Siloxane modified cardanol derivative prepolymer as well as preparation method and application thereof

A technology of siloxane modification and cardanol, which is applied in the direction of polyurea/polyurethane coatings and coatings, can solve the problems of non-compliance with environmental protection, and improve storage stability, batch stability, process equipment and operating environment less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

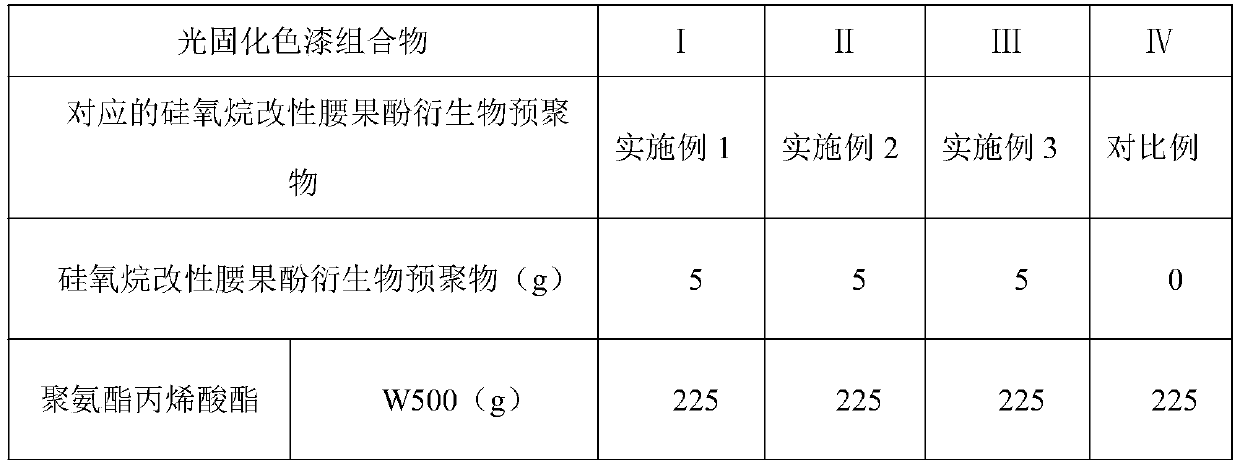

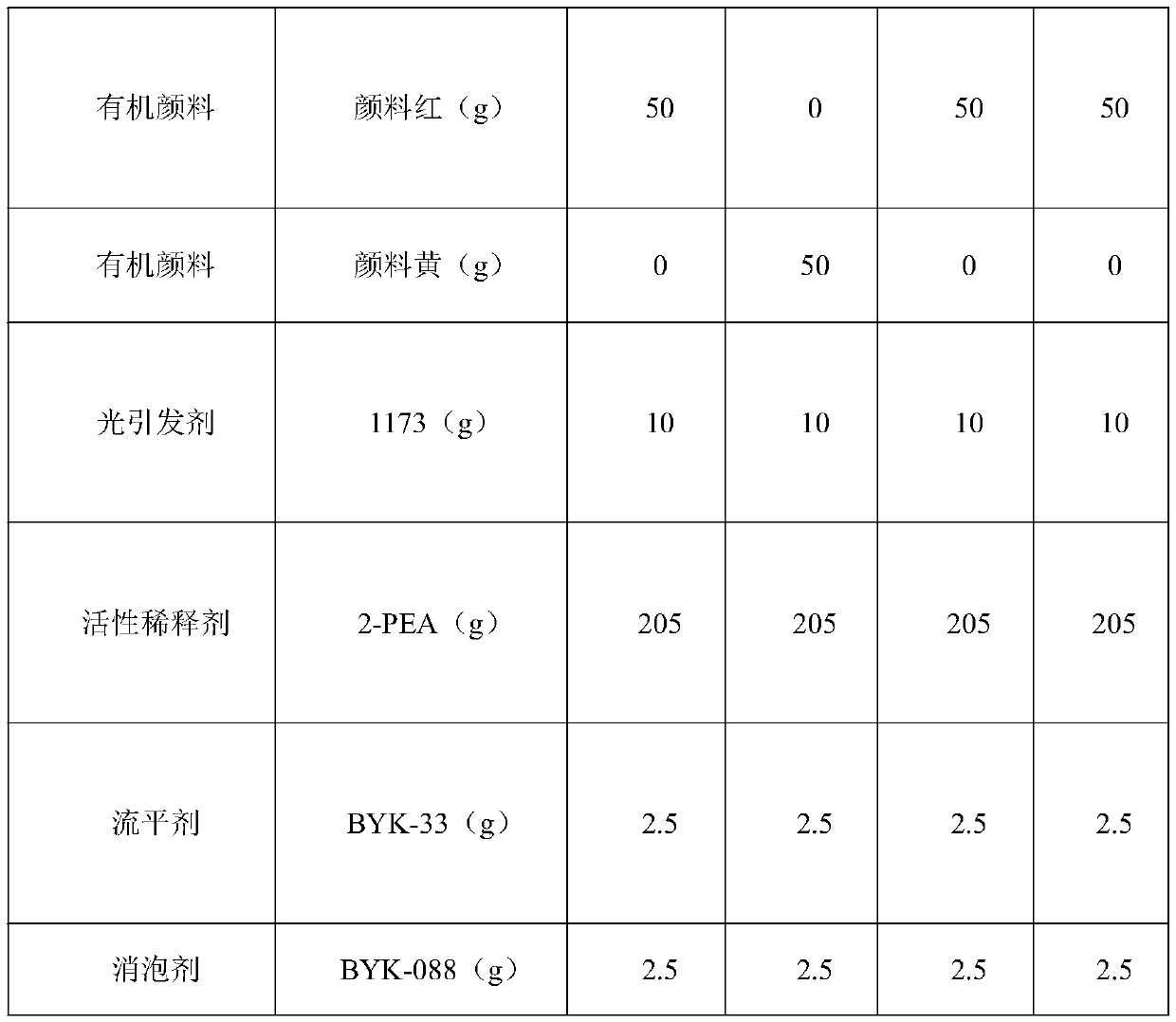

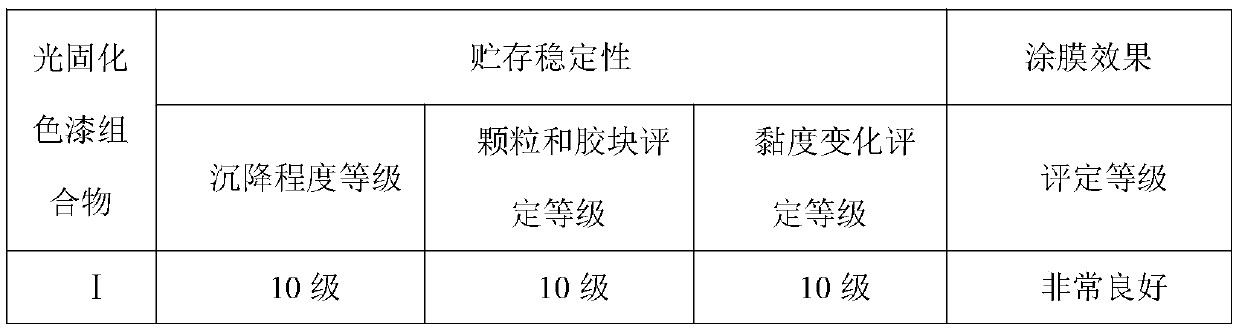

Examples

Embodiment 1

[0025] Put cashew nut shell oil polyester diol (viscosity of 1400cps at 25°C, hydroxyl value of 75mgKOH / g), 3-isocyanate propyltrimethoxysilane, organic bismuth catalyst into the equipment equipped with high and low temperature circulation pump, thermometer and stirring In the reaction kettle of the rod, the whole process is protected by nitrogen, and the reaction is carried out at a constant temperature of 90°C for 4 hours, and then samples are taken every 0.5 hours using a Fourier transform infrared spectrometer to monitor the characteristic peak of NCO. When the NCO peak completely disappears, the material is cooled and filtered to obtain silicon Oxyalkylene modified cardanol derivative prepolymer. Among them, the molar ratio of the OH of cashew nut shell polyester diol to the NCO of 3-isocyanatopropyl trimethoxysilane is 1:0.5, and the organic bismuth catalyst is cashew nut shell oil polyester diol and 3-isocyanatopropyl trimethoxysilane. 0.2‰ of the total weight of trimet...

Embodiment 2

[0027] Put cashew nut shell oil phenolic resin diol (viscosity of 1000cps at 25°C, hydroxyl value of 175mgKOH / g) 3-isocyanatopropylmethyldimethoxysilane and organic bismuth catalyst into the equipment equipped with high and low temperature circulating pumps and thermometers. In the reaction kettle with a stirring rod, under nitrogen protection throughout the whole process, react at a constant temperature of 80°C for 6h, and then take samples every 0.5h and use a Fourier transform infrared spectrometer to monitor the NCO characteristic peak. When the NCO peak disappears completely, cool down and filter the material to prepare A siloxane-modified cardanol derivative prepolymer was obtained. Among them, the molar ratio of the OH of cashew nut shell oil phenolic resin diol to the NCO of 3-isocyanatopropylmethyldimethoxysilane is 1:1, and the organic bismuth catalyst is cashew nut shell oil phenolic resin diol and 3- 0.6‰ of the total weight of isocyanatopropylmethyldimethoxysilane...

Embodiment 3

[0029] Put cashew nut shell oil branched polyol (viscosity of 2900cps at 25°C, hydroxyl value of 175mgKOH / g), 3-isocyanatopropyltriethoxysilane, organic bismuth catalyst into the equipment equipped with high and low temperature circulation pump, thermometer and In the reaction kettle with a stirring rod, under nitrogen protection throughout the whole process, react at a constant temperature of 85°C for 5 hours, and then take samples every 0.5 hours and use a Fourier transform infrared spectrometer to monitor the NCO characteristic peak. When the NCO peak completely disappears, cool down and filter the material to obtain Siloxane-modified cardanol derivative prepolymer. Among them, the molar ratio of the OH of cashew nut shell oil branched chain polyol to the NCO of 3-isocyanatopropyltriethoxysilane is 1:0.8, and the organic bismuth catalyst is cashew nut shell oil branched chain polyol and 3-isocyanate group 0.4‰ of the total weight of propyltriethoxysilane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com