Pot calciner thermoregulation control device and method

A pot calcining furnace and control device technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of large temperature error, low degree of automation, difficult to guarantee product quality, etc., to improve the working environment, improve the degree of automation, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in a non-limiting manner below in conjunction with the accompanying drawings.

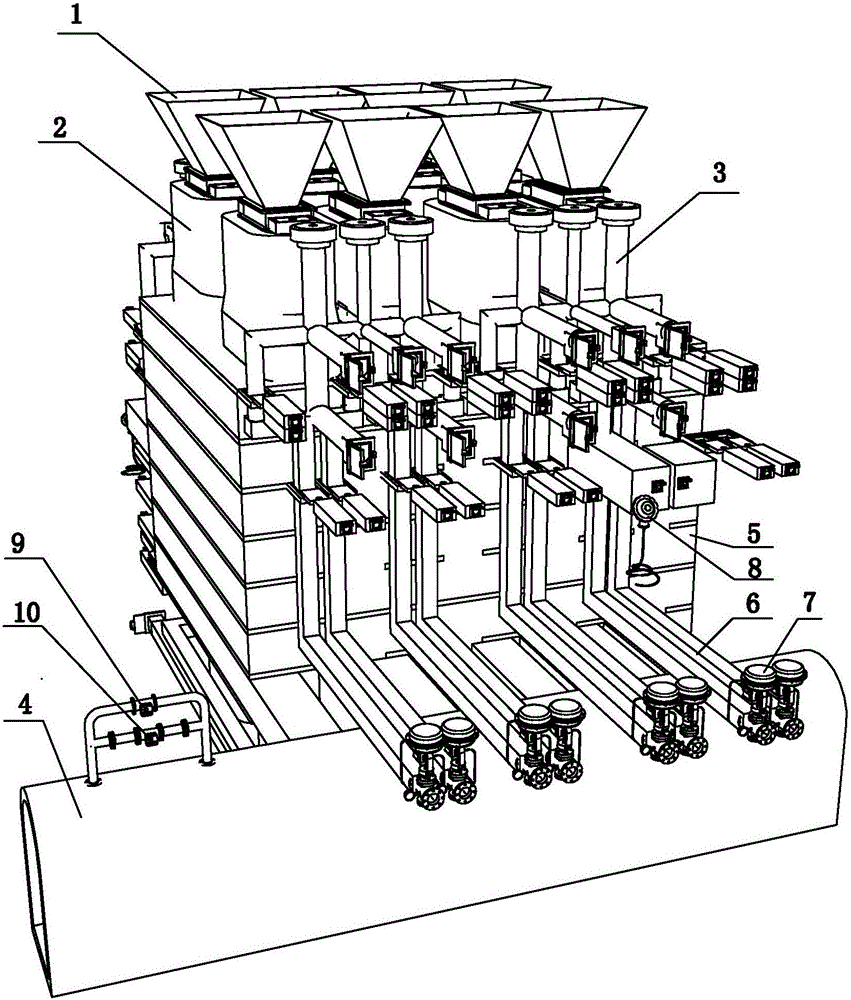

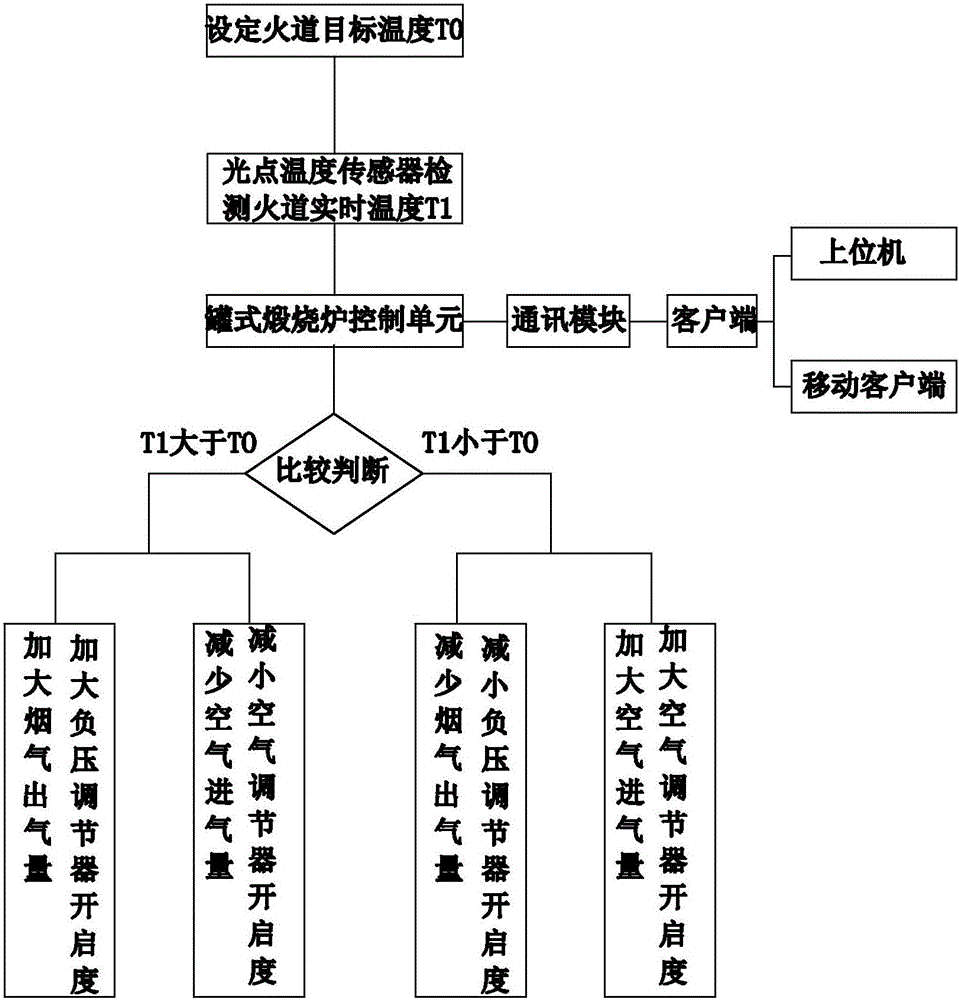

[0025] like figure 1 As shown, the pot calciner in the present invention comprises a tank body 2, the top of the tank body 2 is provided with a hopper 1, and the outside of the tank body 2 is provided with a volatile matter passage 3, a fire passage 5, and an air passage communicated with the fire passage 5 6, the collection flue 4 that communicates with the bottom fire path. The tank-type calciner temperature control device of the present invention comprises: a photoelectric temperature sensor 8 installed on the fire path 5 of the tank-type calciner, an air conditioner 7 installed on the inlet of the air channel 6 of the tank-type The negative pressure regulator 10 at the outlet of the collection flue 4 of the calciner, the flue gas pressure gauge 9 is also installed on the collection flue 4, the photoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com