Desulfurization and denitrification active carbon and preparation method and device thereof

A technology for desulfurization and denitrification and preparation equipment, which is applied in the fields of chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., and can solve problems such as few oxygen-containing groups, poor desulfurization and denitrification effects, and small sulfur capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

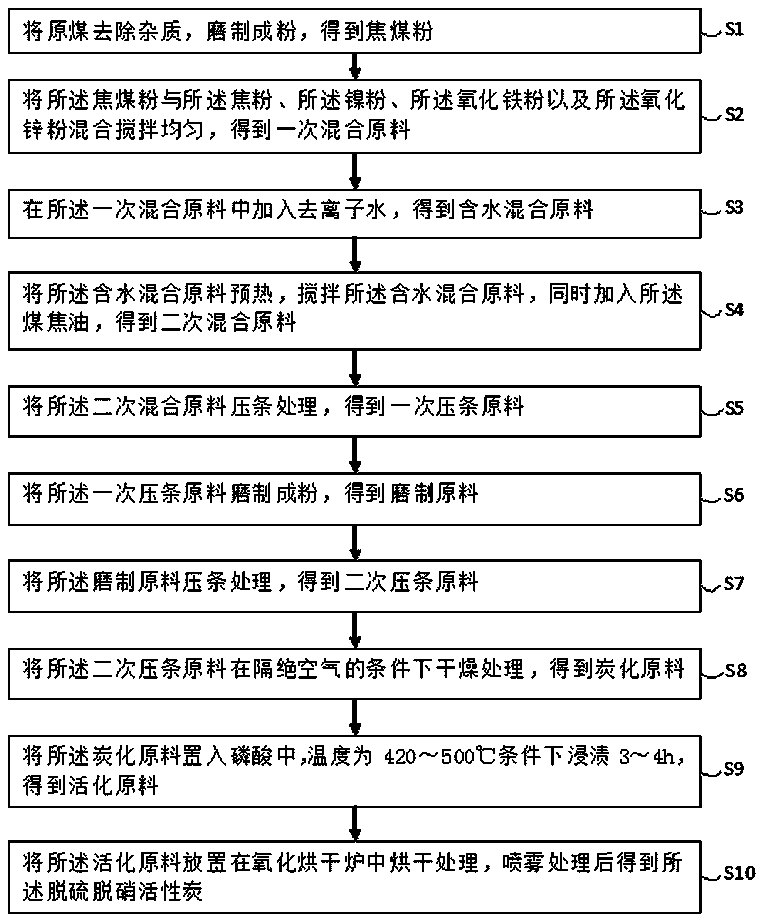

[0039] figure 1 It is a schematic flow diagram of the preparation method of the desulfurization and denitrification activated carbon provided in Example 1, comprising the following steps:

[0040] In step S1, remove impurities from the raw coal, grind it into powder, and obtain coking coal powder.

[0041] In step S2, the coke powder, the coke powder, the nickel powder, the iron oxide powder and the zinc oxide powder are mixed and stirred uniformly to obtain a primary mixed raw material.

[0042] In step S3, deionized water is added to the primary mixed raw material to obtain a water-containing mixed raw material.

[0043] In step S4, the water-containing mixed raw material is preheated, the water-containing mixed raw material is stirred, and the coal tar is added at the same time to obtain a secondary mixed raw material.

[0044] In step S5, the secondary mixed raw material is layered to obtain the primary layered raw material.

[0045] In step S6, the primary layered raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com