Preparation method of activated coke

A technology of activated coke and coking coal, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as poor desulfurization and denitrification effects, poor adsorption capacity, and low ignition point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

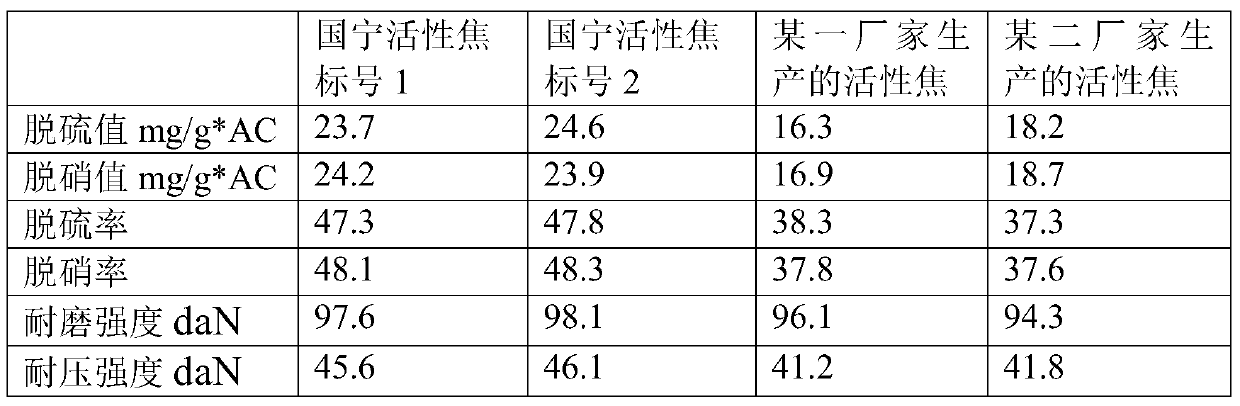

[0015] In order to more clearly illustrate the technical solutions of the embodiments of the present invention, further description will be given below.

[0016] An embodiment of the present invention provides a method for preparing active coke, comprising the following steps:

[0017] Ingredients: Anthracite, coking coal, and special additives are weighed according to the mass ratio of 50-60%: 30-40%: 5-15%, and mixed evenly to form a mixture; preferably, anthracite, coking coal, and special additives are weighed according to the mass ratio 60%: 40%: 5%, or 50%: 30%: 10% of anthracite, coking coal, and special additives according to the mass ratio, or any combination of values falling within the above range.

[0018] Milling: grinding the mixture to form mixed powder;

[0019] Kneading: Add the mixed powder, coal tar, asphalt, and water into the kneading pot according to the mass ratio of 60-80%: 15-25%: 3-6%: 3-8%, and mix to form a wet mixture. The order of adding coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com