Metallurgical solid waste based pressed active carbon for desulfurization and denitrification of flue gas and preparation method of pressed active carbon

A technology for forming activated carbon, desulfurization and denitrification, applied in separation methods, climate sustainability, chemical instruments and methods, etc., can solve the problems of low specific surface area of activated carbon, low desulfurization and denitrification efficiency, low added value of activated carbon, etc., to achieve the preparation method Simple and easy to implement, realize high-value utilization, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

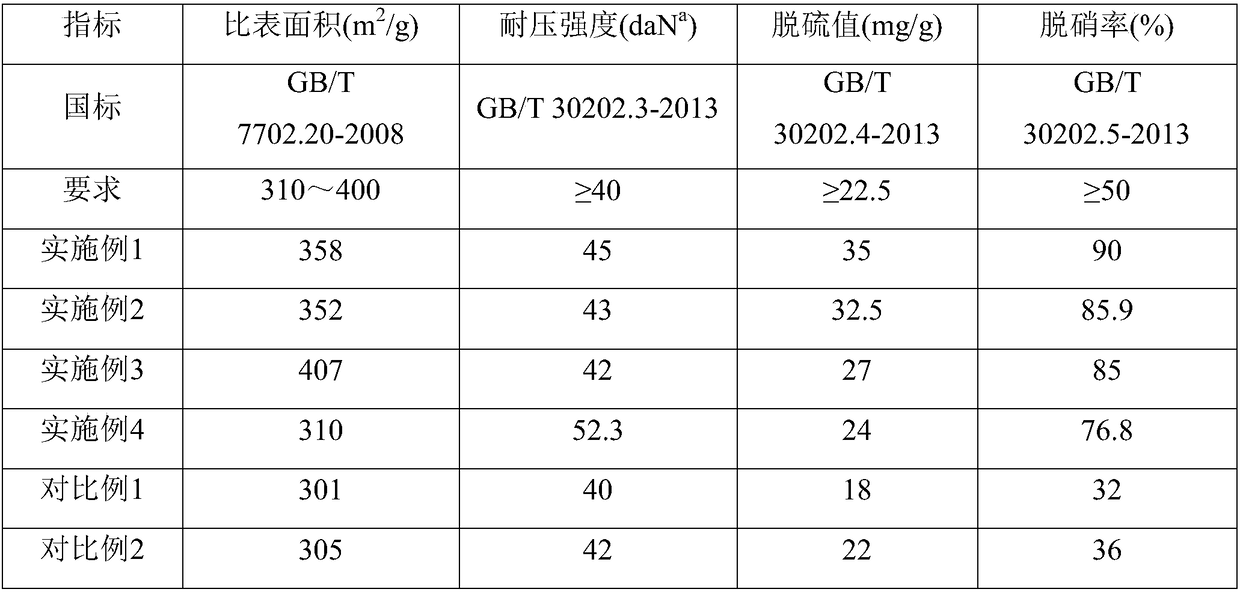

Examples

Embodiment 1

[0037] A shaped activated carbon for flue gas desulfurization and denitrification based on metallurgical solid waste, the preparation method of which comprises the following steps:

[0038] 1) The raw materials are weighed, each raw material and its mass percentage include: powdered activated carbon 70%, forming agent 30%, wherein each component in the forming agent and its mass percentage include: steel slag powder 25%, slag powder 70% , desulfurization ash 5%;

[0039]2) The weighed steel slag, slag and desulfurization ash were placed in an oven at 105°C for drying, and then ground separately to control the specific surface area to 450m 2 / kg (and the particle size is less than 1mm and the content is greater than 90%); the steel slag after grinding, slag and desulfurization ash are evenly mixed to obtain a molding agent for subsequent use;

[0040] 3) Take powdered activated carbon in proportion (specific surface area 400m 2 / g particle size 1mm or less content greater tha...

Embodiment 2

[0042] A shaped activated carbon for flue gas desulfurization and denitrification based on metallurgical solid waste, the preparation method of which comprises the following steps:

[0043] 1) The raw materials are weighed, each raw material and its mass percentage include: powdered activated carbon 75%, forming agent 25%, wherein each component in the forming agent and its mass percentage include: steel slag powder 28%, slag powder 65% , desulfurization ash 7%;

[0044] 2) The weighed steel slag, slag and desulfurization ash were placed in an oven at 105°C for drying, and then ground separately to control the specific surface area to 480m 2 / kg; Mix the ground steel slag, slag and desulfurization ash evenly to obtain a forming agent for subsequent use;

[0045] 3) Take powdered activated carbon in proportion (specific surface area is 380m 2 / g, the particle size is less than 1mm and the content is greater than 90%) and molding agent, pour in the mixer, pour into the water t...

Embodiment 3

[0047] A shaped activated carbon for flue gas desulfurization and denitrification based on metallurgical solid waste, the preparation method of which comprises the following steps:

[0048] 1) The raw materials are weighed, each raw material and its mass percentage include: powdered activated carbon 80%, forming agent 20%, wherein each component in the forming agent and its mass percentage include: steel slag powder 30%, slag powder 62% , desulfurization ash 8%;

[0049] 2) The weighed steel slag, slag and desulfurization ash were placed in an oven at 105°C for drying, and then ground separately to control the specific surface area to 500m 2 / kg (and the particle size is less than 1mm and the content is greater than 90%); the steel slag after grinding, slag and desulfurization ash are evenly mixed to obtain a molding agent for subsequent use;

[0050] 3) Take powdered activated carbon (the specific surface area is 420, and the content is greater than 90% below particle diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com