Desulphurization and denitration device and method

A technology of desulfurization and denitrification and layer arrangement, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of high investment and operation costs and low oxidation efficiency, reduce investment land occupation and operation costs, and improve detoxification. The effect of removing rate and reducing injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

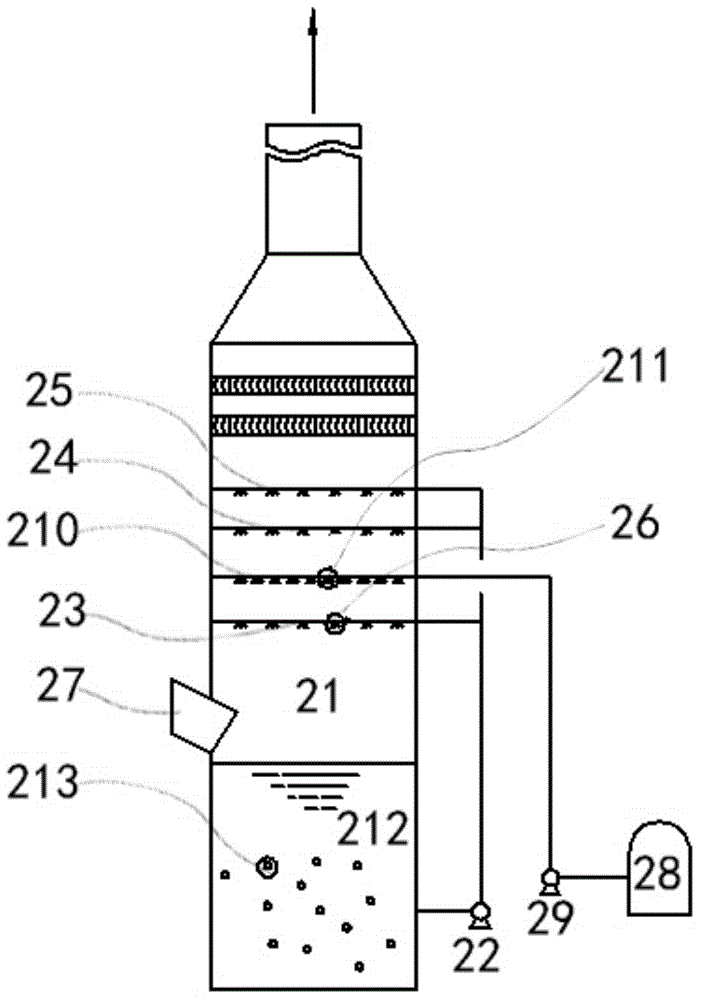

[0125] This embodiment relates to a desulfurization and denitrification device and method of the present invention. Such as image 3 As shown, the desulfurization and denitrification device includes desulfurization and denitrification equipment 21 and hydrogen peroxide supply equipment (including H 2 o 2 storage tank 28 and injection pump 29) and the circulating pump 22 as the slurry circulation conveying equipment, the inside of the desulfurization and denitrification equipment 21 is provided with a spray absorbing area (comprising the first layer of spray absorbing layer 23, the second layer of spray absorbing layer 24 and The third layer spray absorbing layer 25), H 2 o 2 The oxidation reaction layer 210 and the slurry storage area 212 are sprayed. Among them, H 2 o 2 The spray oxidation reaction layer 210 is arranged between the first spray absorption layer 23 and the second spray absorption layer 24 . The slurry storage area 212 is provided with a hydrogen peroxide...

Embodiment 2

[0130] This embodiment relates to another desulfurization and denitrification device and method of the present invention. The difference between this desulfurization and denitrification device and the desulfurization and denitrification device in Example 1 is that H 2 o 2 The spray oxidation reaction layer is arranged between the second spray absorption layer and the third spray absorption layer. The distance between the first spray absorbing layer and the second spray absorbing layer is 2.0 meters. The distance between the second spray absorbing layer and the third spray absorbing layer is 3.0 meters. The hydrogen peroxide spray oxidation reaction layer is 1.6 meters away from the second spray absorption layer. other settings and figure 1 The device shown in Example 1 is the same.

[0131] The desulfurization and denitrification method using this desulfurization and denitrification device is the same as the desulfurization and denitrification method in Example 1. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com