Control system for express bag sealing and gluing machine

A technology of control system and glue machine, which is applied in the field of packaging bags, can solve the problems of reduced operating speed of the whole machine, many manual adjustment steps, and increased failure rate, so as to achieve stable operation, reduce manual debugging costs, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

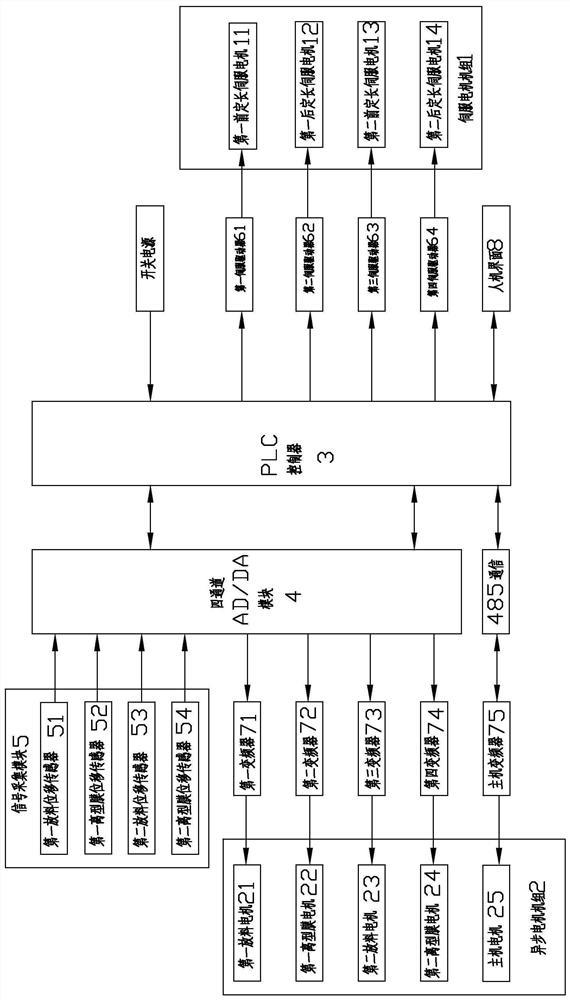

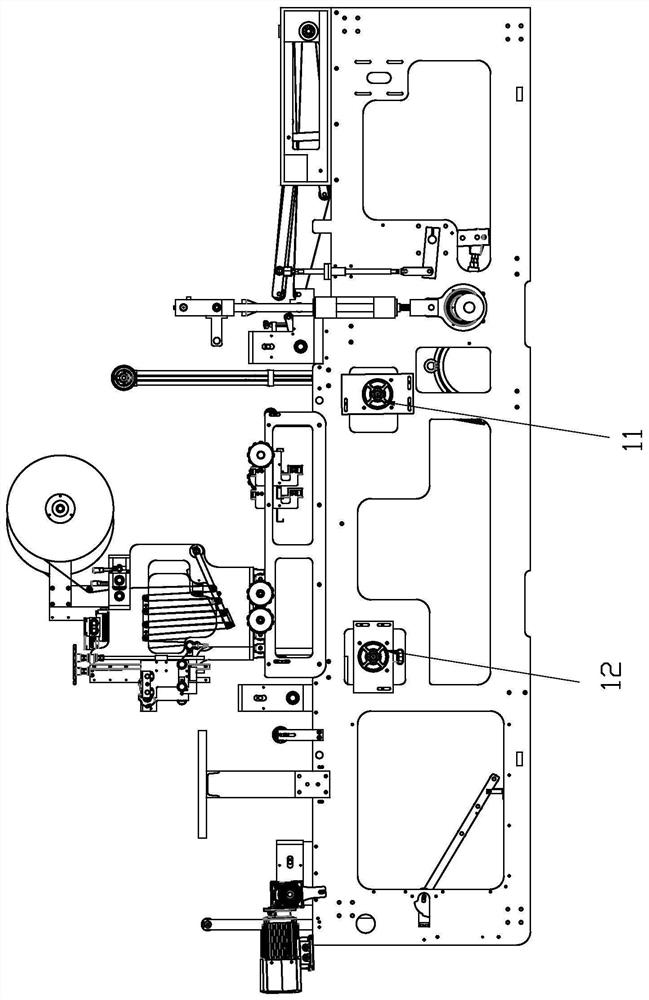

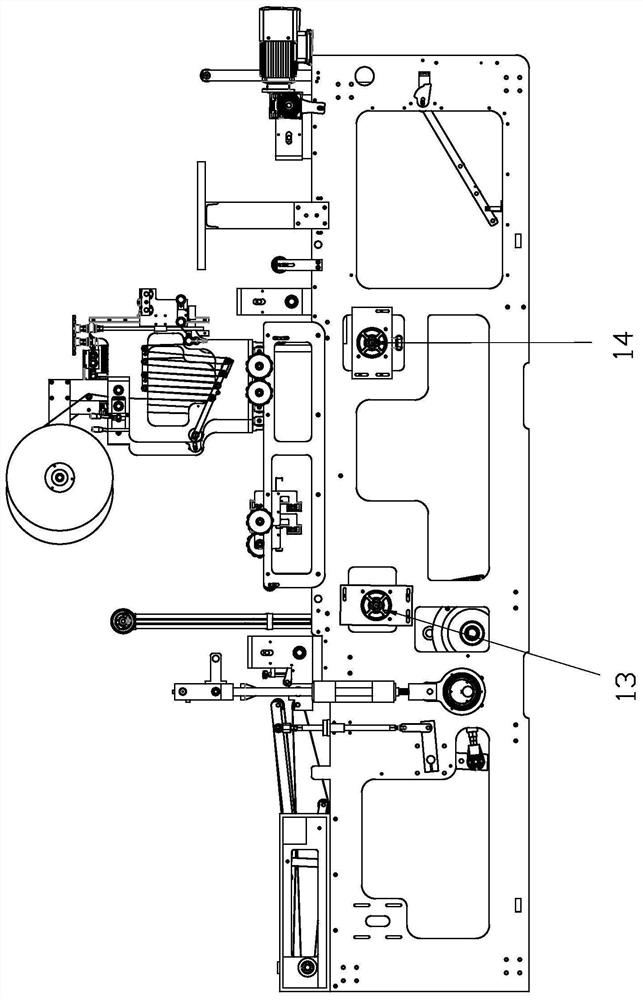

[0022] Such as Figure 1-Figure 4 As shown, the control system of the present invention includes a PLC controller, an AD / DA module, a servo motor unit, an asynchronous motor unit and a signal acquisition module. Automatic control, 4 sets of servo motors carry out precise length-determined feeding according to the set length, 4 sets of three-phase AC asynchronous motors realize full-closed loop control according to the host speed and displacement signal position, realize automatic linkage operation of 9 sets of motors, and have stable operation , low failure rate, and the characteristics of linkage adjustment of operating speed, and the system can link 9 motors to automatically modify the corresponding parameters by outputting the express bag specifications that need to be processed on the PLC controller, improving work efficiency and reducing manual debugging costs.

[0023] In this embodiment, the PLC controller is a programmable controller dedicated to CITIC Electronics. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com