Novel integrated apparatus for conditioning and desulphurizing flue gas by dry method

A desulfurization device, flue gas technology, applied in the direction of combined devices, gas treatment, separation methods, etc., can solve the problems of insufficient utilization of desulfurization waste residue, unfavorable resource recycling, low concentration of sulfur oxides, etc., to improve the properties of smoke and dust, design Sophisticated, Unique and Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

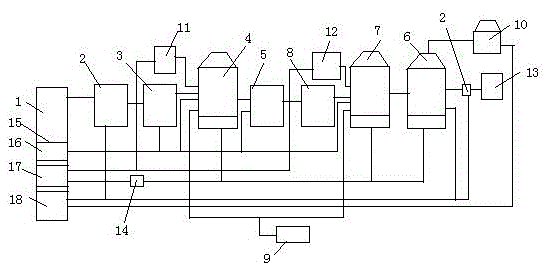

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

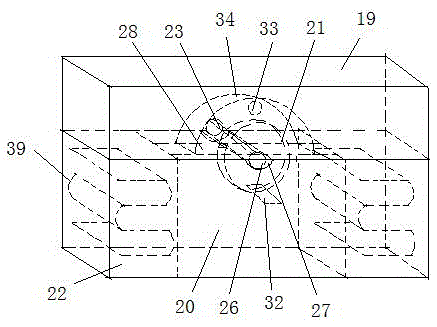

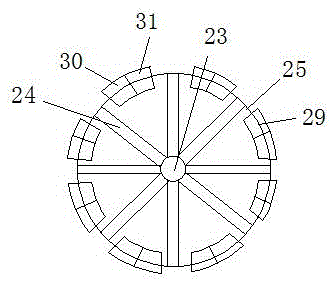

[0023]It can be seen from the accompanying drawings that a new type of dry flue gas conditioning and desulfurization integrated device includes a glass melting cellar 1, a first cooling device 2, an adsorption dust removal device 3, a first desulfurization device 4, a centrifugal dust removal device 5, and a denitrification device 6 , the second desulfurization device 7, the atomizer 8, the waste slag treatment device 9, the chimney 10, the first liquid storage tank 11, the second liquid storage tank 12, the third liquid storage tank 13 and the air tank 14, the glass melting cellar 1 The bottom end is provided with a waste heat boiler 15, and the waste heat boiler 15 is provided with a heat exchange device, and the heat exchange device is provided with a high temperature heat exchange device 16, a medium temperature heat exchange device 17 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com