Stone oil well drilling sullage continuous processing technique

A technology of oil drilling and treatment process, applied in the direction of water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of reducing the color of sewage and other pollutants, and discontinuous treatment of sewage , Difficult combination between treatments and other problems, to achieve harmless, fast and efficient oxidation, and solve the effect of difficult combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

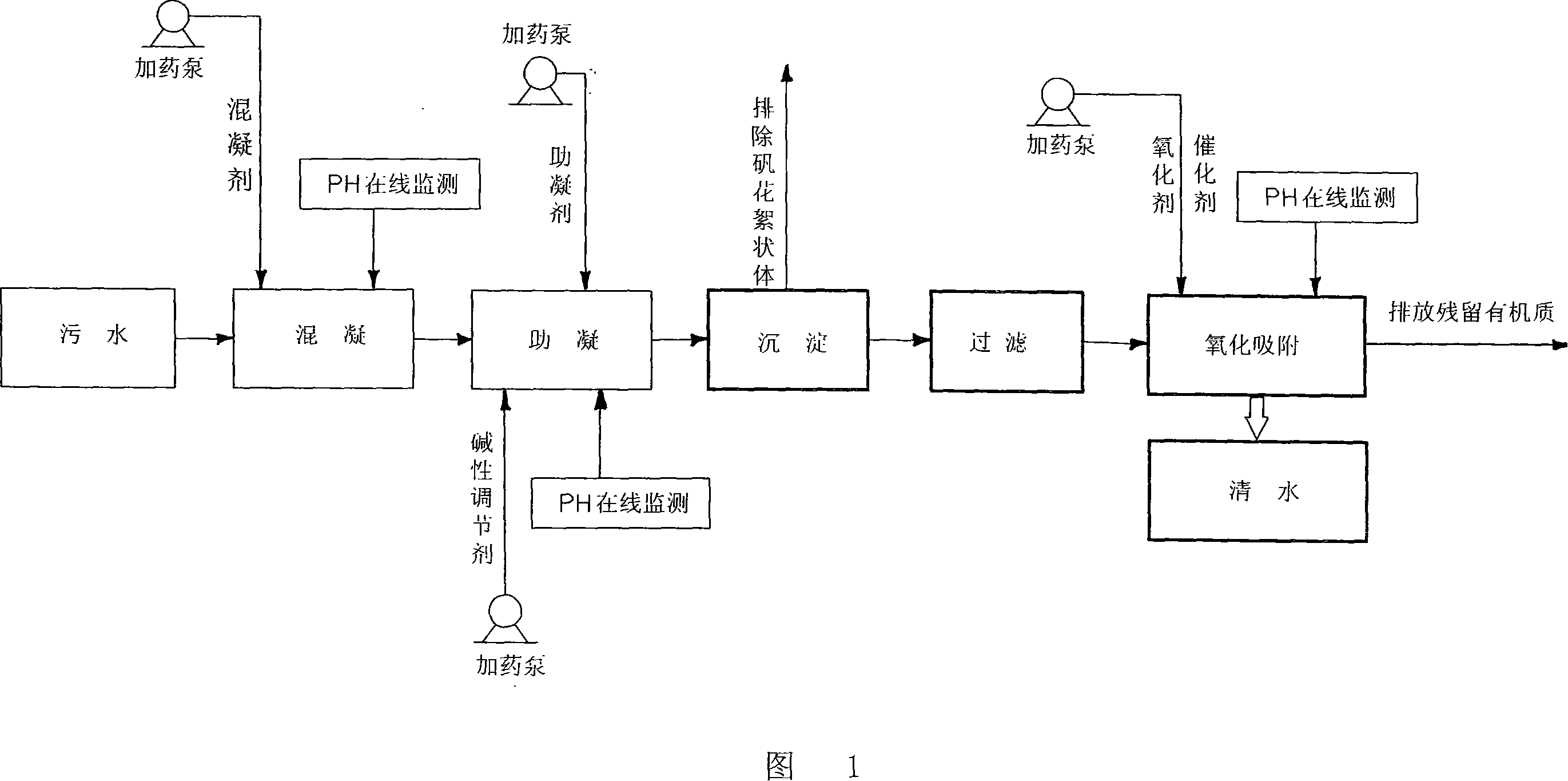

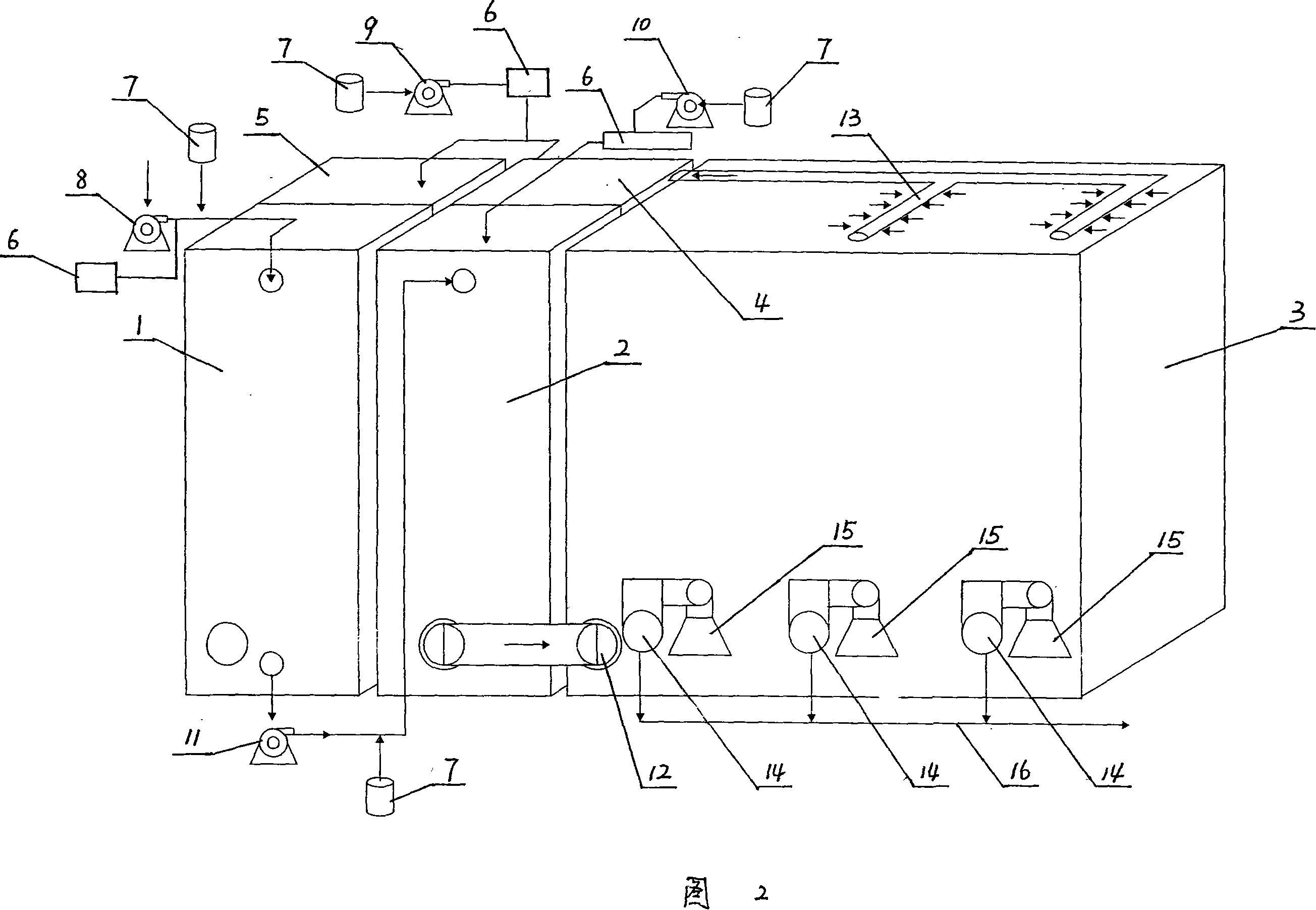

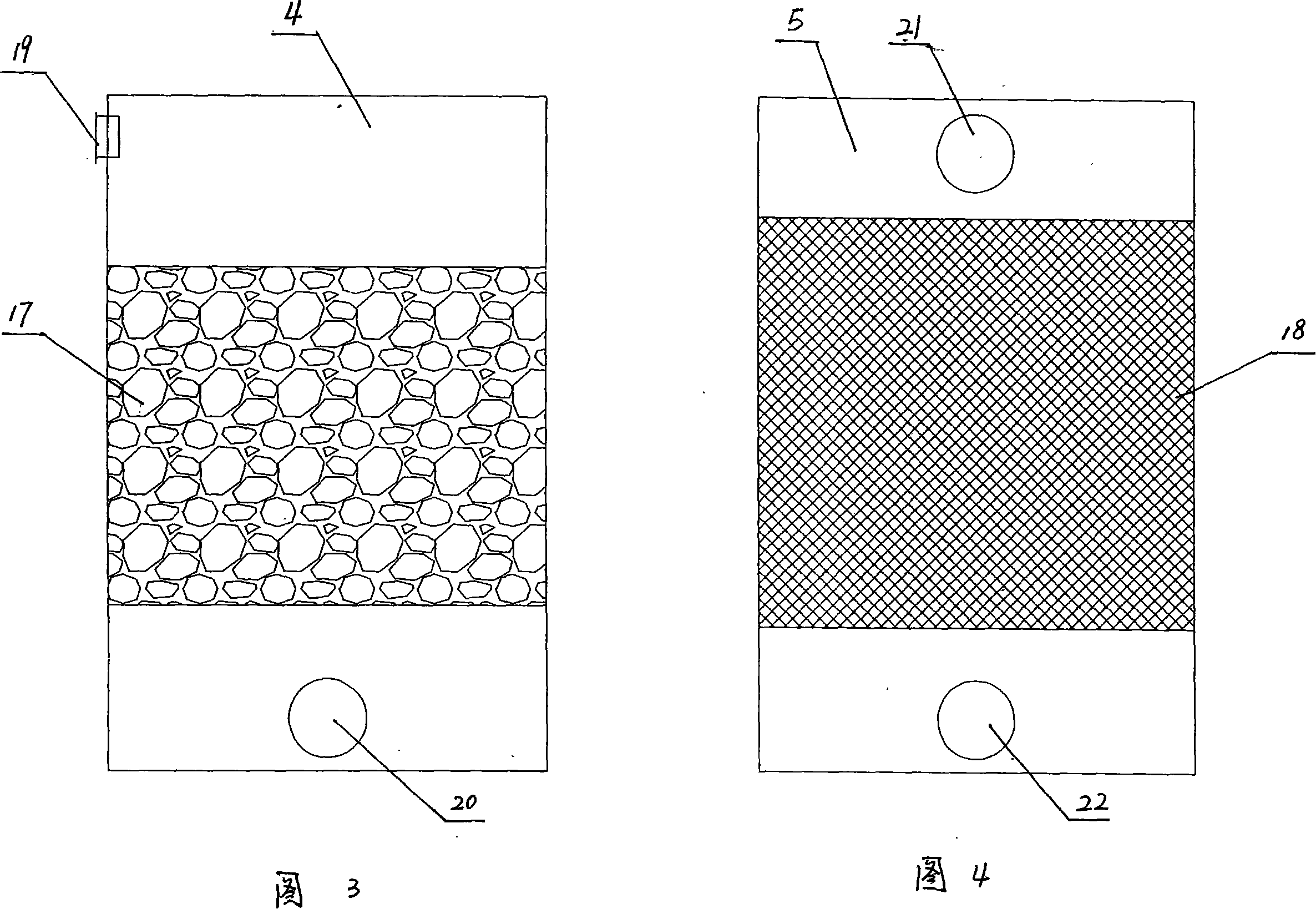

[0037] The continuous treatment process of petroleum drilling sewage includes: coagulation-assisting coagulation-sedimentation-filtration-oxidation adsorption-standard discharge steps, and the specific steps are:

[0038]a. Coagulation: add a coagulant to the sewage in the coagulation tank 1, and monitor the pH value of the drilling sewage on-line to guide the amount of the coagulant added. body, speed up the settling speed of suspended solids in water, remove most of the suspended solids, and remove part of the chromaticity and chemical oxygen demand at the same time, to meet the requirements of the next process;

[0039] b. Coagulation aid: After the uniformly mixed sewage obtained in step a is poured into the coagulation aid tank 2 from the outlet pipe at the lower part of the coagulation tank 1, the alkaline agent is added to mix and adjust, so that the pH value reaches neutral, that is, 6- Within the range of 8, add the coagulation aid; the coagulation aid is added from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com