Gas outlet method of converter in anhydrous hydrofluoric acid production line

An anhydrous hydrofluoric acid, production line technology, applied in separation methods, chemical instruments and methods, perfluorocarbon/hydrofluorocarbon capture, etc., can solve problems affecting stable production operation, casualties, leakage, etc., Achieve the effect of buffering corrosion, prolonging service life and reducing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

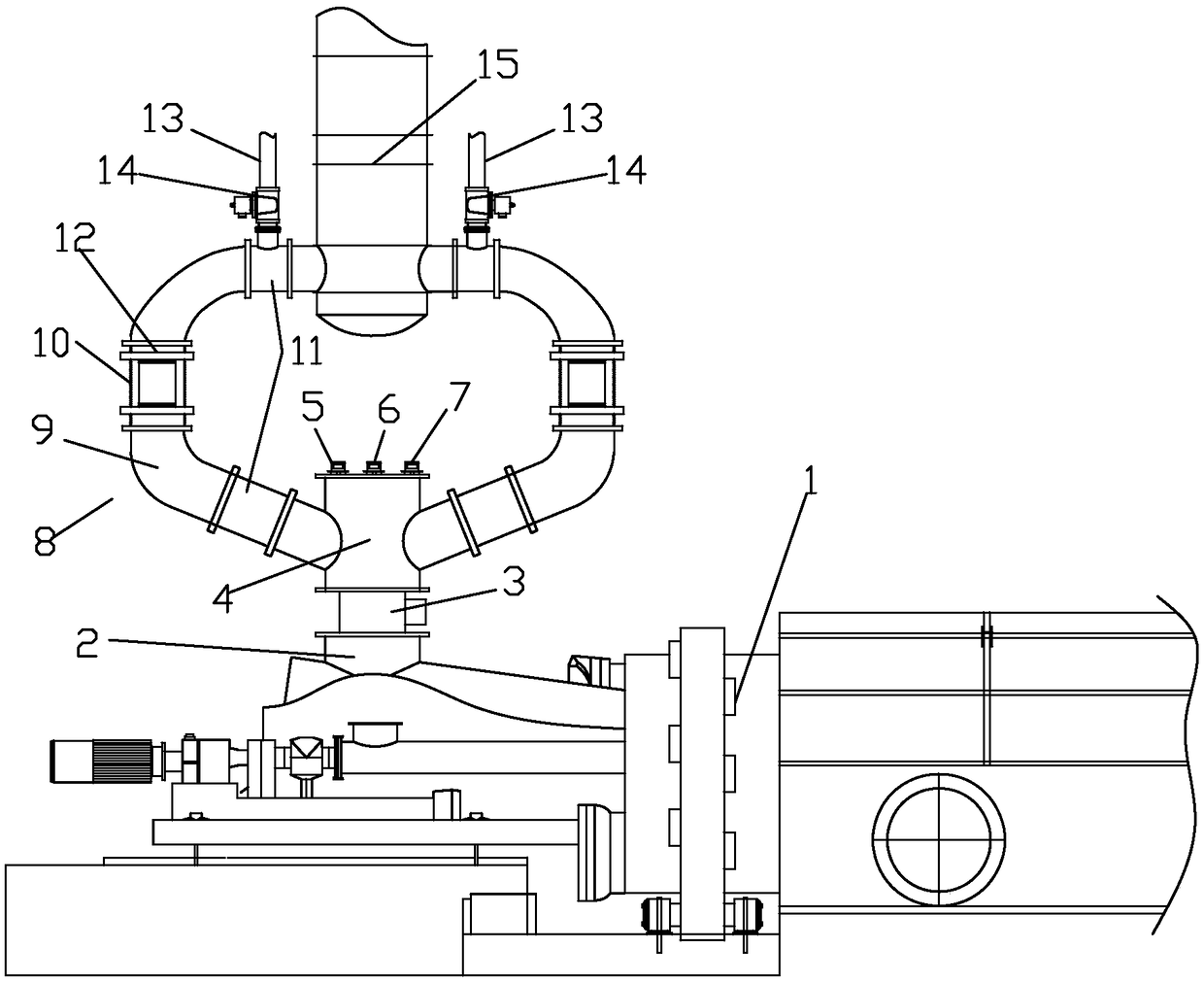

[0032] Such as Figure 1 to Figure 4 Shown, a kind of anhydrous hydrofluoric acid production line converter gas outlet method comprises the steps:

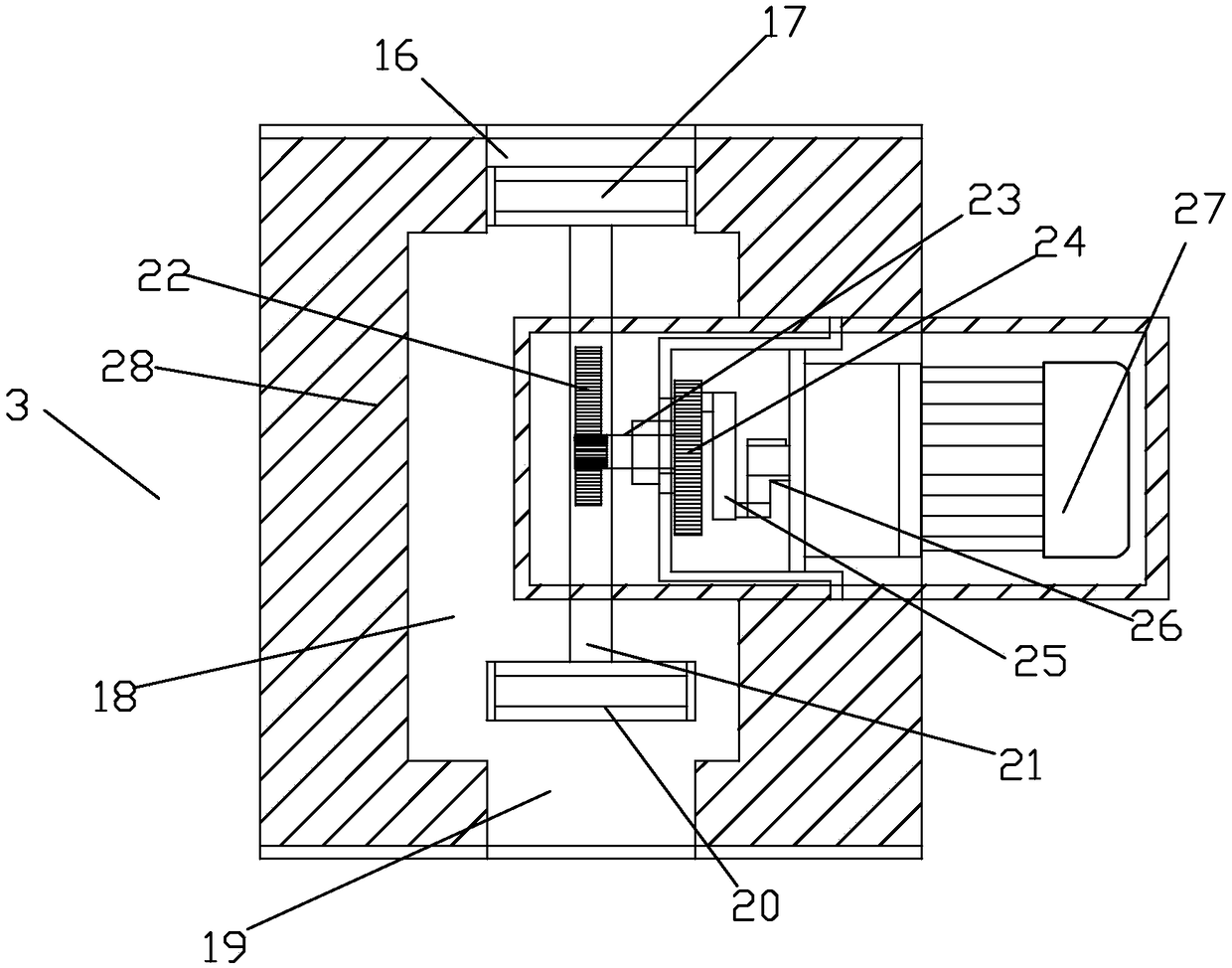

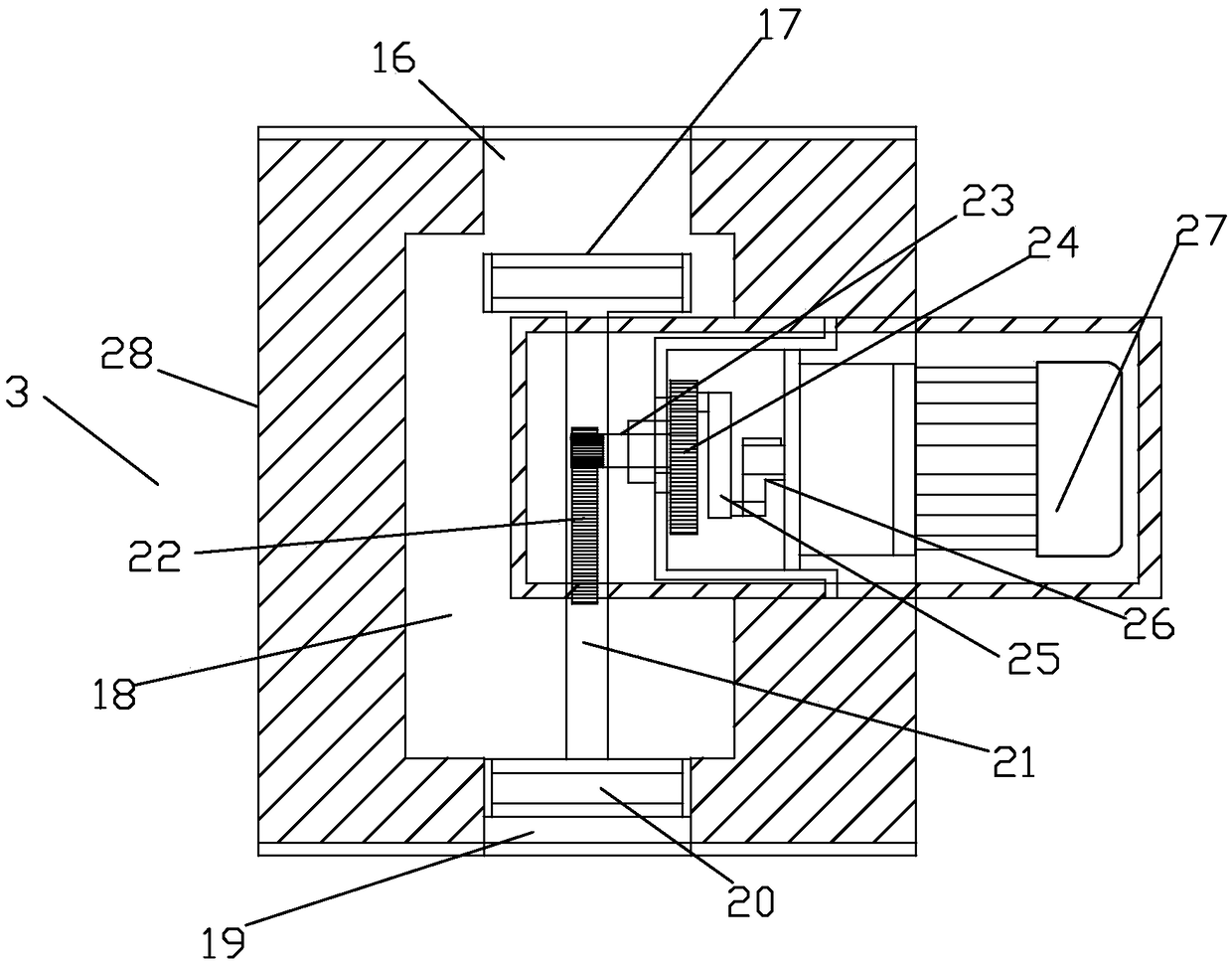

[0033] (1) Assembly of intake buffer 3:

[0034] a. Before assembling the intake buffer 3, firstly take the various parts of the intake buffer 3, including the casing 28, the motor 27, the driving gear shaft 23, the steel rod 21, the shoulder 26, the connecting plate 25, and the reciprocating gear 24. The inlet plug 20 and the outlet plug 17; the upper end of the casing 28 is provided with an outlet 16, the lower end of the casing 28 is provided with an inlet 19, and a gas flow channel 18 is formed in the casing 28; on the surface of each component and the casing 28 The inner surface is painted with anti-corrosion coating, and the anti-corrosion coating is selected from one of modified phenolic resin, barite, and nano-chromium powder. These anti-corrosion materials are dense and stable, and have good resistance to strong acids, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com