A power plant intelligent chemical water condition control system and method

A control system and control method technology, applied in general control system, control/regulation system, control/manipulation system, etc., can solve the problem that operators cannot choose the water treatment method, affect safety and economy, scale and salt accumulation high speed problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and specific examples.

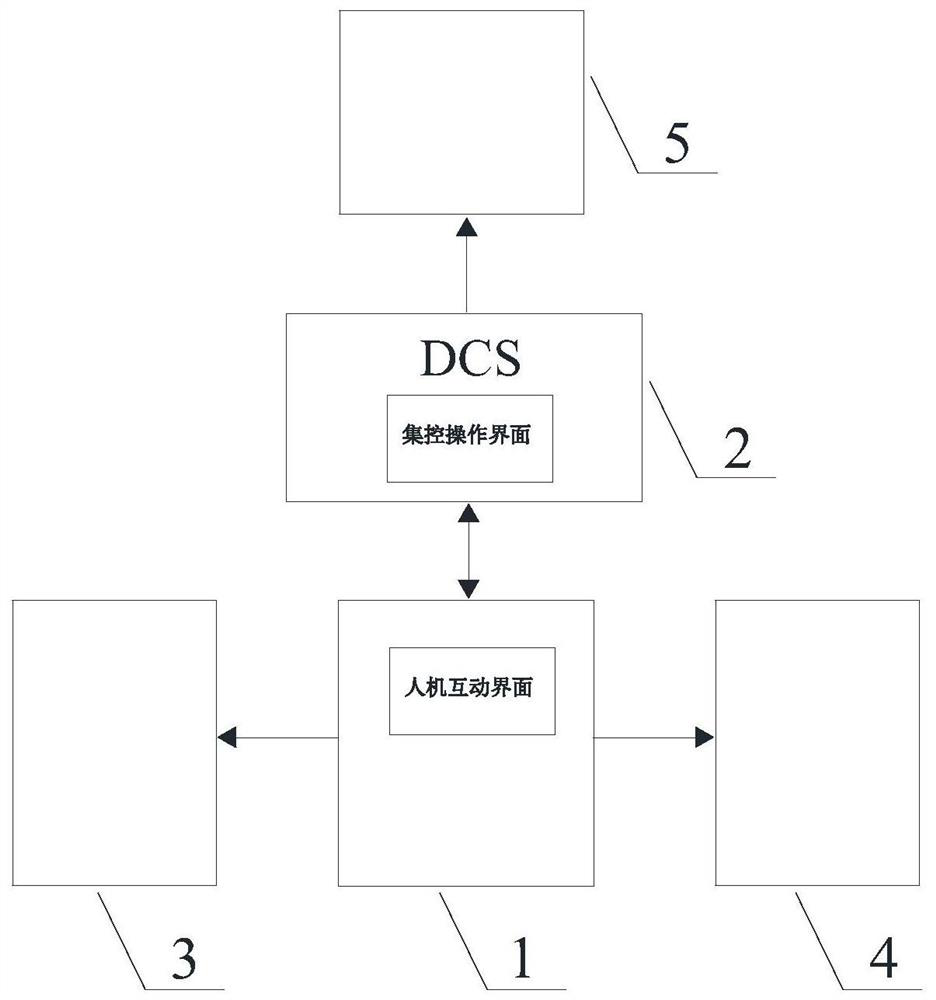

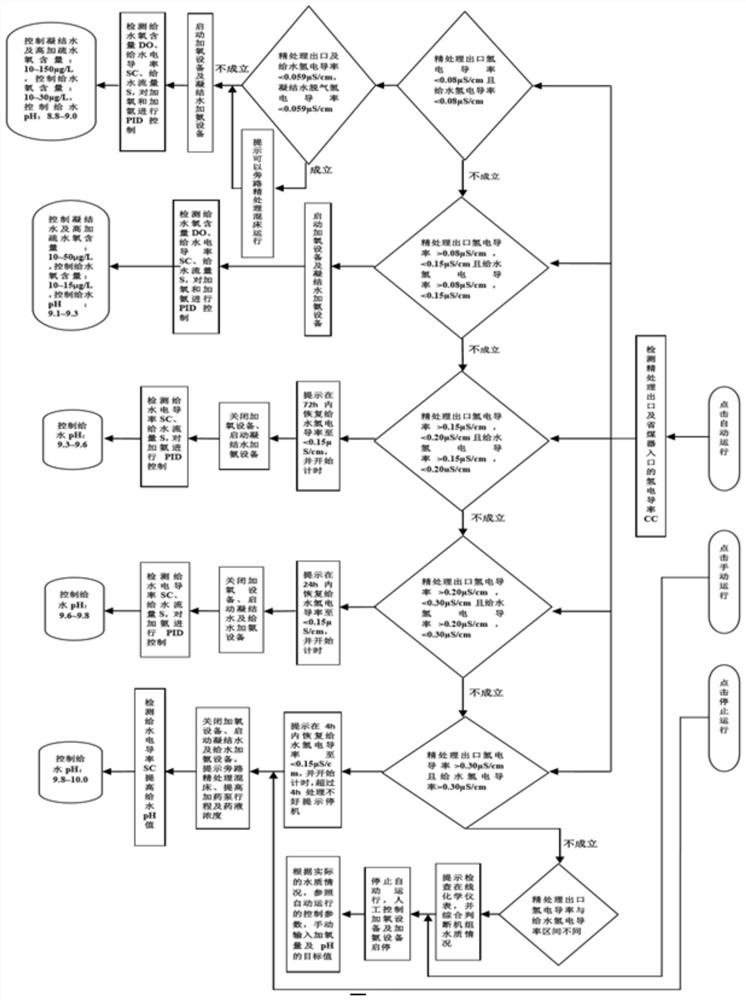

[0028] Such as figure 1 and figure 2As shown, when the automatic operation is clicked, the intelligent chemical water condition control device 1 continuously collects the hydrogen conductivity signals from the condensate polishing outlet of the DCS control system 2 and the inlet of the economizer. When the hydrogen conductivity of the condensate polishing outlet 0.08μS / cm, 0.08μS / cm, 0.15μS / cm, 0.15μS / cm, 0.20 When μS / cm, 0.20μS / cm, 0.30 When μS / cm and the hydrogen conductivity of the feed water is >0.30 μS / cm, it will prompt to restore the hydrogen conductivity of the feed water to <0.15 μS / cm within 4 hours, and start timing. If the treatment is not good after 4 hours, it will prompt to stop. Turn off the oxygenation equipment 3. Start the condensate water and feedwater ammonia addition equipment, prompt the bypa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com