Pulse corona plasma reaction and absorption catalysis desulfurization denitration method and device

A plasma, adsorption and catalysis technology, applied in separation methods, chemical instruments and methods, greenhouse gas capture, etc., can solve the problems of unreachable, troublesome and limited catalyst life maintenance, and achieve enhanced desulfurization and denitrification capacity and good economic utilization. Value, simple effect of device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

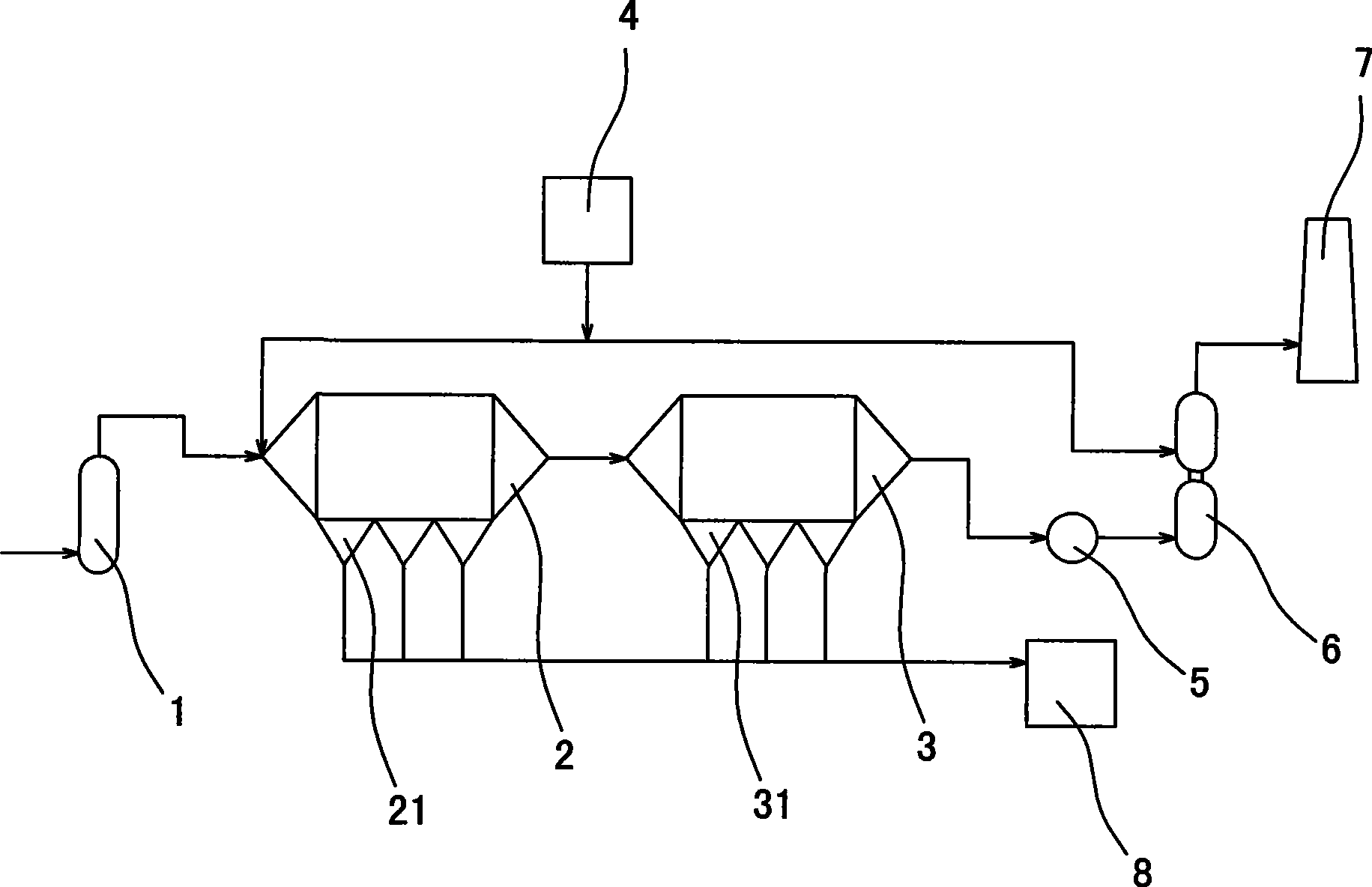

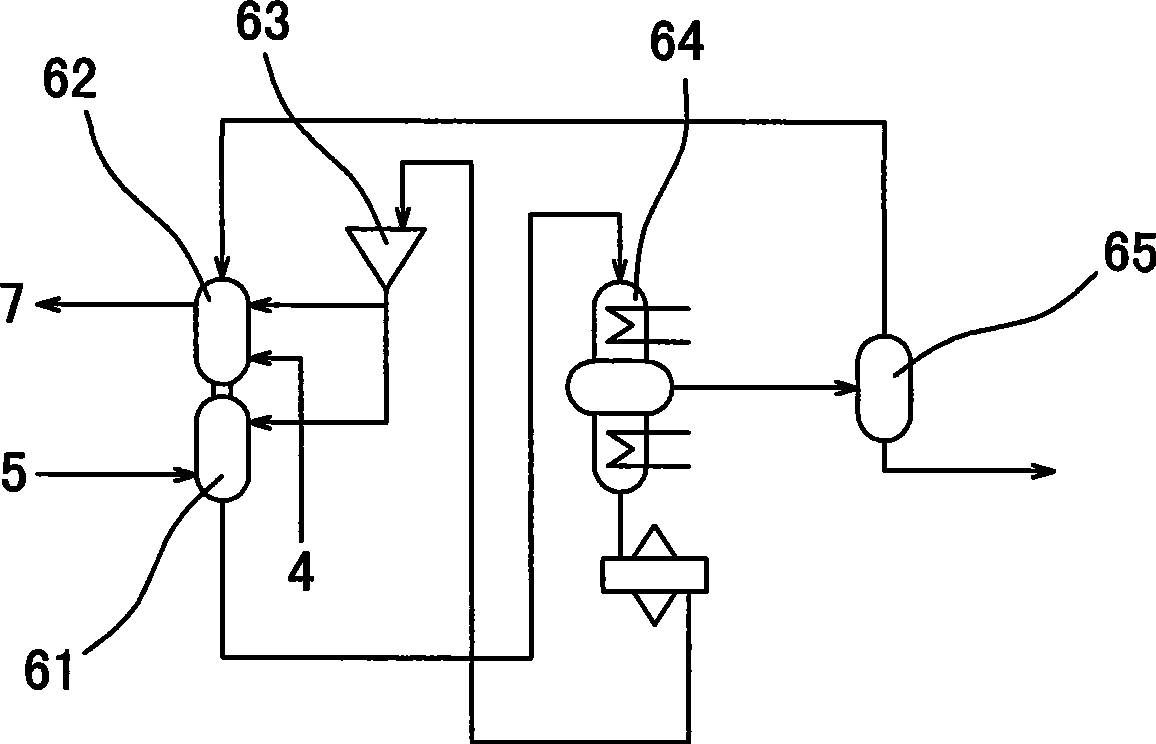

[0014] Such as figure 1 , figure 2 As shown, pulsed corona plasma reaction and adsorption catalytic desulfurization and denitrification methods:

[0015] The flue gas processed by the dust collector enters the conditioning tower 1, and the temperature and humidity of the flue gas are adjusted (the flue gas is adjusted to a temperature of 58-62 °C and a humidity of 10% in the conditioning tower 1), so as to meet The conditions required for the plasma reaction;

[0016] The flue gas regulated by the tempering tower 1 enters the plasma reactor 2, and the flue gas generates a strong plasma corona discharge between the discharge electrode and the ground electrode of the plasma reactor 2, and at the same time flows to the plasma reactor Add additive ammonia in 2 to carry out desulfurization and denitrification, (the additive ammonia added in the plasma reactor 2 and the SO in the flue gas 2 and NO X The equivalence ratio is 1:1), generates the mixed ammonium salt that is made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com