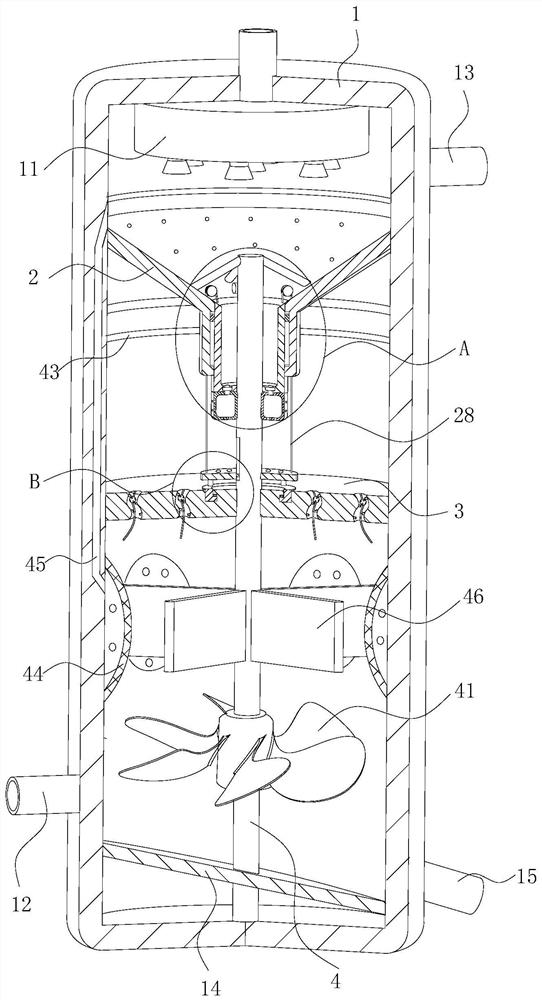

Biomass fuel desulfurization and denitrification system

A biomass fuel, desulfurization and denitrification technology, applied in the field of biomass fuel desulfurization and denitrification system, can solve the problems of dry wall, affecting the effect of flue gas desulfurization and denitrification, uneven liquid distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

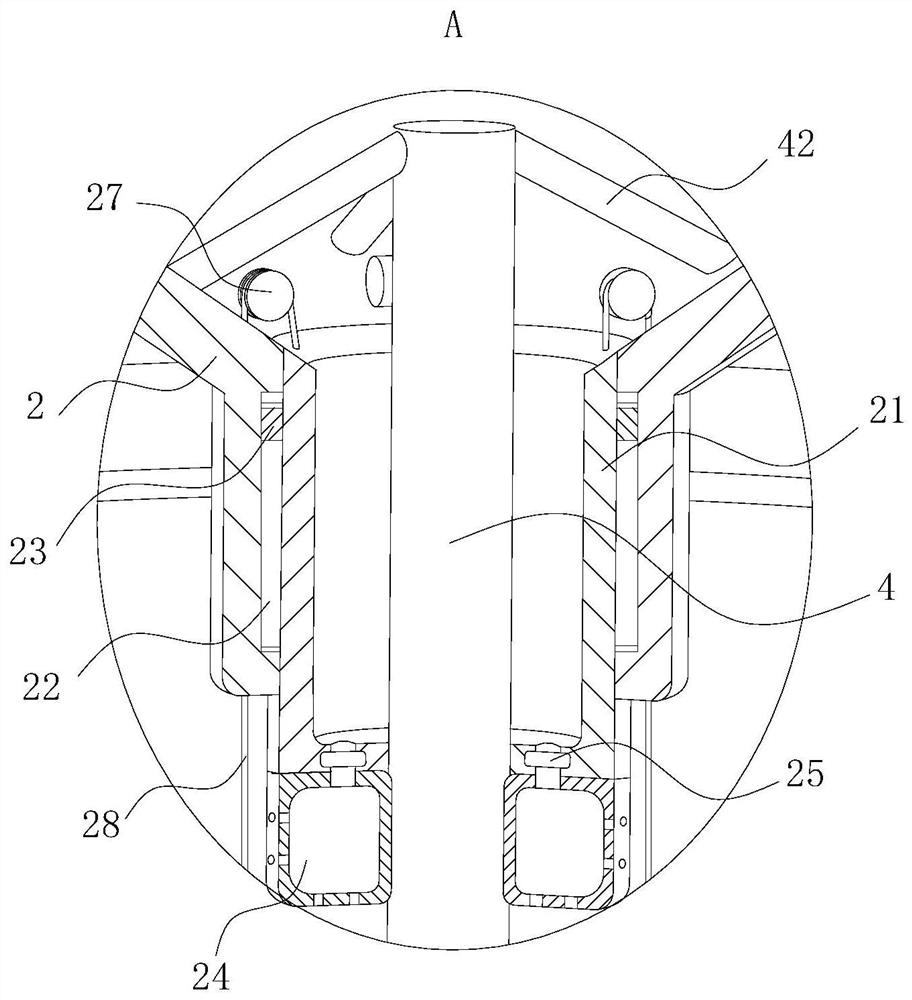

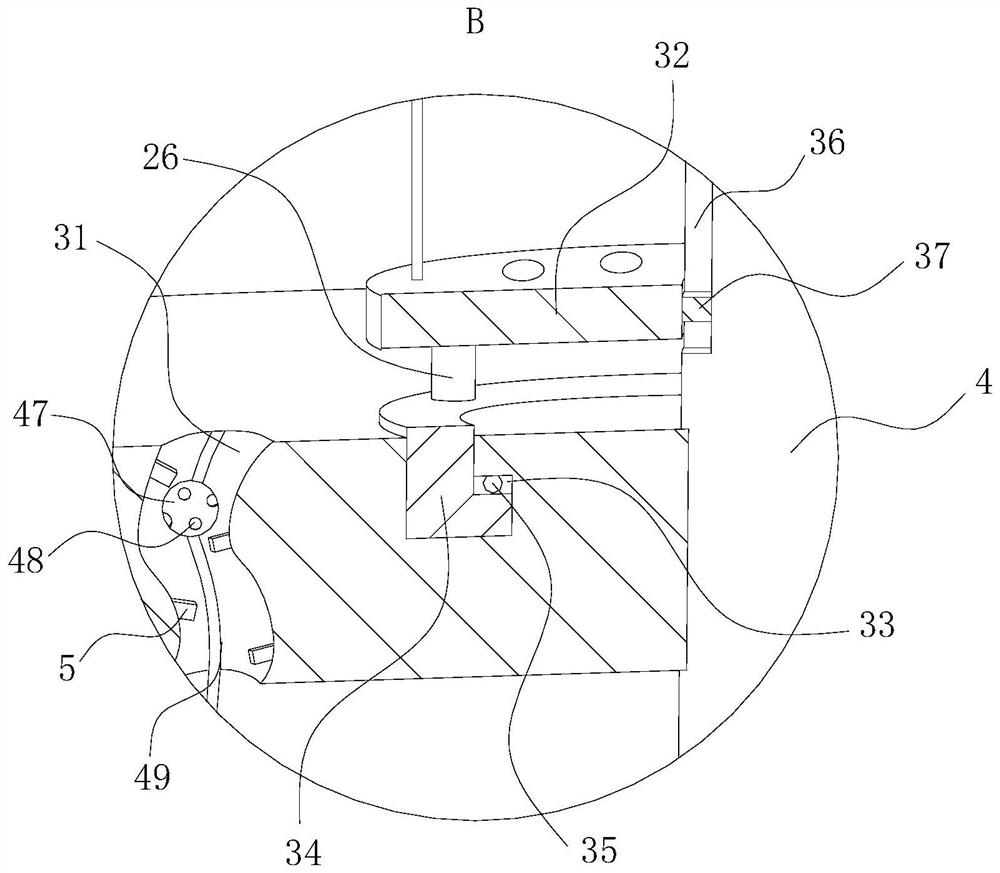

[0027] As an embodiment of the present invention, the middle part of the tower body 1 is rotatably connected with a rotating shaft 4, and the lower end of the rotating shaft 4 is provided with an impeller 41. The impeller 41 rotates; the second connecting rod 42 evenly distributed is fixedly connected between the upper end of the rotating shaft 4 and the inner wall of the guide cylinder 2, and the sliding cylinder 21 and the packing plate 3 are all connected to the rotating shaft 4 in rotation; the packing plate 3 The middle part of the upper surface is provided with an annular groove 33 with an "L"-shaped design in section, and a swivel 34 with an "L"-shaped design in the annular groove 33 is rotatably connected therein. Evenly arranged balls 35 are arranged between them, and the upper surface of the swivel 34 is fixedly connected with the extruding plate 32 through the evenly arranged first connecting rod 26; A second clamping block 37 is fixedly connected to the pressing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com