A high-pressure dilute-phase small-volume feeding device and control method

A technology of a feeding device and a control method, which is applied in the research field of efficient and clean utilization of coal, can solve the problems of decreased flow stability, complex flow pattern and high solid phase concentration, and achieves reduction of flow area, less investment and maintenance costs, and increased The effect of air intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

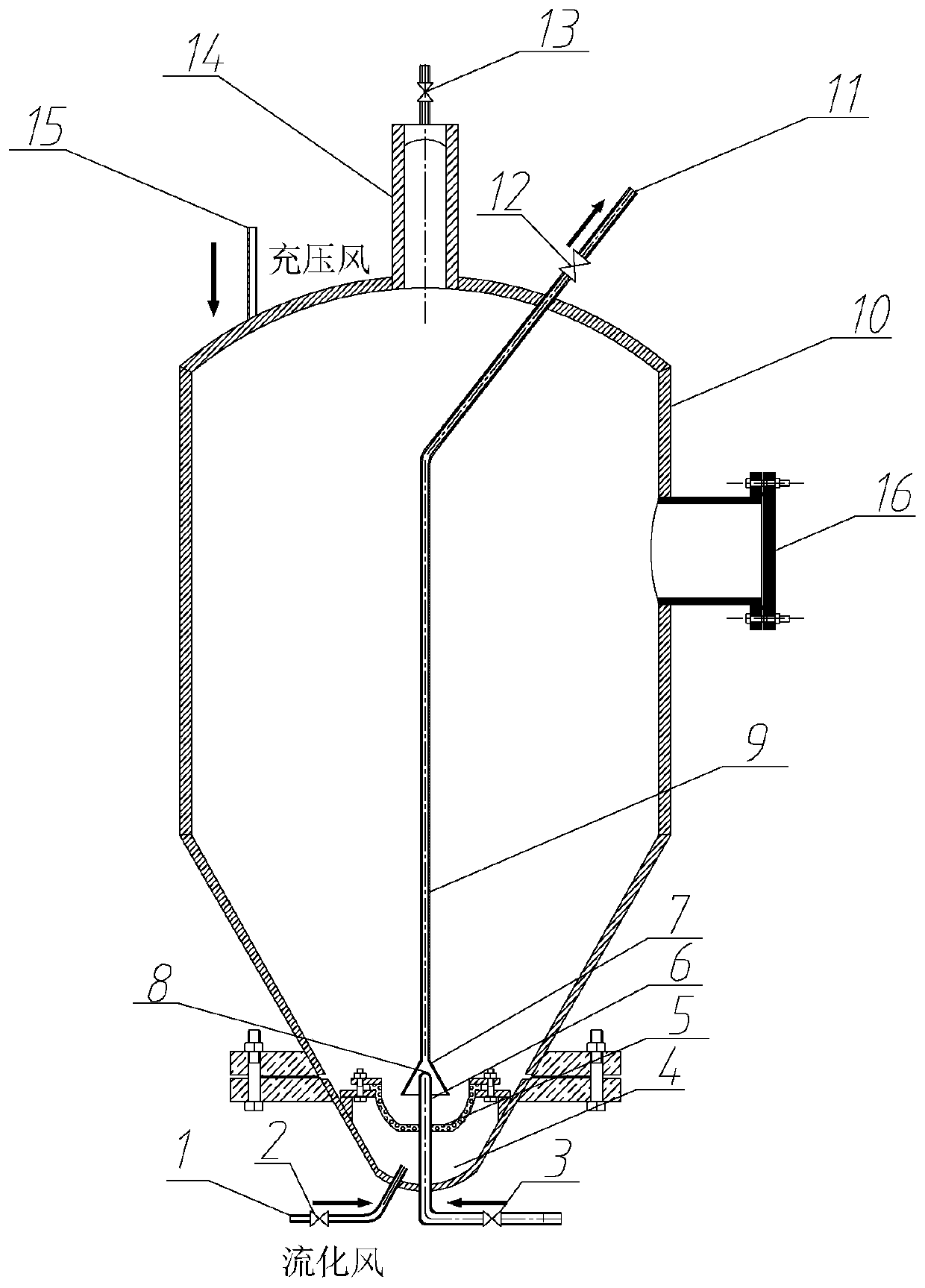

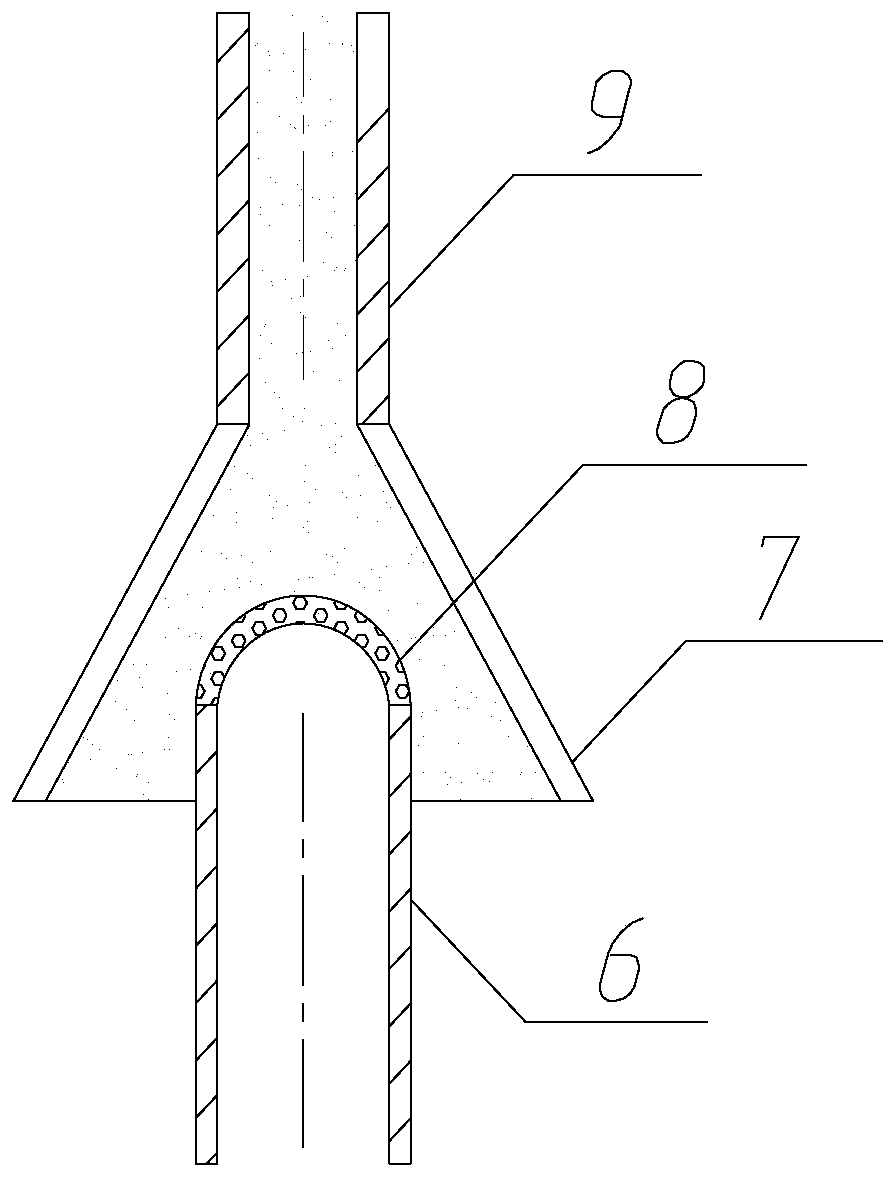

[0031] The high-pressure dilute-phase small-volume feeding device of the present invention includes a fluidization air pipe 1, a fluidization air control valve 2, an air supply pipe control valve 3, an air chamber 4, an air distribution plate 5, an air supply pipe 6, and a horn inlet. Material opening 7, porous ventilation plate 8, lifting section 9, conveying pipeline 11, discharge control valve 12, exhaust valve 13, bag dust collector 14, pressure air pipe 15, feeding port 16 and feeding tank. The top of the supplementary air pipe 6 is provided with a porous ventilation plate 8 and passes through the air distribution plate 5 to the bottom of the horn feed port 7 . The horn feed port 7 is arranged directly below the lifting section 9 , and the opening faces the fluidized air distribution plate 5 . The pipe diameter of the lifting section 9 is slightly smaller than the supplementary air pipe 6. Before starting work, add materials to the feeding tank through the feeding port 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com