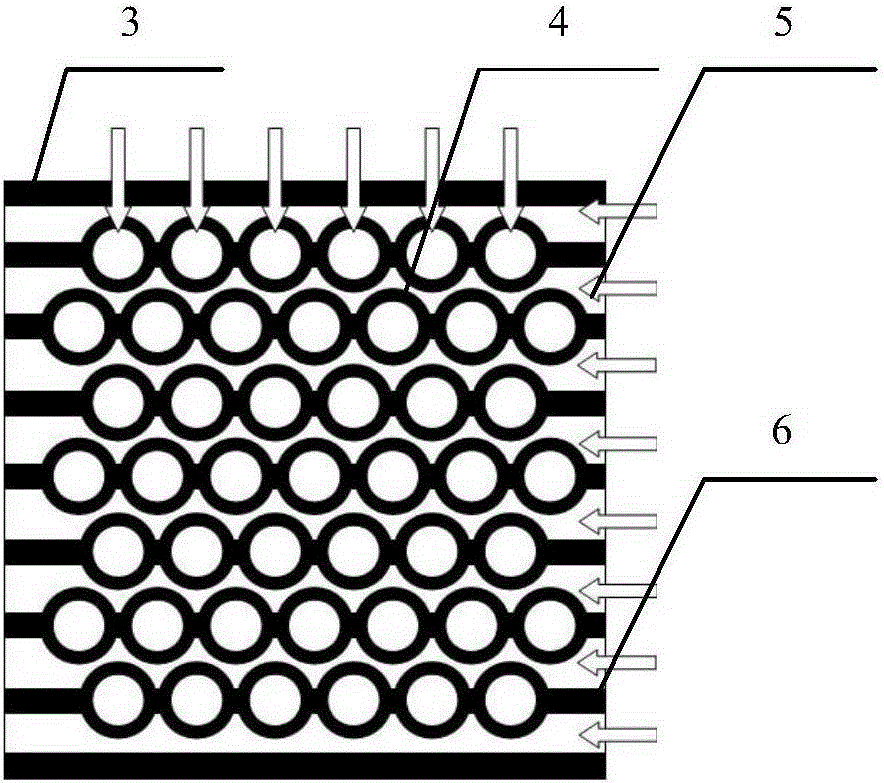

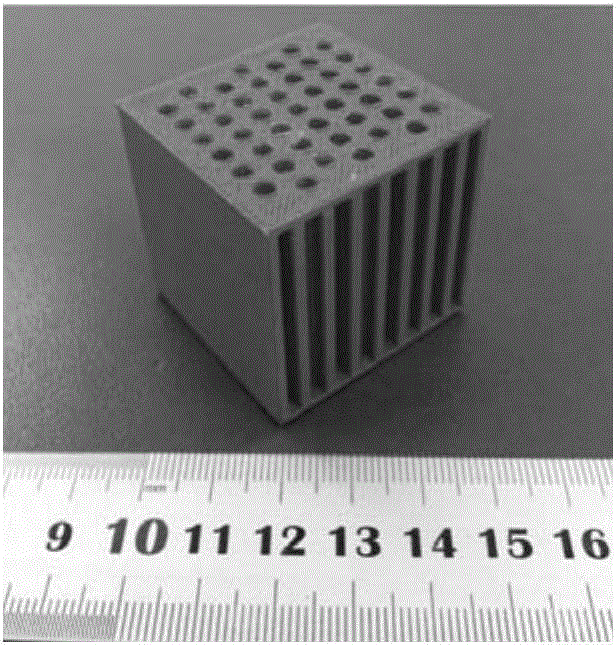

[0045] 300gLSCF (La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-δ ) The ceramic cathode powder, 10g of dextrin and spherical graphite are uniformly mixed with a mixer, and placed in a three-dimensional printer raw material box after passing through a 60-mesh sieve. The three-dimensional printer adopts the Z510 ceramic three-dimensional printer of the Zcorp Company of the United States, and uses ug software to draw the three-dimensional solid model structure diagram of the support body, see figure 1 , using a computer-controlled three-dimensional printer to print the LSCF ceramic powder according to the designed three-dimensional solid model structure diagram, and obtain a honeycomb ceramic cathode support body green body with a three-dimensional channel structure. The external dimensions of the model are 4cm in length, width, and height. There are 45 ceramic microtubes in the longitudinal direction to provide the tube-side fluid channels, and 8 channels in the horizontal direction to pro...

Embodiment 2

[0049] 400g of Ni-YSZ ceramic anode powder, 20g of polyvinyl butyral powder and spherical graphite were evenly mixed with a mixer, passed through a 60-mesh sieve and placed in a three-dimensional printer raw material box. The three-dimensional printer adopts the Z510 ceramic three-dimensional printer of Zcorp Company of the United States, and uses the 3Dmax software to draw the three-dimensional solid model structure diagram of the support body, see figure 1 , using a computer-controlled three-dimensional printer to print the Ni-YSZ ceramic powder according to the designed three-dimensional solid model structure diagram, and obtain a honeycomb ceramic anode support body green body with a three-dimensional channel structure. The external dimensions of the model are 4cm in length, width, and height. There are 45 ceramic microtubes in the longitudinal direction to provide the tube-side fluid channels, and 8 channels in the horizontal direction to provide the fluid channels between...

Embodiment 3

[0053] 450gLa 2 NiO 4-δ The ceramic cathode powder and 20 g of starch are evenly mixed by a ball mill, passed through a 60-mesh sieve, and placed in a three-dimensional printer raw material box. The three-dimensional printer adopts Zcorp Z510 ceramic three-dimensional printer of the United States, uses catia software to draw the three-dimensional solid model structure diagram of the support body, and uses the computer to control the three-dimensional printer to print the ceramic powder according to the designed three-dimensional solid model structure diagram to obtain a three-dimensional channel structure The green body of the honeycomb ceramic membrane module. The green body is purged to clean the powder residue on the surface, placed in a programmable temperature-controlled electric furnace, first dried at 85°C for 2 hours, then heated to 500°C at a heating rate of 2°C / min, and kept for 2 hours to remove organic matter in the film. Binder. Then heat it up to 1350°C at a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com