High-resilience polyurethane/organic silicon thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and polyurethane technology, applied in the field of dynamic vulcanization thermoplastic elastomer, can solve the problems of being unsuitable for widespread industrialization, increasing preparation steps and equipment, unfavorable continuous industrial production, etc., and achieving easy control of crosslinking degree and more vulcanization reaction Excellent stability and prolonged vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] First, the present invention provides a method for preparing a high resilience polyurethane / organic silicon thermoplastic elastomer, comprising the steps of:

[0037] S1 rubber and plastic blend

[0038] Blending thermoplastic polyurethane, vinyl silicone rubber, compatibilizer, and reinforcing filler, and pre-mixing in an internal mixer, cooling down after mixing, adding a cross-linking agent and continuing mixing to obtain a rubber-plastic blend;

[0039] S2 pre-crosslinked

[0040] Add the rubber-plastic blend in S1 into a twin-screw extruder, add a prepolymerization catalyst to the front of the twin-screw extruder for pre-vulcanization, and shear and disperse to obtain a pre-vulcanized cross-linked product;

[0041] S3 dynamic vulcanization

[0042] When the pre-vulcanized cross-linked product in S2 passes through the middle section of the screw in the twin-screw extruder, a dynamic vulcanization catalyst is added, sheared and dispersed, and then granulated to obt...

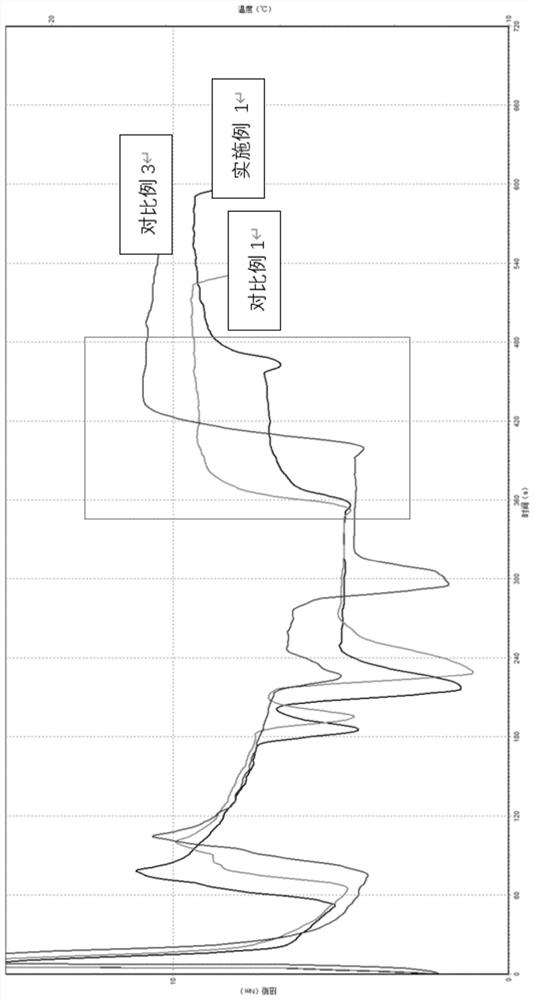

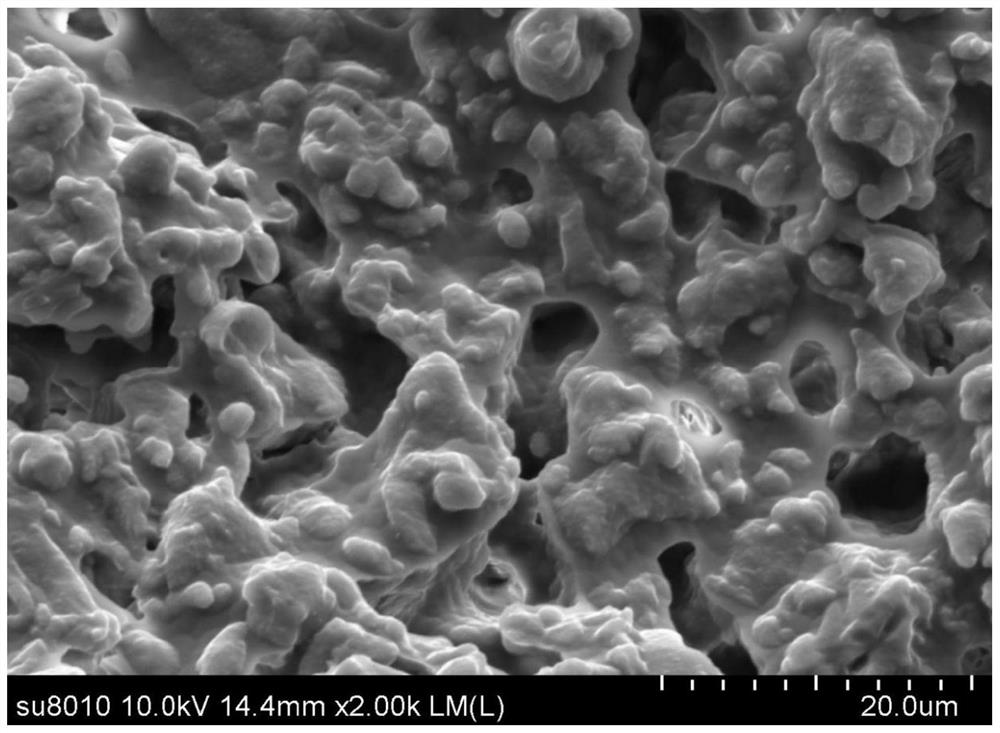

Embodiment 1

[0087] A preparation method of high resilience polyurethane / organic silicon thermoplastic elastomer, comprising the steps of: 100 parts of TPU after drying, 100 parts of methyl vinyl silicone rubber 1 and 10 parts of reactive compatibilizer 1, 10 parts Reinforcing filler 1, 3 parts of cross-linking agent 1 are mixed uniformly in the mixer of the torque rheometer at 180°C and 120rpm, and then 0.8 parts of pre-polymerization catalyst 1 are added first, under the shearing action of the mixing device, and then at temperature Mix at 180°C and 120rpm for about 1min, then add 2.5 parts of dynamic vulcanization catalyst 1, and continue dynamic vulcanization to obtain high resilience polyurethane / silicon thermoplastic elastomer.

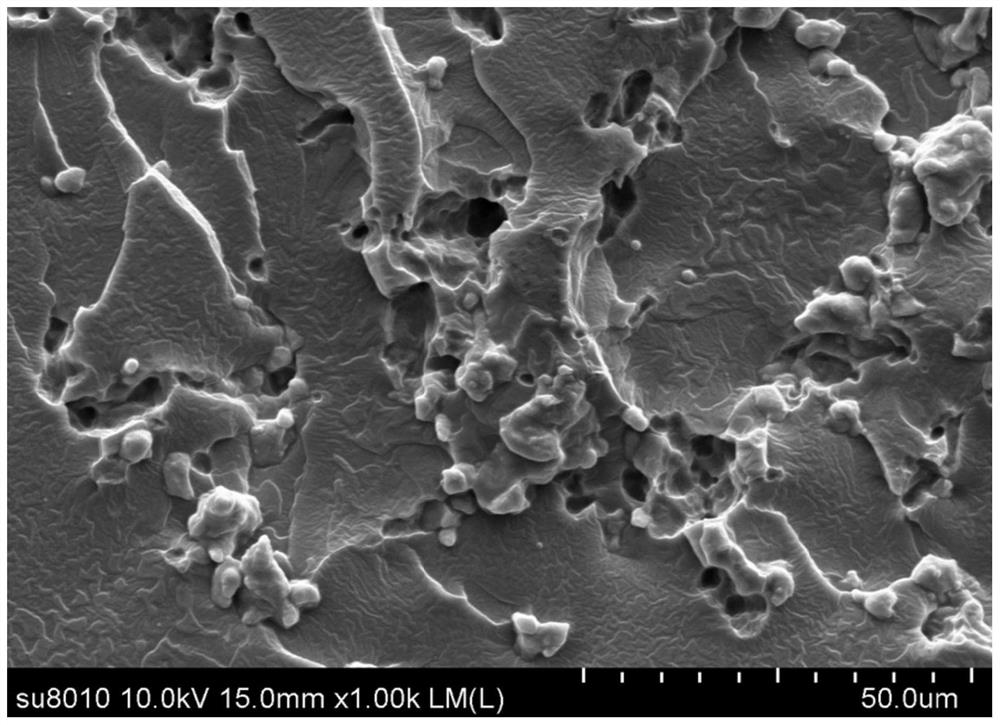

Embodiment 2

[0089] A preparation method of high resilience polyurethane / organic silicon thermoplastic elastomer, comprising the steps of: 100 parts of TPU after drying, 100 parts of methyl vinyl silicone rubber 2 and 15 parts of reactive compatibilizer 1, 18 parts Reinforcing filler 2 and 2 parts of crosslinking agent 2 are mixed evenly in the mixer of the torque rheometer at 190 ° C and 100 rpm, and then 0.5 parts of pre-polymerization catalyst 1 are added first. ℃, 120rpm, first mix for about 1min, then add 3 parts of dynamic vulcanization catalyst 1, and continue dynamic vulcanization to obtain high resilience polyurethane / silicon thermoplastic elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com