Preparation method for strong-flavor clear ox bone soup

A strong-flavor, beef-bone technology, applied in the functions of food ingredients, food ultrasonic treatment, food heat treatment, etc., can solve the problems of large loss of nutrients and active substances, inability to meet quality and nutrition, poor flavor and stability, etc. To achieve the effect of increasing the flavor of bone broth, shortening processing time and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

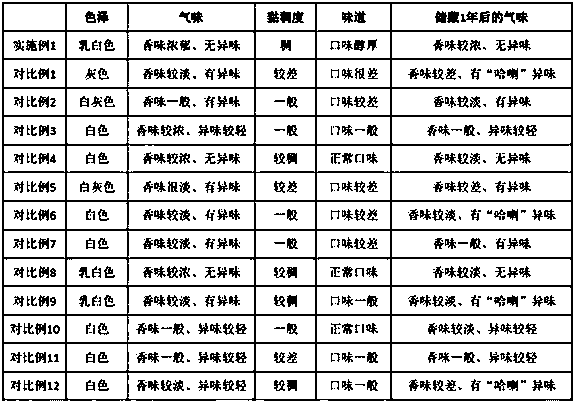

Examples

Embodiment 1

[0030] A kind of production technology of Luzhou-flavor beef bone white soup, comprises the following steps:

[0031] (1) Bovine bone crushing: 500 kg of fresh bovine bone is cut and crushed, and the diameter of the broken bone is 2-5 cm;

[0032] (2) Rinse: rinse with water;

[0033] (3) Warm soak: Add 0.03% sodium citrate and 0.02% sodium bisulfite to the rinsed bovine bone and water at a ratio of 1:1 for warm soak. When the water temperature reached 55 °C, under the conditions of ultrasonic power 5000 W and ultrasonic frequency 40 kHz, ultrasonic treatment was performed for 2 min every 5 min, for a total of 3 times, and the blood was poured out;

[0034] (4) Boiling: Put the soaked beef bones and water in a high-pressure cooking pot at a ratio of 1:1, add 0.6% eel, and cook for 3 hours at a temperature of 100-102°C. At the beginning of boiling, add 0.15% ethanol, and add 0.2% ethanol after 1 h. Add 0.6% reducing sugar after boiling for 0.5h, and the ratio of glucose, xyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com