Variable stiffness self-healing material containing metal-mercapto coordination bond and its preparation and application

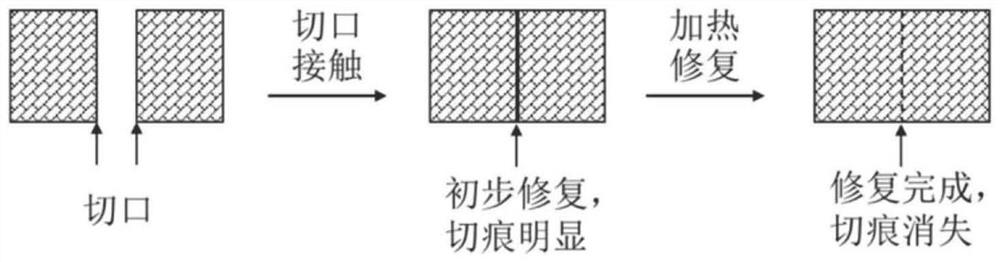

A self-healing material and variable stiffness technology, applied in additive processing, adhesives, etc., can solve the problems of water vapor sensitivity, complicated synthesis steps, limited practical application fields, etc., and achieve simple steps, excellent flexibility, and good self-healing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

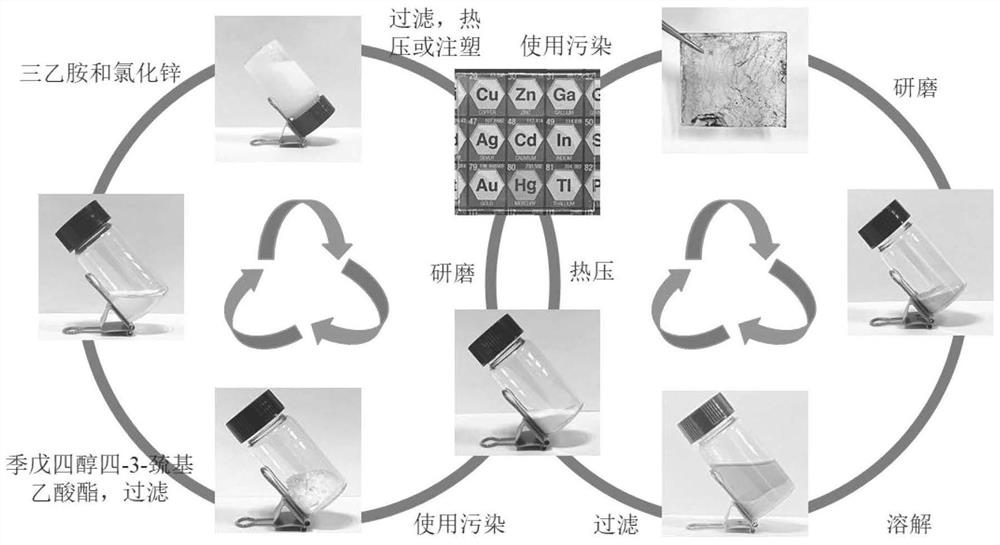

[0069] A variable stiffness self-healing material containing a metal-mercapto coordination bond and a preparation method thereof:

[0070] 50.00g of pentaerythritol tetra-3-mercaptopropionate was added to the flask, then 100mL of dichloromethane was added as a solvent, the reaction temperature was controlled to 25°C, the stirring speed was 100r / min, and the reaction was carried out for 30min to obtain a compound solution with a terminal mercapto group;

[0071] 8.28g of triethylamine was added to the above-mentioned mercapto-terminated compound solution, and the reaction temperature was controlled at 25°C and the stirring speed was 200r / min under sealed conditions, and the reaction was carried out for 4h;

[0072] Add 0.30g of pentaerythritol triacrylate to the above mixing system, control the reaction temperature under sealed conditions at 25°C, stir at 200r / min, and react for 6h;

[0073] Preparation of metal zinc salt solution: take 13.79g of zinc chloride, add 15mL of meth...

Embodiment 2

[0078] A variable stiffness self-healing material containing a metal-mercapto coordination bond and a preparation method thereof:

[0079] 80.00g of trimethylolpropane tris(2-mercaptoacetate) and 19.83g of mercapto-terminated liquid polysulfide resin with a relative molecular mass of 1000 were added to the flask, and then 100mL of dichloromethane was added as a solvent, and the reaction temperature was controlled at 25°C, The stirring speed was 150r / min, and the reaction was carried out for 30min to obtain the compound solution of the terminal mercapto group;

[0080] 20.00 g of triethanolamine was added to the above-mentioned mercapto-terminated compound solution, and the reaction temperature was controlled to be 25° C. and the stirring speed was 250 r / min under sealed conditions, and the reaction was carried out for 4 hours;

[0081] 30.00g of pentaerythritol triacrylate was added to the above mixed system, and the reaction temperature was controlled to be 25°C under sealed ...

Embodiment 3

[0088] 20.00g of 2,7-naphthyldithiol and 4.16g of mercapto-terminated liquid polysulfide resin with a relative molecular mass of 4000 were added to the flask, and then 100mL of tetrahydrofuran was added as a solvent. , to obtain the compound solution of the terminal thiol group;

[0089] 2.84g of N,N-dimethylbenzylamine was added to the above-mentioned mercapto-terminated compound solution, and the reaction temperature was controlled at 25°C and the stirring speed was 250r / min under sealed conditions, and the reaction was carried out for 4h;

[0090] To the above mixed system, 7.72 g of triphenylmethane triisocyanate was added, and the reaction temperature was controlled to be 25° C. under sealed conditions, and the stirring speed was 300 r / min, and the reaction was carried out for 6 hours;

[0091] Preparation of metal zinc salt solution: take 7.12g of zinc sulfate, add 10mL of methanol as a solvent, and carry out ultrasonic treatment for 1h at 25°C and ultrasonic power of 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

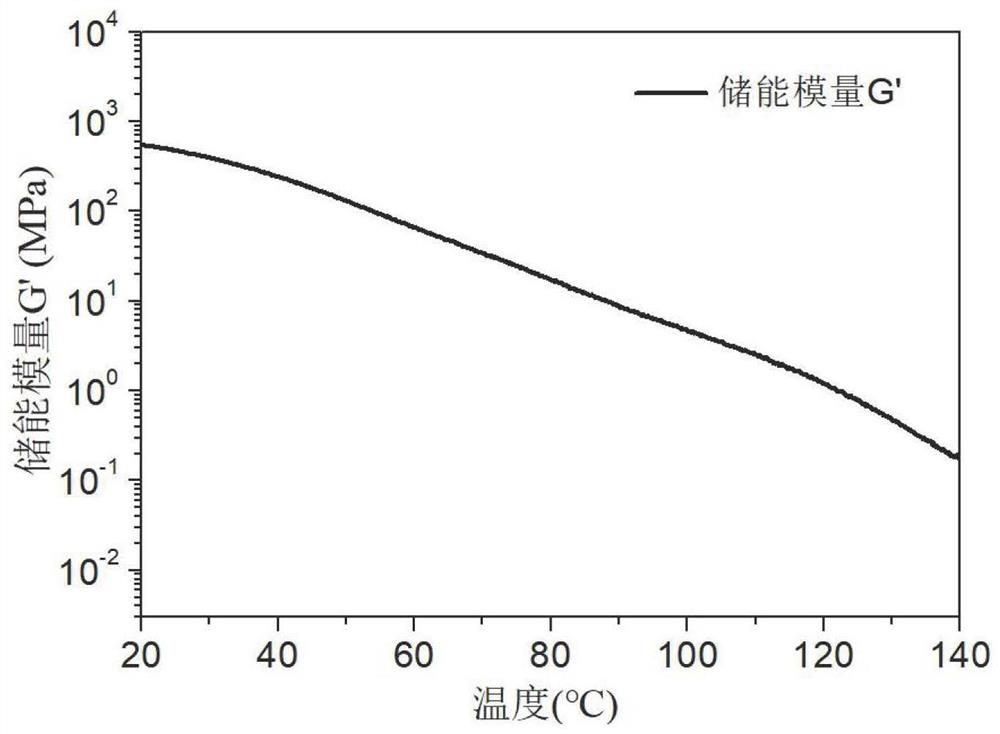

| storage modulus | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com