Variable diffuser structure of centrifugal machine and centrifugal machine

A diffuser and centrifuge technology, applied in the field of centrifuges, can solve the problems such as the small gas flow adjustment range of the centrifugal compressor and the easy entry of the centrifuge into the surge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

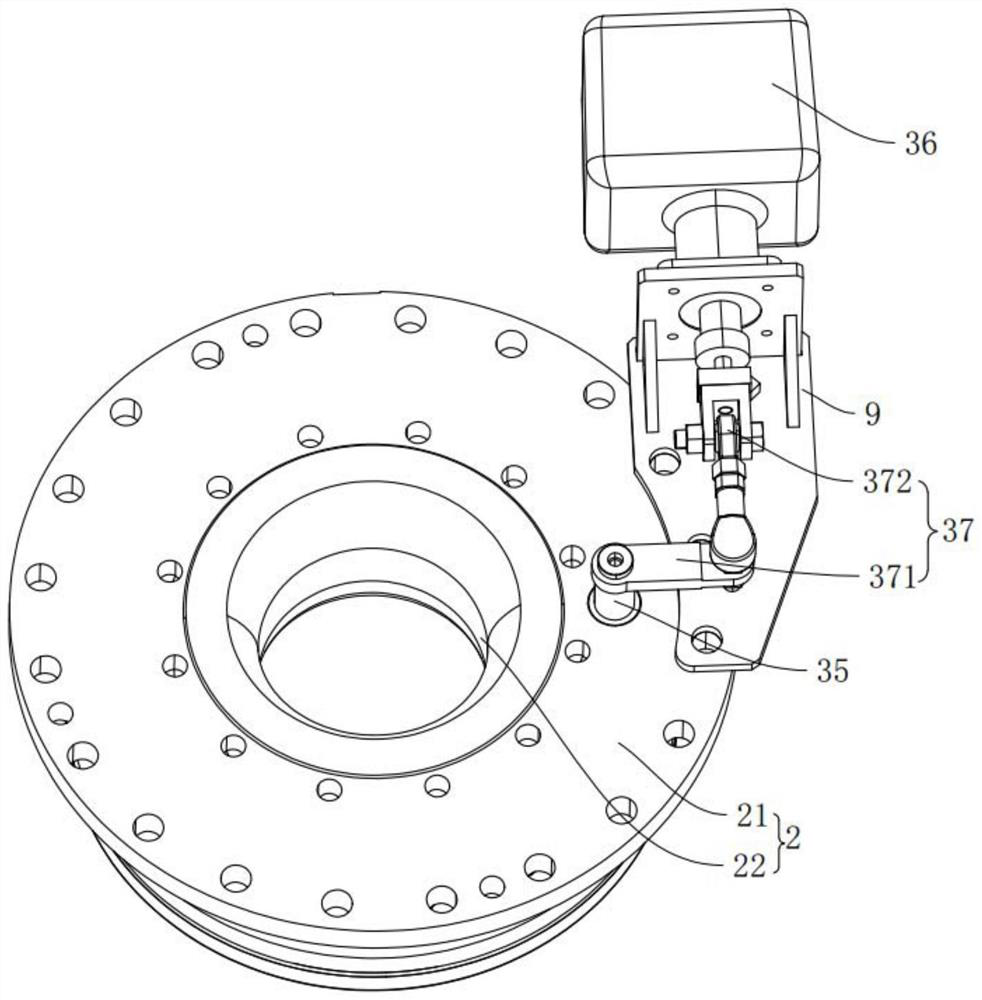

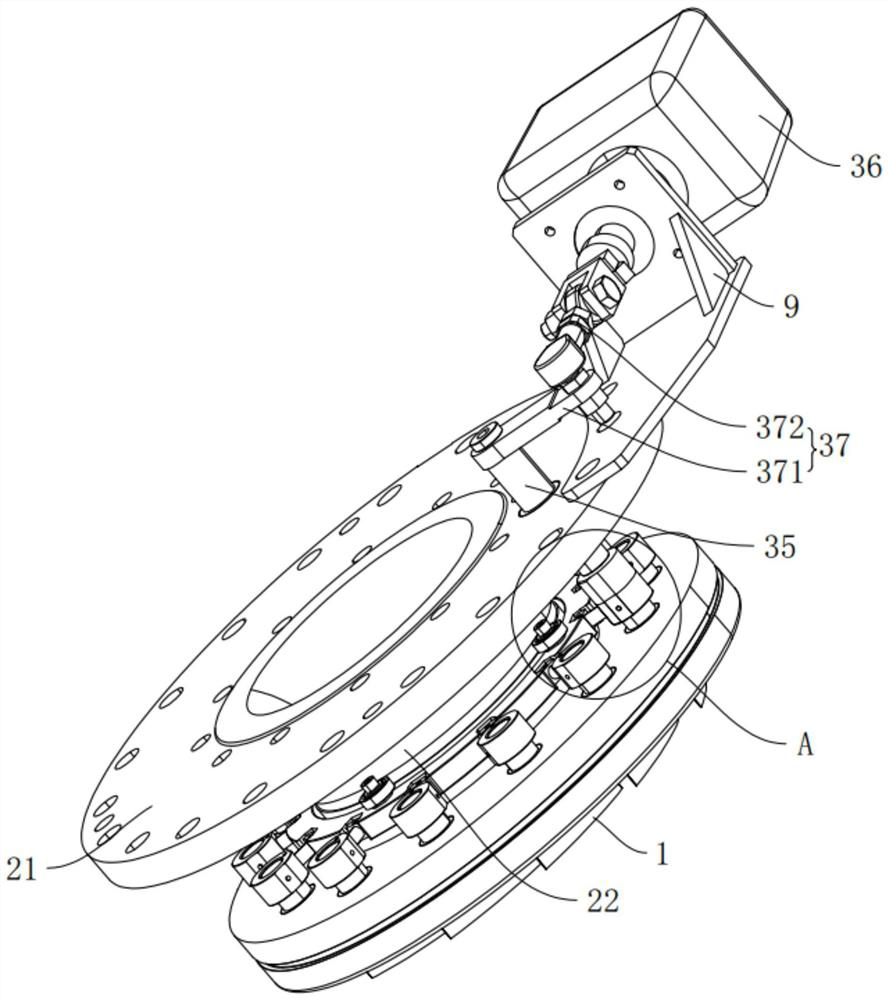

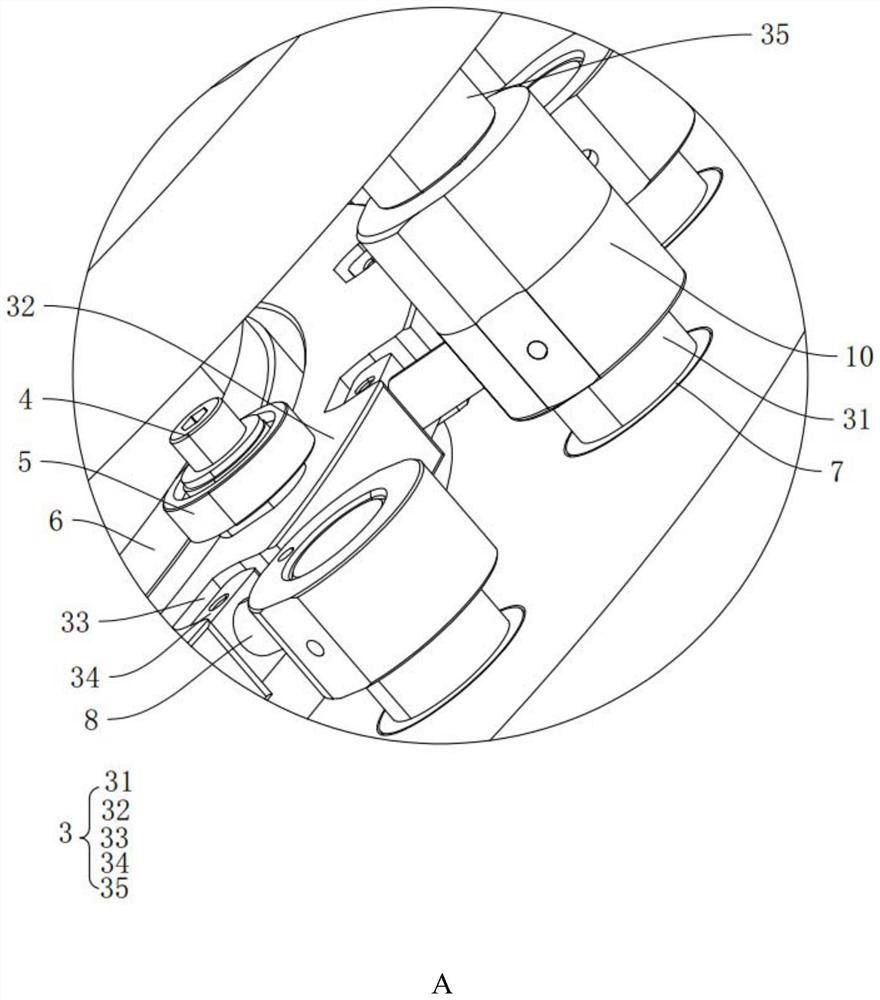

[0038] refer to Figure 1-Figure 4 As shown, the present invention provides a centrifuge, including a variable diffuser structure of the centrifuge, and the variable diffuser structure of the centrifuge includes a deflector 2, a plurality of diffuser blades 1 and a connecting rod driver 3; A plurality of diffuser blades 1 are evenly arranged in a ring on one side of the guide body 2, and are rotatably connected with the guide body 2; the connecting rod driver 3 is used to simultaneously drive the plurality of diffuser blades 1 to rotate in the same direction.

[0039] When in use, multiple diffuser blades 1 are driven to rotate in the same direction through the connecting rod driver 3, so that multiple diffuser blades 1 can be rotated and switched synchronously at the same time to achieve the purpose of adjusting the flow area of the exhaust port. Then, in cooperation with the guide vane mechanism, the two mechanisms are driven by the actuator 36 at the same time, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com