Desulfurization denitrification agent for flue gas, production method and application thereof

A technology for desulfurization and denitrification and flue gas, which is applied in the field of dry denitrification of flue gas and dry desulfurization and denitrification agent, which can solve the problems of low operating and processing costs, high system investment costs, high operating and processing costs, and complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] According to the formula in Table 1, all the components were mixed evenly to obtain the desulfurization and denitrification agent F1. The desulfurization and denitrification agent is used for dry desulfurization and denitrification, and the flow velocity of the flue gas is 2.5m / s; other parameters of the flue gas inlet and flue gas outlet are shown in Tables 2 and 3. Using this desulfurization and denitrification agent for dry desulfurization and denitrification, the concentration of sulfur dioxide in the purified flue gas is 47mg / Nm 3 , the concentration of nitrogen oxides is 99mg / Nm 3 . The desulfurization efficiency reaches 97.94%, and the denitrification efficiency is 84.59%.

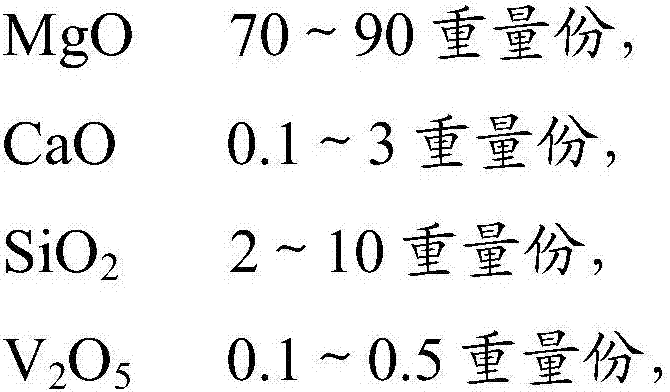

[0054] Table 1. Formula of desulfurization and denitrification agent F1

[0055]

[0056]

[0057] Table 2. Flue gas inlet parameters

[0058] serial number

parameter

unit

value

1

Inlet flue gas volume (working condition)

m 3 / h

780000

...

Embodiment 2

[0062] According to the formula in Table 4, all components were mixed evenly to obtain desulfurization and denitrification agent F2. Using this desulfurization and denitrification agent for dry desulfurization and denitrification, the concentration of sulfur dioxide in the purified flue gas is 34mg / Nm 3 , the concentration of nitrogen oxides is 78mg / Nm 3 . The desulfurization efficiency reaches 98.58%, and the denitrification efficiency is 88.49%. The parameters of the flue gas inlet are the same as in Example 1, and the parameters of the flue gas outlet are shown in Table 5.

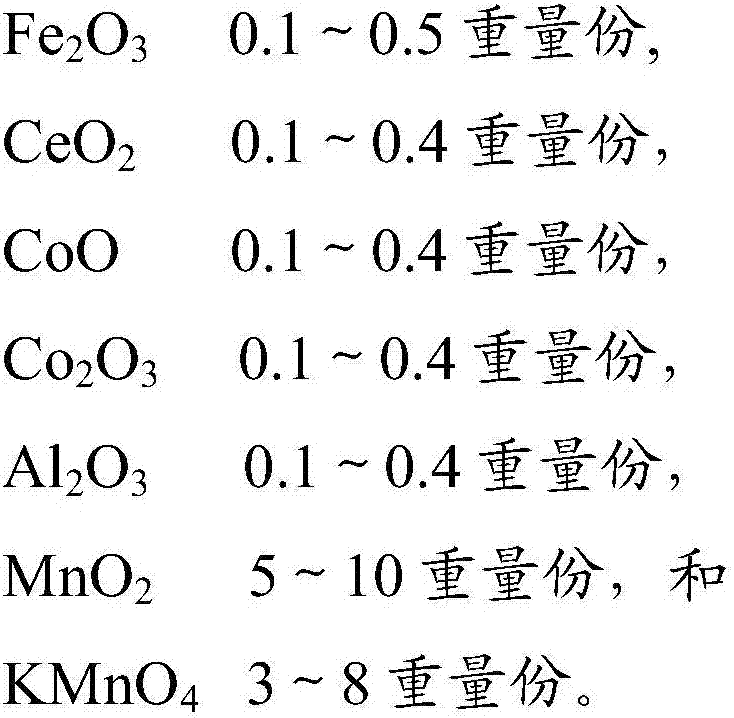

[0063] Table 4. Formula of desulfurization and denitrification agent F2

[0064]

[0065] Table 5. Flue gas outlet parameters

[0066] serial number

Embodiment 3

[0068] According to the formula in Table 6, the components were mixed evenly to obtain the desulfurization and denitrification agent F3. Using this desulfurization and denitrification agent for dry desulfurization and denitrification, the concentration of sulfur dioxide in the purified flue gas is 26mg / Nm 3 , the concentration of nitrogen oxides is 66mg / Nm 3 . The desulfurization efficiency reaches 98.92%, and the denitrification efficiency is 90.23%. The parameters of the flue gas inlet are the same as in Example 1, and the parameters of the flue gas outlet are shown in Table 7.

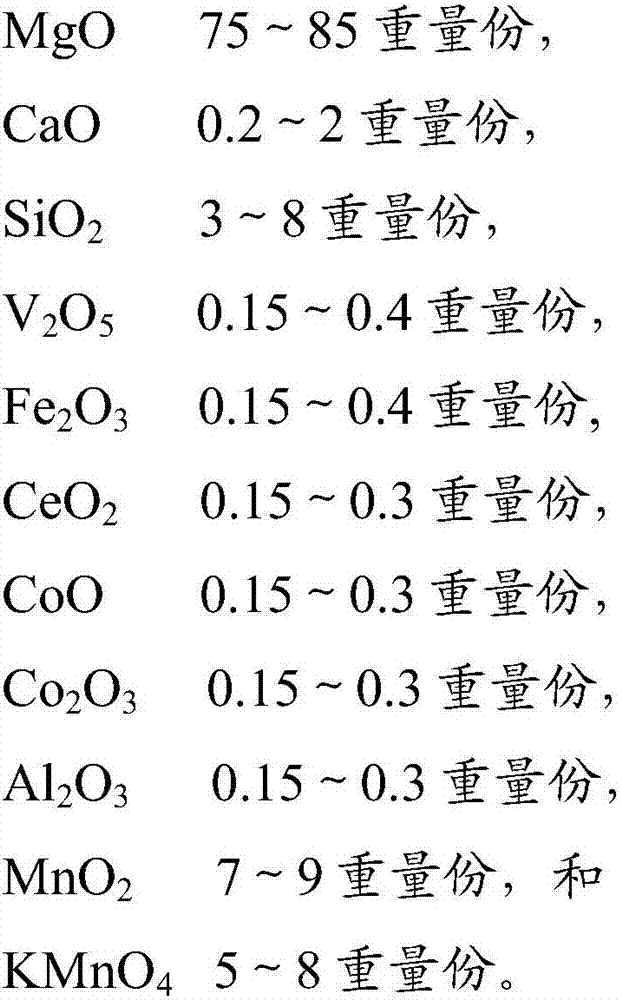

[0069]Table 6. Formula of desulfurization and denitrification agent F3

[0070]

[0071]

[0072] Table 7. Flue gas outlet parameters

[0073] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com