Regenerative device and method for desulfurized and denitrified active coke

A regeneration device, nitric acid active coke technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., to achieve high device efficiency, avoid local overheating, and increase heat transfer intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

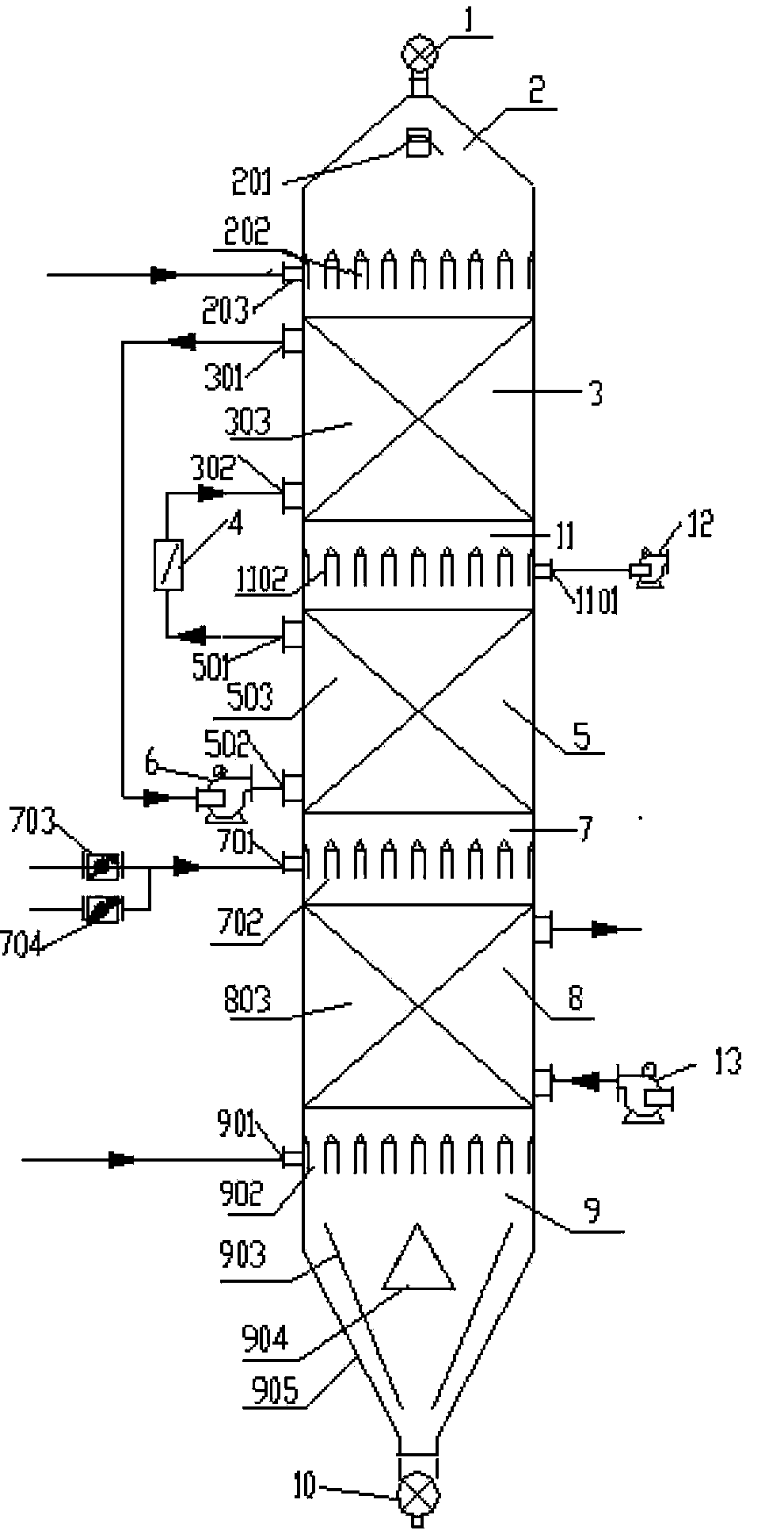

[0044] figure 1 Example 1 Schematic diagram of the structure of a desulfurization and denitrification active coke regeneration device. Such as figure 1 As shown, a desulfurization and denitrification active coke regeneration device proposed in this embodiment includes a regeneration reactor, and the regeneration reactor consists of an inlet air lock valve 1, a feed bin 2, a heating bin 3, and a regeneration bin 11. The pre-cooling bin 5, the cooling bin 8, the discharge bin 9 and the outlet air lock valve 10 are sequentially connected, and a heating heat exchanger assembly 303 for heating the heating bin 3 is arranged in the heating bin 3. In the pre-cooling bin 5 is provided with a pre-cooling heat exchanger assembly 503 for cooling the pre-cooling bin 5, and a cooling heat exchanger assembly 803 for cooling the cooling bin 8 is arranged in the cooling bin 8. Between the pre-cooling bin 5 and the cooling Between the bins 8, there is also a nitrogen loading bin 7 for introdu...

Embodiment 2

[0062] Figure 11 It is a schematic structural diagram of the desulfurization and denitrification active coke regeneration device in Example 2. Such as Figure 11 As shown, the difference between the present embodiment and the first embodiment is that the desulfurization and denitrification active coke regeneration device of the present embodiment adopts the hot blast stove as the desorption heat source, that is, the heating device 4 of the present embodiment adopts the hot blast stove instead of the one in the first embodiment Electric heaters. In this embodiment, the heating device is adjusted, and a part of the cooling air is used as the combustion-supporting air of the hot blast stove to generate high-temperature hot air, which is mixed with the heat exchange medium from the outlet of the cooling gas. Heating, reaching the desorption temperature for circulation, and the heat exchange medium is flue gas with an oxygen content below 3%. For other specific structures and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com