Desulphurization-denitration integrated method and apparatus for low temperature flue gas

A technology for desulfurization, denitrification, and low-temperature flue gas, which is applied to chemical instruments and methods, gas treatment, and separation methods. The effect of desulfurization and denitrification ability, improvement of removal efficiency and reduction of operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

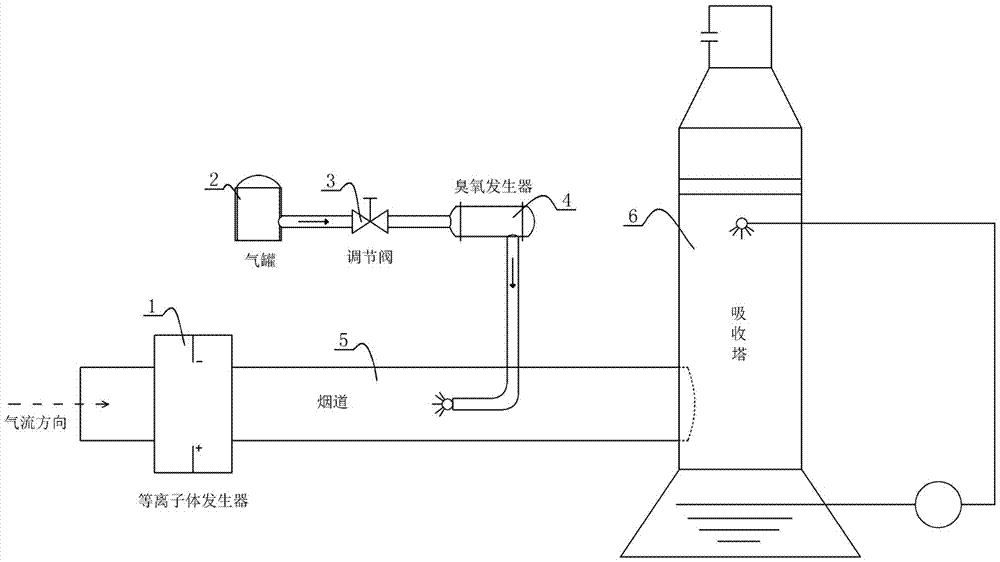

Embodiment 1

[0031] Such as figure 1 As shown, the structural schematic diagram of the first embodiment of the present invention is given. The method for the integration of low-temperature flue gas desulfurization and denitrification shown is composed of a plasma desulfurization and denitrification device and an ozone oxidation desulfurization and denitrification device. The plasma desulfurization and denitrification device consists of The plasma generator 1 is configured, and the plasma generator 1 is installed at the front end of the flue 5 . The ozone oxidation desulfurization and denitrification device is composed of a gas tank 2, a regulating valve 3, and an ozone generator 4. A cavity or oxygen is stored in the gas tank 2 as a gas source for preparing ozone. The regulating valve 3 is arranged on the gas tank 2 and the ozone generator On the pipeline between the devices 4, in order to realize the adjustment of the gas flow. The ozone generated by the ozone generator 4 is passed into ...

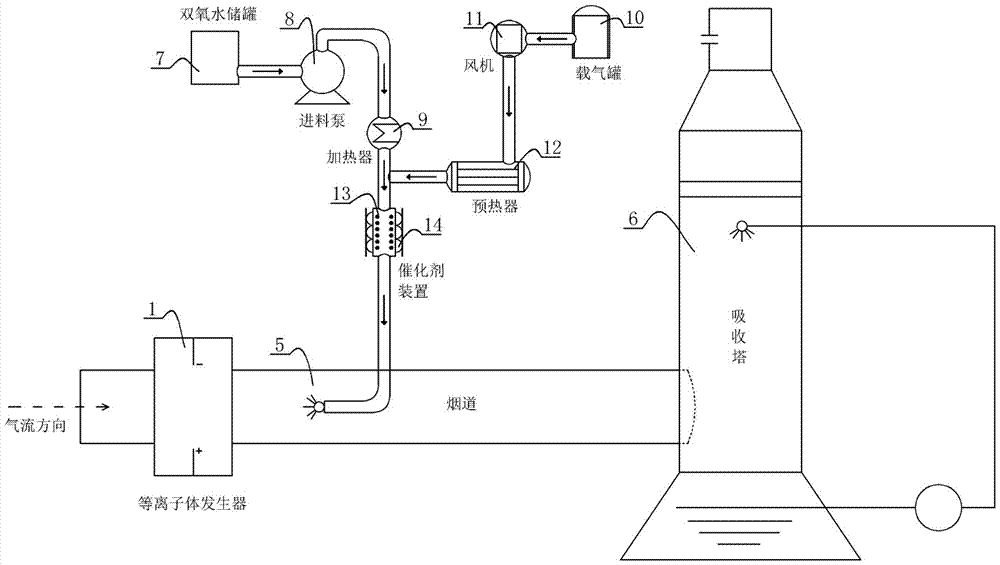

Embodiment 2

[0034] Such as figure 2 As shown, the structural schematic diagram of the second embodiment of the present invention is given. The integrated method of low-temperature flue gas desulfurization and denitrification shown is composed of a plasma desulfurization and denitrification device, a hydrogen peroxide catalytic activation desulfurization and denitrification device, and a plasma desulfurization and denitrification device. It consists of a plasma generator 1 and is installed at the front end of the flue. The hydrogen peroxide catalytically activated desulfurization and denitrification device is composed of a hydrogen peroxide storage tank 7, a feed pump 8, a heater 9, a carrier gas tank 10, a fan 11, a preheater 12, and a catalyst device 13. Liquid hydrogen peroxide is stored in the hydrogen peroxide storage tank 7. The feed pump 8 is used to pump the liquid hydrogen peroxide in the hydrogen peroxide storage tank 7 into the heater 9, and the heater 9 is used to heat the hyd...

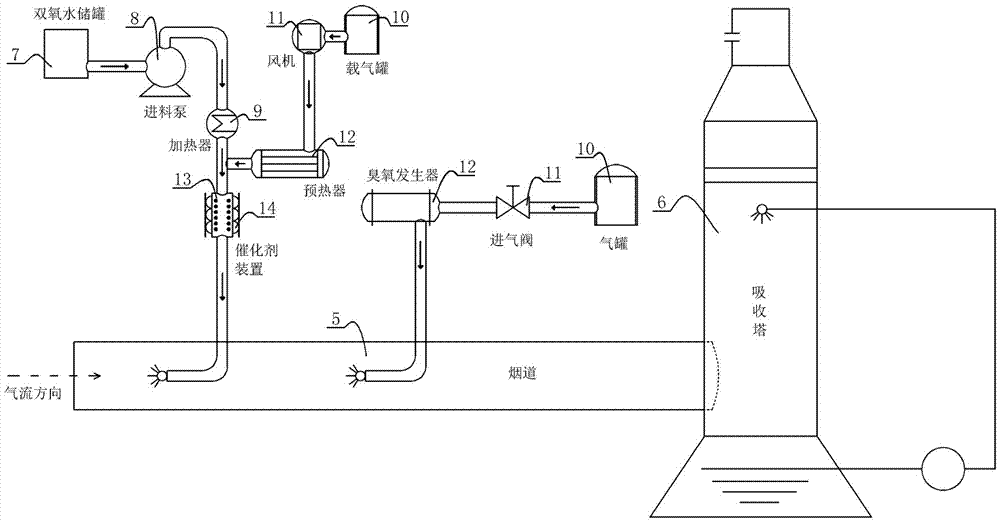

Embodiment 3

[0038] Such as image 3 As shown, the structural schematic diagram of the third embodiment of the present invention is given. The integrated method of low-temperature flue gas desulfurization and denitrification shown is composed of a hydrogen peroxide catalytic activation desulfurization and denitrification device and an ozone oxidation desulfurization and denitrification device. The hydrogen peroxide catalytic activation desulfurization and denitrification device The device is arranged at the front end of the ozone oxidation desulfurization and denitrification device. The ozone oxidation desulfurization and denitrification device is the same as that in Embodiment 1, and the hydrogen peroxide catalytic activation desulfurization and denitrification device is the same as that in Embodiment 2, and will not be repeated here.

[0039] During the working process, the flue gas first removes most of the SO by hydroxyl radicals and hydrogen peroxide 2 and a small amount of NO, this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com