Long-acting self-repairing super-hydrophobic ceramic coating as well as preparation method and application thereof

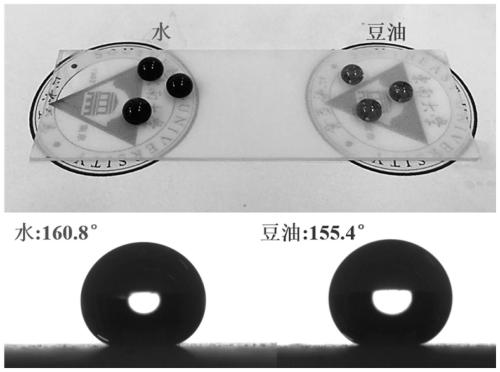

A ceramic coating and super-hydrophobic technology, applied in the direction of coating, can solve the problem of poor wear resistance of inorganic nano-particle-based super-hydrophobic coatings, and achieve the effect of improving the hydrophobicity of the coating, solving the poor flexibility and improving the wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

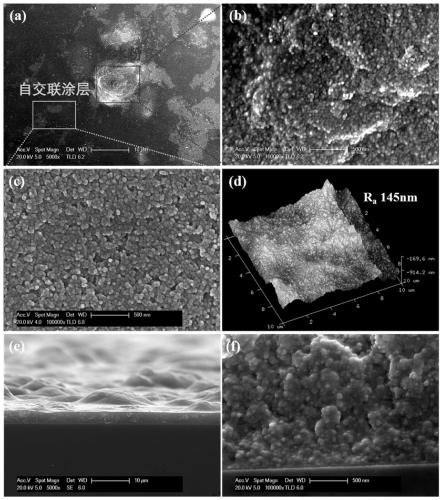

[0029] A preparation method of a long-acting self-repairing superhydrophobic ceramic coating. In this embodiment, the inorganic nanoparticles are titanium dioxide, the siloxane monomer is methyltrimethoxysilane, the volatile organic solution is acetone, and the pH adjusting solution is hydrochloric acid Solution, the preparation steps are as follows:

[0030] (1) Disperse 10 parts by mass of inorganic nanoparticles, 8 parts by mass of acidic pH adjusting solution, 1 part by mass of tetraethyl orthosilicate, and 4 parts by mass of siloxane monomer in 80 parts by mass of volatile organic solvent, and continuously stir 12 h, the ceramic coating was prepared;

[0031] (2) Disperse 8 parts by mass of acidic nano silica sol with a particle size of 135-200nm, 6 parts by mass of 35wt.% ammonia water, 12 parts by mass of deionized water, 0.5 parts by mass of tetraethyl orthosilicate, and 0.5 parts by mass of hydrophobic treatment agent In 80 parts by mass of volatile organic solvents,...

Embodiment 2

[0038] A method for preparing a self-repairing superhydrophobic ceramic coating. In this embodiment, the inorganic nanoparticles are titanium dioxide, the siloxane monomer is methyltrimethoxysilane, the volatile organic solution is acetone, and the pH adjusting solution is hydrochloric acid solution. The preparation steps are as follows:

[0039] (1) Disperse 20 parts by mass of inorganic nanoparticles, 16 parts by mass of acidic pH adjusting solution, 2 parts by mass of tetraethyl orthosilicate, and 8 parts by mass of siloxane monomer in 60 parts by mass of volatile organic solvent, and continuously stir 24 h, the ceramic coating was prepared;

[0040] (2) 15 parts by mass of acidic nano-silica sol with a particle diameter of 35-135nm, 10 parts by mass of 35wt.% ammonia water, 16 parts by mass of deionized water, 1 part by mass of tetraethyl orthosilicate, and 2 parts by mass of hydrophobic treatment agent Dispersed in 60 parts by mass of volatile organic solvents, and conti...

Embodiment 3

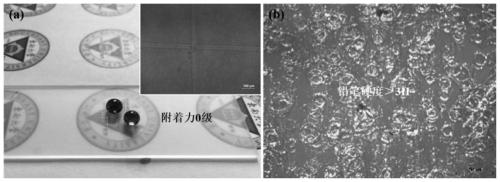

[0047] image 3 Be the self-healing superhydrophobic ceramic coating mechanical property in embodiment 2. According to the ISO 2409 standard, the cross-cut adhesion test is carried out. The adhesion strength of the tape used on the coating is not less than (10±1) N / 25mm. It can be found that the coating has no peeling off and 100% adhesion, which meets the standard. level 0. The pencil hardness test found that after the coating was scratched by a 3H pencil, the coating was not damaged and was still intact and dense, which proved that the coating hardness was > 3H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com