A low-temperature desulfurization and denitrification catalyst and flue gas low-temperature integrated desulfurization and denitrification method

A desulfurization, denitrification and catalyst technology, which is applied in the field of low temperature desulfurization and denitrification catalyst and low temperature integrated desulfurization and denitrification of flue gas, can solve the problems of small sulfur capacity of catalyst, high price of activated carbon, oxidation, etc. point, the effect of high desulfurization and denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

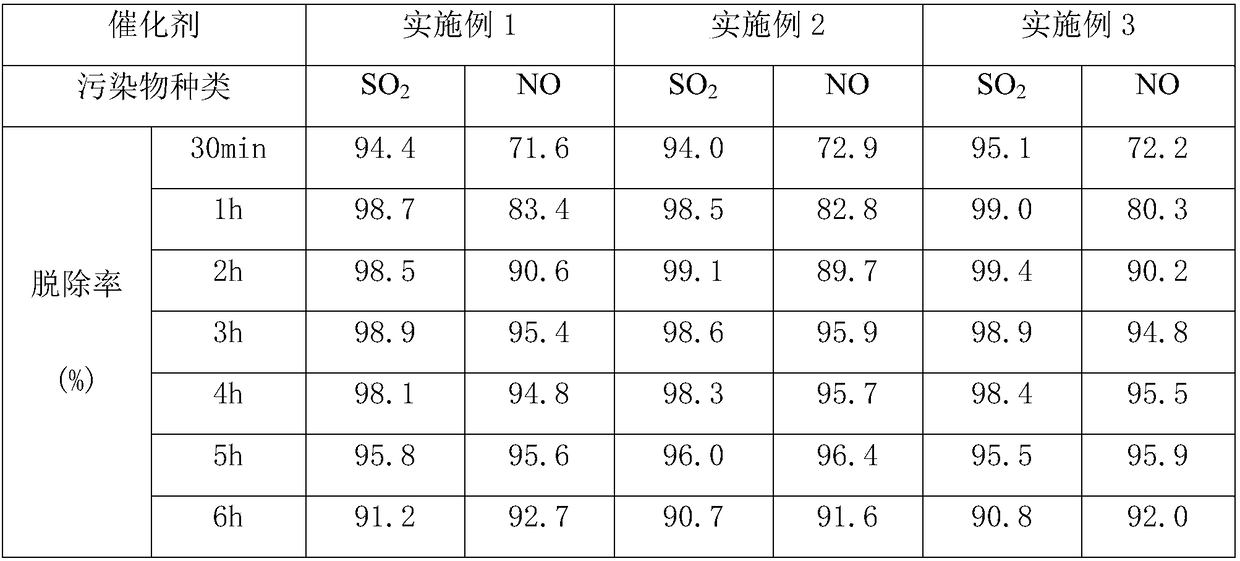

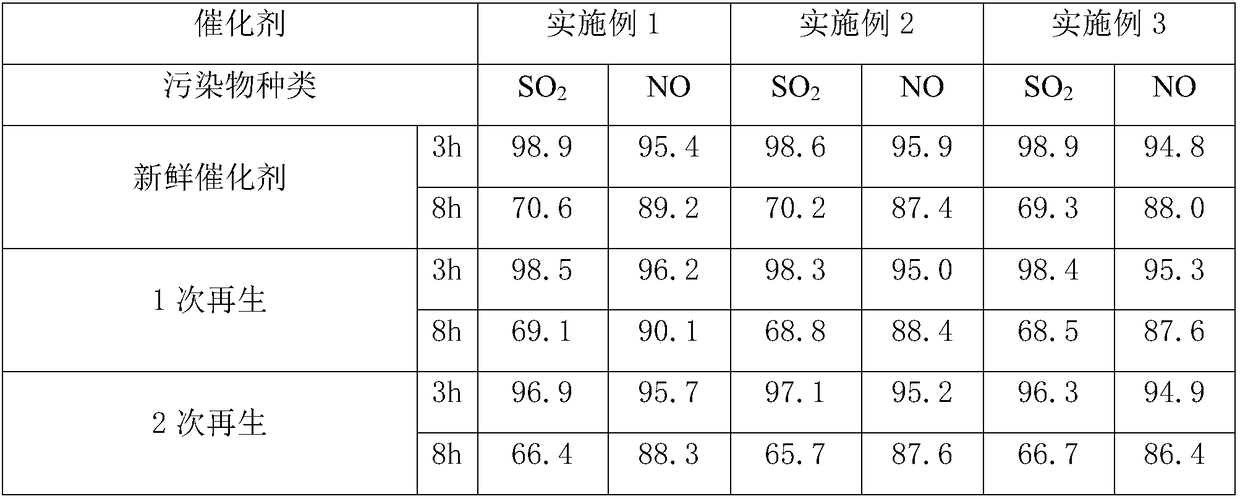

Examples

Embodiment 1

[0032] The low-temperature desulfurization and denitrification catalyst of this embodiment is prepared by the following steps:

[0033] 1) According to the mass ratio of semi-coke and calcium oxide of 8:1, uniformly mix semi-coke particles with a particle size of 8-16 mesh and calcium oxide micropowder with a particle size of 200-300 mesh to obtain a mixture;

[0034] 2) Place the mixture obtained in step 1) in an airtight container, and under the protection of argon, heat up to 420°C at a rate of 8°C / min, and cut off the protective atmosphere; 2 Under the condition of the mixed gas with a volume ratio of 3:7 (the flow rate of the mixed gas per 1g of the mixture is 40ml / min), keep it at 420°C for 40min, then raise the temperature to 800°C at a rate of 15°C / min and keep it for 3h, then cut off Mixed gas, cooled to room temperature under the protection of argon; the product was repeatedly washed with deionized water, and then dried at 110°C for 4 hours to obtain an activated car...

Embodiment 2

[0043] The low-temperature desulfurization and denitrification catalyst of this embodiment is prepared by the following steps:

[0044] 1) According to the mass ratio of semi-coke and calcium oxide of 9:1, uniformly mix semi-coke particles with a particle size of 8-16 mesh and calcium oxide micropowder with a particle size of 200-300 mesh to obtain a mixture;

[0045] 2) Place the mixture obtained in step 1) in an airtight container, and under the protection of argon, raise the temperature to 450°C at a rate of 8°C / min, and cut off the protective atmosphere; 2 Under the condition of the mixed gas with a volume ratio of 4:6 (the flow rate of the mixed gas per 1g of the mixture is 50ml / min), keep it at 450°C for 30min, then raise the temperature to 850°C at a rate of 13°C / min and keep it for 2h, then cut off the mixing gas, and then cooled to room temperature under the protection of argon; the product was repeatedly washed with deionized water, and then dried at 105°C to obtain ...

Embodiment 3

[0054] The low-temperature desulfurization and denitrification catalyst of this embodiment is prepared by the following steps:

[0055] 1) According to the mass ratio of semi-coke and calcium oxide of 10:1, uniformly mix semi-coke particles with a particle size of 8-16 mesh and calcium oxide micropowder with a particle size of 200-300 mesh to obtain a mixture;

[0056] 2) Place the mixture obtained in step 1) in an airtight container, and under the protection of argon, raise the temperature to 435°C at a rate of 6°C / min, and cut off the protective atmosphere; 2 Under the condition of the mixed gas with a volume ratio of 3.5:6.5 (the flow rate of the mixed gas per 1g of the mixture is 60ml / min), keep it at 435°C for 35min, then raise the temperature to 830°C at a rate of 12°C / min and keep it for 2.5h, then Cut off the mixed gas and cool to room temperature under the protection of argon; the product was repeatedly washed with deionized water, and then dried at 115°C to obtain an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com