Electron beam-oxygen synergistic desulfurization and denitrification system and method

A desulfurization and denitration, electron beam technology, applied in the field of flue gas treatment, can solve the problems of limited effect of electron beam irradiation, limited mixing range of ammonia gas and flue gas, and difficulty in achieving the mixing effect of flue gas and ammonia gas. Adverse effects, effects of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

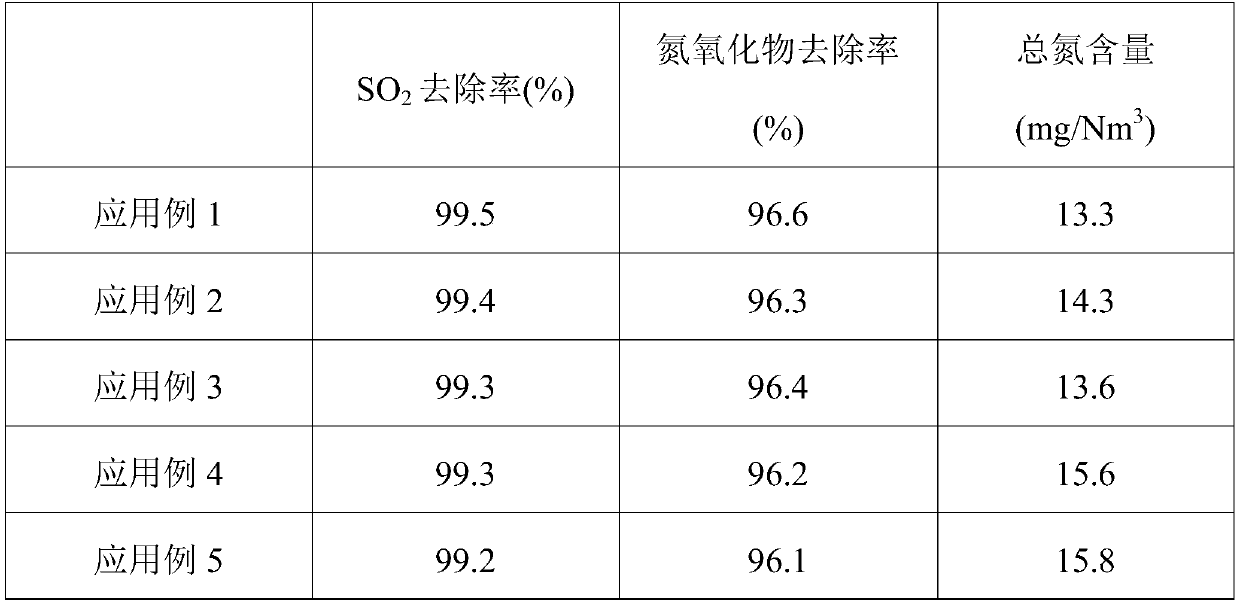

Examples

Embodiment 1

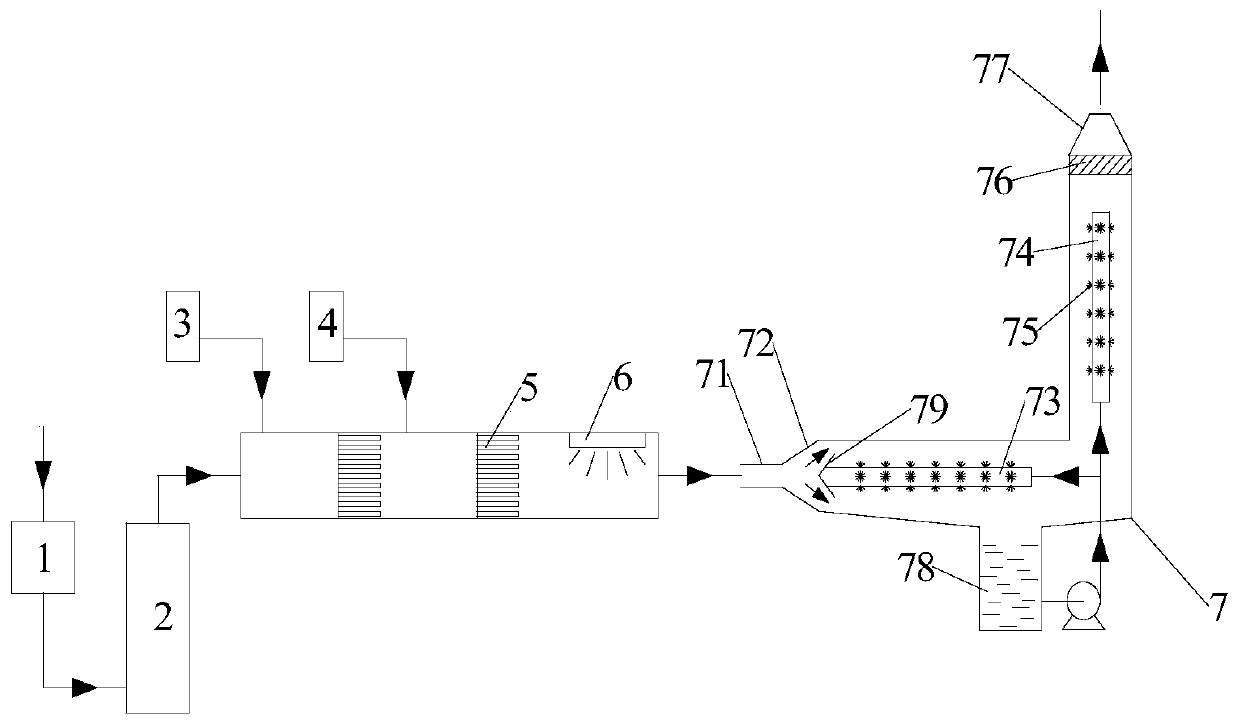

[0072] This embodiment provides an electron beam and oxygen synergistic desulfurization and denitrification system. The electron beam and oxygen synergistic desulfurization and denitrification system includes a dust removal device 1, a spray device 2, a mixing reaction device, an absorption device 7, an oxygen supply device 4, and ammonia Air supply device 3.

[0073] The dust removal device 1 is a cyclone separator, and the spray device 2 is a spray tower.

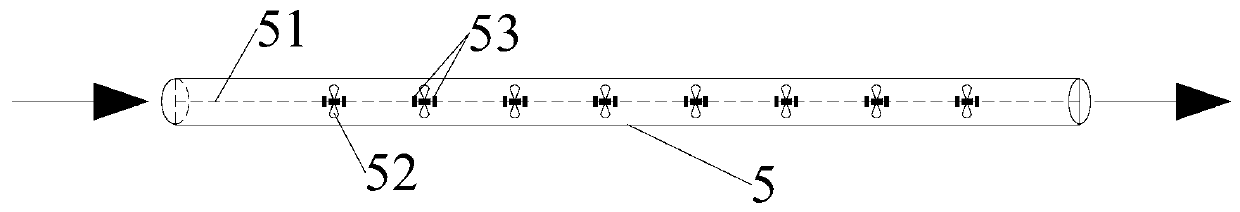

[0074] The mixing reaction device includes three gas distribution tube plates 5 sequentially arranged inside the casing along the flue gas flow direction and an electron beam generating device 6 after the last gas distribution tube plate 5 .

[0075] The flue gas flows through the dedusting device 1, the spraying device 2, the mixing reaction device and the absorption device 7 in sequence; there is an ammonia gas inlet between the flue gas inlet of the mixing reaction device and the first gas distribution tube plate 5, an...

Embodiment 2

[0081] This embodiment provides an electron beam and oxygen synergistic desulfurization and denitrification system. The electron beam and oxygen synergistic desulfurization and denitrification system includes a dust removal device 1, a spray device 2, a mixing reaction device, an absorption device 7, an oxygen supply device 4, and ammonia Air supply device 3.

[0082] The dust removal device 1 is a cyclone separator, and the spray device 2 is a spray tower.

[0083] The mixing reaction device includes two air distribution tube plates 5 sequentially arranged inside the casing along the flue gas flow direction and an electron beam generating device 6 after the last air distribution tube plate 5 .

[0084] The flue gas flows through the dedusting device 1, the spraying device 2, the mixing reaction device and the absorption device 7 in sequence; there is an ammonia gas inlet between the flue gas inlet of the mixing reaction device and the first gas distribution tube plate 5, and ...

Embodiment 3

[0090] This embodiment provides an electron beam and oxygen synergistic desulfurization and denitrification system. The electron beam and oxygen synergistic desulfurization and denitrification system includes a dust removal device 1, a spray device 2, a mixing reaction device, an absorption device 7, an oxygen supply device 4, and ammonia Air supply device 3.

[0091] The dust removal device 1 is a cyclone separator, and the spray device 2 is a spray tower.

[0092] The mixing reaction device includes six air distribution tube plates 5 sequentially arranged inside the casing along the flue gas flow direction and an electron beam generating device 6 behind the last air distribution tube plate 5 .

[0093] The flue gas flows through the dedusting device 1, the spraying device 2, the mixing reaction device and the absorption device 7 in sequence; there is an ammonia gas inlet between the flue gas inlet of the mixing reaction device and the first gas distribution tube plate 5, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com