Regenerant for aged asphalt and preparation method thereof

A technology of aging asphalt and regenerant, which is applied to building components, plastic/resin/wax insulators, organic insulators, etc. It can solve the problems of poor storage stability, low yield, high void ratio, etc., and achieve high strength and bonding strength, High corrosion resistance, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

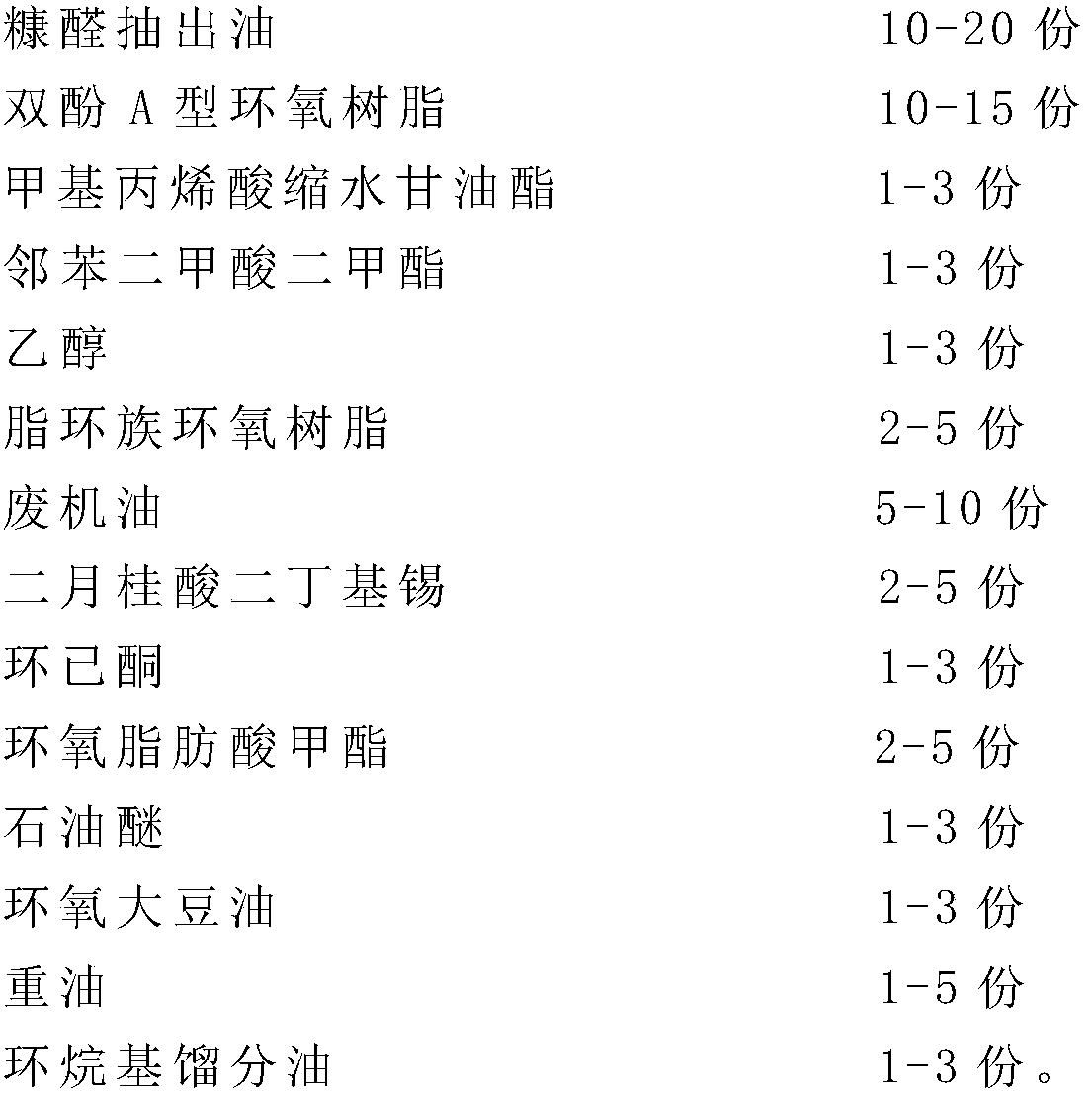

[0037] A regeneration agent suitable for aged asphalt, consisting of the following components in parts by weight:

[0038]

[0039]

Embodiment 2

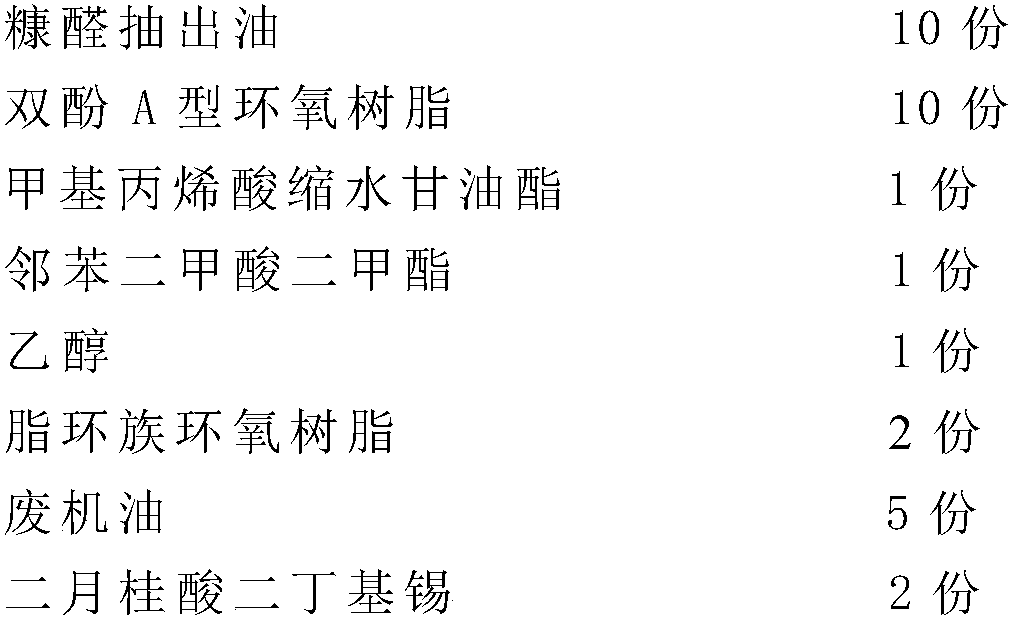

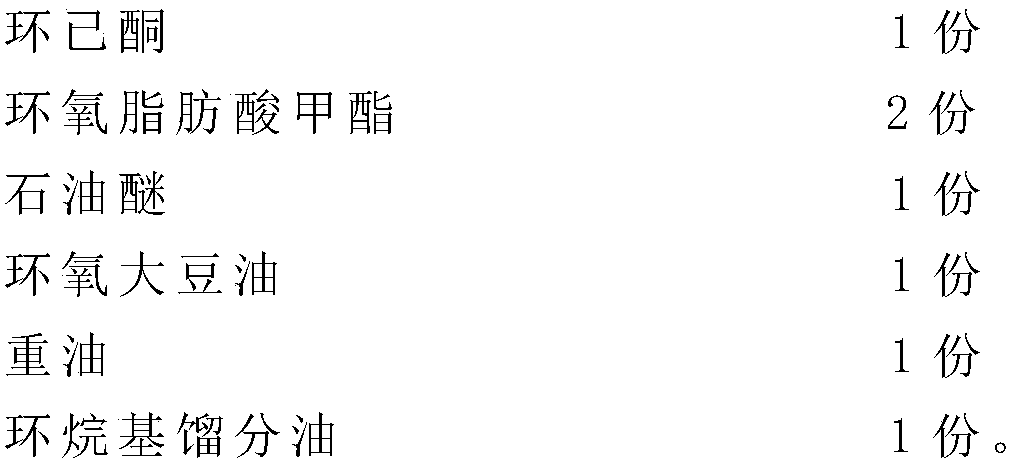

[0041] A regeneration agent suitable for aged asphalt, consisting of the following components in parts by weight:

[0042]

[0043] "16 parts of furfural extract oil, 12 parts of bisphenol A type epoxy resin, 2 parts of glycidyl methacrylate, 2 parts of dimethyl phthalate, 2 parts of ethanol, alicyclic epoxy resin 3 parts of resin, 9 parts of waste engine oil, 3 parts of dibutyltin dilaurate, 2 parts of cyclohexanone, 3 parts of epoxy fatty acid methyl ester, 2 parts of petroleum ether, 2 parts of epoxy soybean oil, 3 parts of heavy oil and 2 parts of naphthenic distillate oil", the asphalt rejuvenator composed of this specific ratio can effectively highlight high temperature performance, low temperature crack resistance, aging resistance and weather resistance, and the characteristics are relatively balanced. achieve an optimal balance.

[0044] The following table 1 is the performance comparison between the regenerant of the present application and the asphalt pavement m...

Embodiment 3

[0050] A regeneration agent suitable for aged asphalt, consisting of the following components in parts by weight:

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com