An Online Prediction Method of Concentrate Production

A forecasting method and mine production technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as immutability, prediction model not updated in real time, unreasonable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

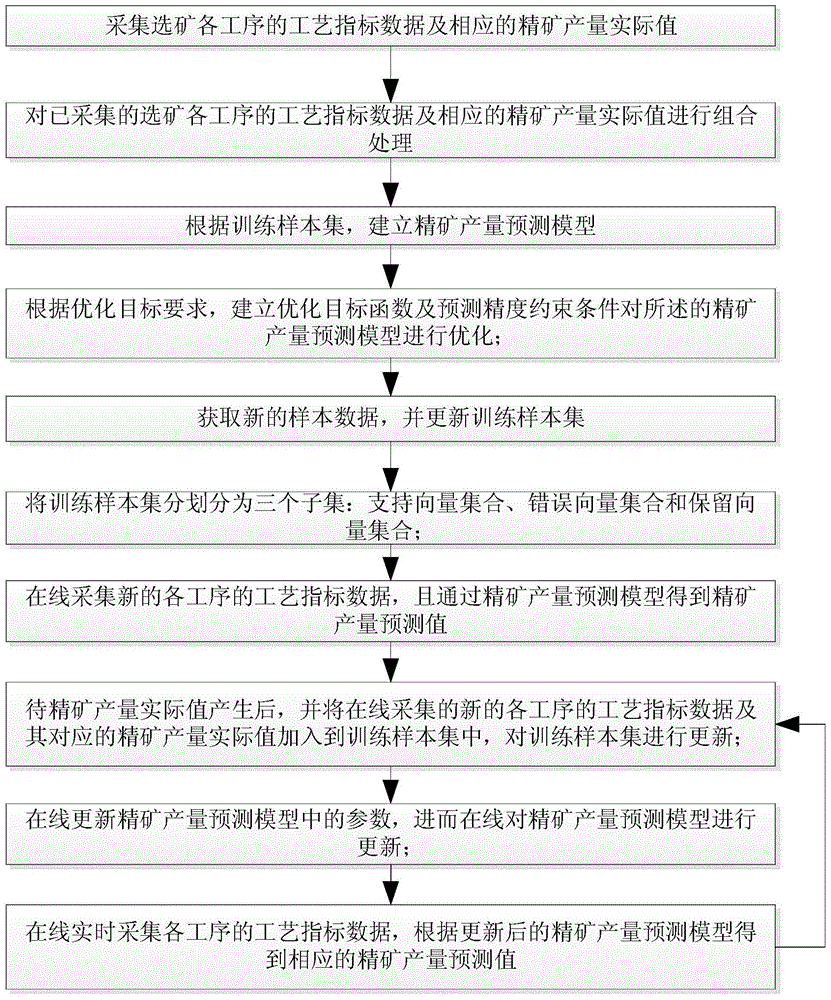

[0056] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

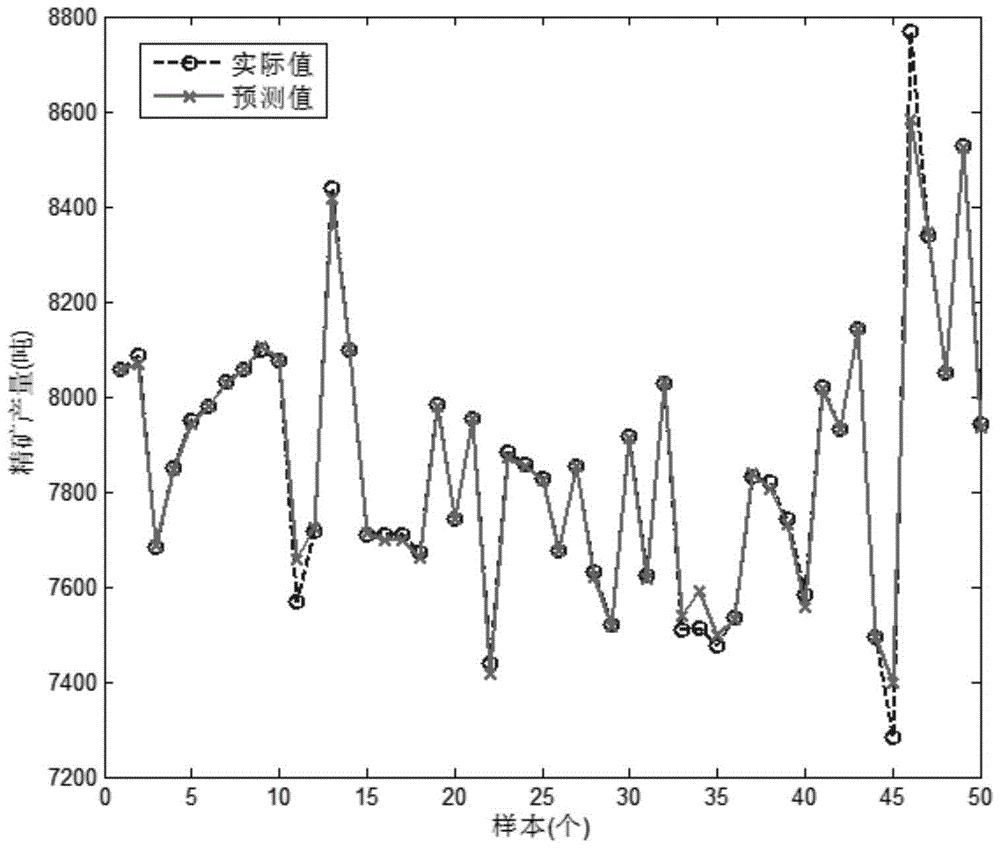

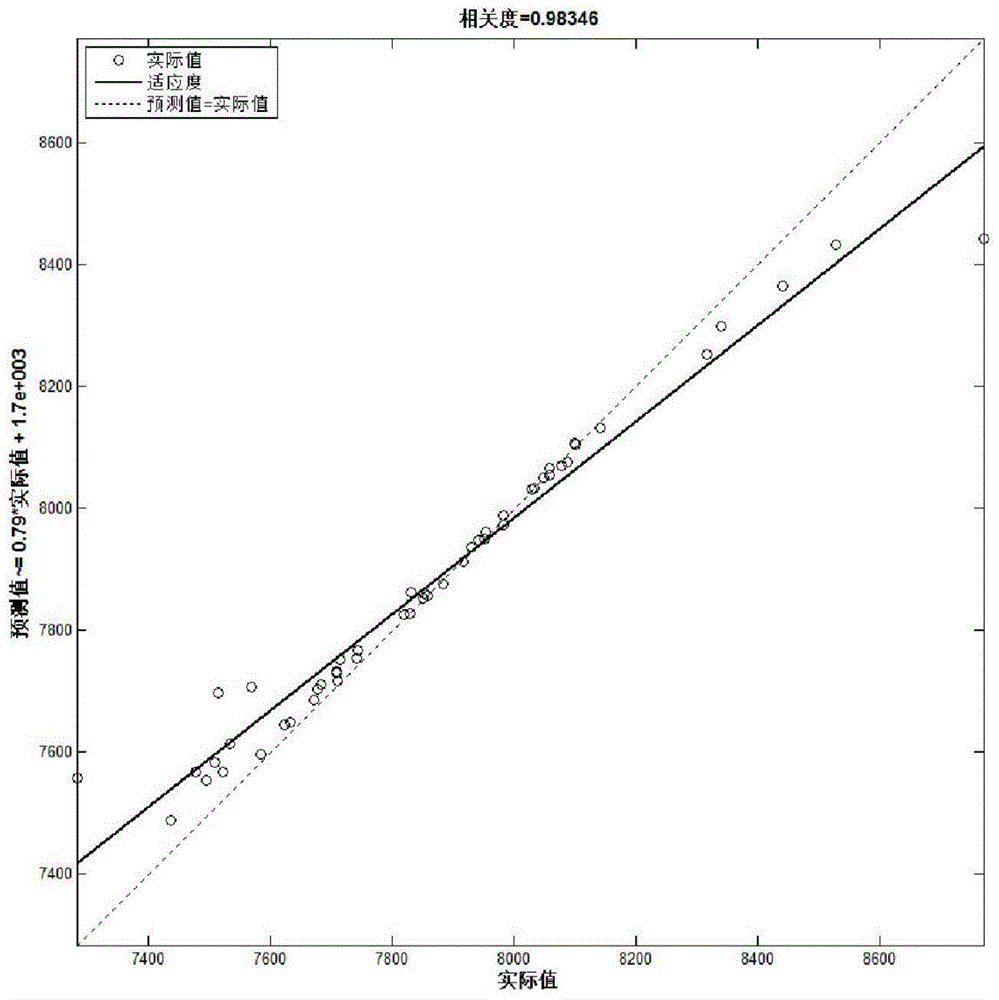

[0057] The method for online prediction of concentrate output in this embodiment is to predict concentrate output based on 170 sets of process index data and 14 process indexes of a certain mineral processing plant for 8 months in total. Among them, 14 process indicators are: primary overflow recovery rate, strong magnetic grinding particle size, weak magnetic grinding particle size, strong magnetic concentrate grade, weak magnetic concentrate grade, strong magnetic tailings grade, weak magnetic tailings grade, Weak magnetic grade, strong magnetic grade, high magnetic ball mill processing capacity, weak magnetic ball mill processing capacity, waste rock grade, high magnetic ball mill running time and weak magnetic ball mill running time; Select 120 groups in the process index data for combined processing, as shown in Table 1, select 50 groups of qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com