Composite for improving interfacial effect of photoresist dry film and barrier and preparation and usage method thereof

A photoresist and composition technology, applied in the manufacture of discharge tubes/lamps, the manufacture of ships or lead wires, the manufacture of cold cathodes, etc., can solve the problem that the surface layer of the barrier cannot be bonded, the interface effect is poor, and the barrier collapse and other problems, to achieve the effect of improving interface effect, small surface tension and reducing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

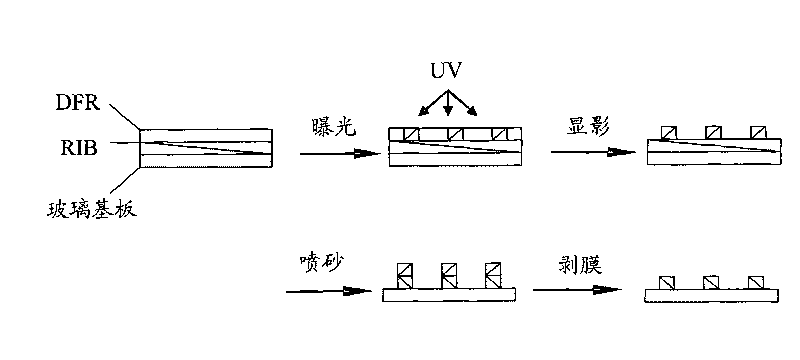

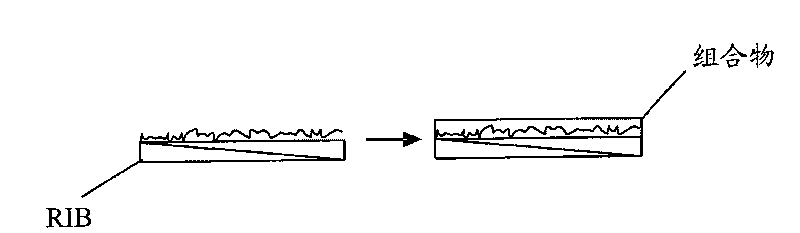

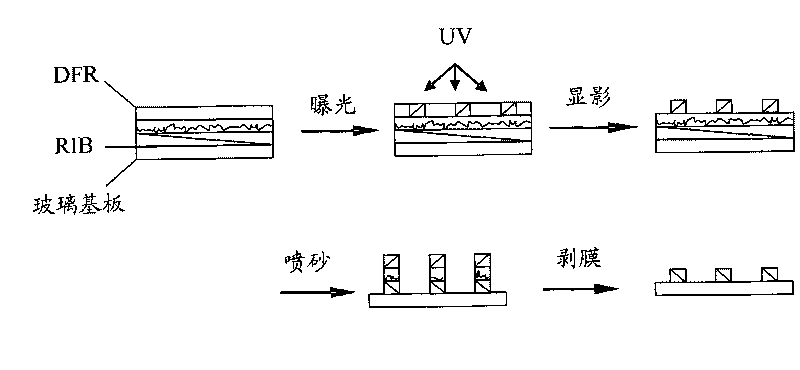

[0036] Mix 200 g of diethylene glycol methyl butyl ether acetate, 100 g of butyl methacrylate, and 10 g of ethyl cellulose, and stir until completely dissolved. Add 20g of glass powder, wherein, based on the total weight of the glass powder, the mass ratio of the glass powder composition is: 0.5wt% SiO 2 , 50wt% ZnO, 35wt% B 2 o 3 , 0.2wt% Na 2 O, 14wt% BaO, and 0.3wt% K 2 O. Then, 100 g of 2-hydroxyethyl methacrylate, 5 g of dibutyl phthalate, and 5 g of isopropanol were added, followed by stirring for 5 hours. Continue to stir until the bubbles disappear, set aside. Lead-free barrier ribs are then fabricated using techniques known to those skilled in the art. Brush the above prepared composition evenly on the barrier and dry it. The DFR film is pasted on the barrier layer, and the DFR film pattern is produced through the traditional exposure and development process. Sand blasting etching is used to etch the pattern, and the composition of the present invention and ba...

Embodiment 2

[0038] Mix 200 g of diethylene glycol methyl butyl ether acetate, 100 g of butyl methacrylate, and 10 g of ethyl cellulose, and stir until completely dissolved. Add glass powder 35g, wherein, based on the total weight of the glass powder, the mass ratio of the glass powder composition is: 3wt% SiO 2 , 40wt% ZnO, 35wt% B 2 o 3 , 0.2wt% Na 2 O, and 21.8 wt% BaO. 130 g of methylol acrylate, 5 g of dibutyl phthalate, and 5 g of isopropanol were added, and stirred for 5 hours. Stirring was continued until the bubbles disappeared to obtain the composition of Example 2. Then, barrier ribs were fabricated by the same method as in Example 1 using the composition prepared above.

Embodiment 3

[0040] Mix 200 g of diethylene glycol methyl butyl ether acetate, 100 g of butyl methacrylate, and 10 g of ethyl cellulose, and stir until completely dissolved. Add glass powder 10g, wherein, based on the total weight of the glass powder, the mass ratio of the glass powder composition is: 5wt% SiO 2 , 30wt% ZnO, 45wt% B 2 o 3 , 5wt% Na 2 O, 12wt% BaO, and 3wt% K 2 O. 180 g of 2-hydroxyethyl methacrylate, 5 g of dibutyl phthalate, and 5 g of isobutanol were added, and stirred for 5 hours. Stirring was continued until the bubbles disappeared to obtain the composition of Example 3. Then, barrier ribs were fabricated by the same method as in Example 1 using the composition prepared above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com