Multilevel plasma ultralow intensified smoke emission control system and multilevel plasma ultralow intensified smoke emission control method

An emission control system, plasma technology, applied in separation methods, chemical instruments and methods, electrostatic separation, etc., can solve the problem of neglecting denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

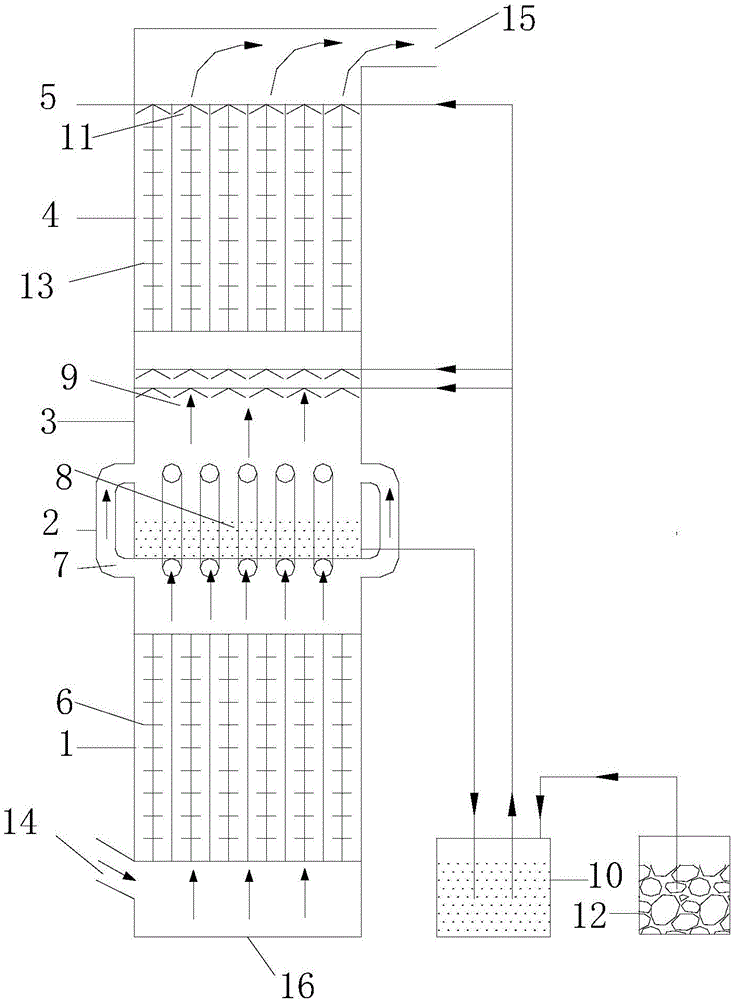

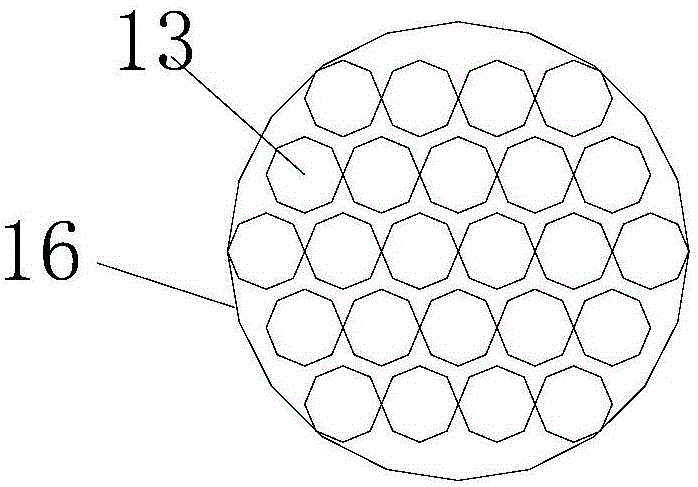

[0081] like figure 1 As shown, a plasma-enhanced multi-stage absorption flue gas ultra-low emission control system, its main structure is a reaction tower 16, and the reaction tower is sequentially set up from bottom to top as a plasma dry oxidation section 1 (for NO oxidation), Gas conversion section 2 (isolated spray absorption section and plasma dry oxidation section), spray absorption section 3 (desulfurization, denitrification and dust removal of flue gas), plasma oxidation absorption section 4 (further desulfurization, denitrification and dust removal of flue gas) and pole Plate shower 5 (spray NaOH).

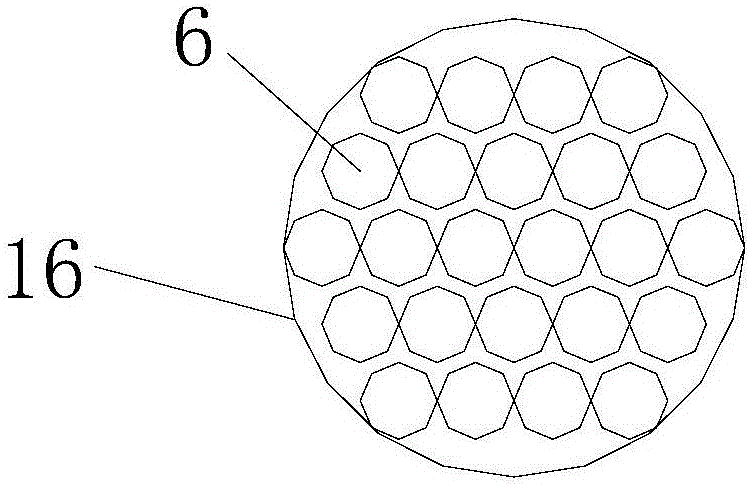

[0082] A number of first corona discharge plasma reactors 6 are arranged in the plasma dry oxidation section 1. In this embodiment, a single corona discharge plasma generator here is a wire-drum structure, and consists of a cylindrical pole plate and the circular polar line located in the center of the cylindrical plate, all the first corona discharge plasma reactors are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com