Storage battery low-temperature charging and discharging method based on temperature compensation

A temperature compensation and storage battery technology, which is applied in the direction of secondary battery charging/discharging, lead-acid battery, secondary battery, etc., can solve the problems of shortened service life and achieve the effects of improving service life, avoiding water loss, and fully heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Taking a 12V 20AH battery pack as an example (here is a conventional 6-cell rated voltage 12V battery), the following steps are included:

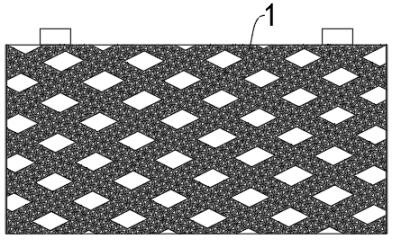

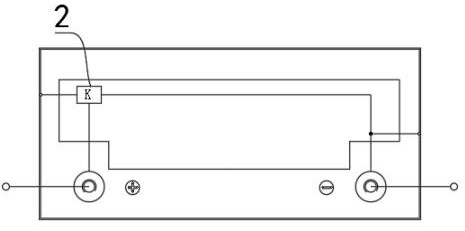

[0060] 1) Module heating: the ambient temperature is -15°C, the controller 22 receives the charging signal, and activates the temperature compensation device according to the detected ambient temperature, so that the resistance grid 1 is heated and the temperature rises by 35°C.

[0061] 2) Pre-charge judgment: the charging current is 2A=0.1CA*20AH, and the voltage of the battery pack can reach 2V*6=12V, then the battery pack has no faults and enters the segmented charging stage.

[0062] 3) Segmented charging:

[0063] The first stage: large current constant current charging stage, charging current 4.8A=0.24CA*20AH, constant current charging to battery voltage 14.4V=2.4V*6, or charging time reaches 2H, the program transfers to the second stage;

[0064] The second stage: large and medium current constant current charging stage, ch...

Embodiment 2

[0072] Take the 12V100AH battery pack as an example (here is a 12V battery with a rated voltage of 6 conventional cells), including the following steps:

[0073] 1) Module heating: the ambient temperature is -33°C, the controller 2 receives the charging signal, and activates the temperature compensation device according to the detected ambient temperature, so that the resistance grid 1 is heated, and the temperature rises by 56°C.

[0074] 2) Pre-charge judgment: the charging current is 10A=0.1CA*100AH, and the voltage of the battery pack can reach 2V*6=12V, then the battery pack has no faults and enters the segmented charging stage.

[0075] 3) Segmented charging:

[0076] The first stage: large current constant current charging stage, charging current 24A=0.24CA*100AH, constant current charging to battery voltage 14.4V=2.4V*6, or charging time reaches 3H, the program transfers to the second stage;

[0077] The second stage: large and medium current constant current chargi...

Embodiment 3

[0085] Take the 48V100AH battery pack as an example (here are four conventional 12V batteries with 6 cells of rated voltage), including the following steps:

[0086] 1) Module heating: the ambient temperature is -45°C, the controller 2 receives the charging signal, and activates the temperature compensation device according to the detected ambient temperature, so that the resistance grid 1 is heated, and the temperature rises by 62°C.

[0087] 2) Pre-charge judgment: the charging current is 10A=0.1CA*100AH, and the voltage of the battery pack can reach 2V*24=48V, then the battery pack has no faults and enters the segmented charging stage.

[0088] 3) Segmented charging:

[0089] The first stage: large current constant current charging stage, charging current 24A=0.24CA*100AH, constant current charging to battery voltage 57.6V=2.4V*24, or charging time reaches 3H, the program transfers to the second stage;

[0090] The second stage: large and medium current constant current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com