Flexible, temperature-resistant and environment-friendly fiber and preparation technology thereof

A preparation process and temperature-resistant technology, applied in the fiber field, can solve the problems of reduced mechanical properties, difficulty in obtaining, and limited low-temperature resistance, and achieve excellent mechanical properties, environmental protection in the preparation process, and good balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

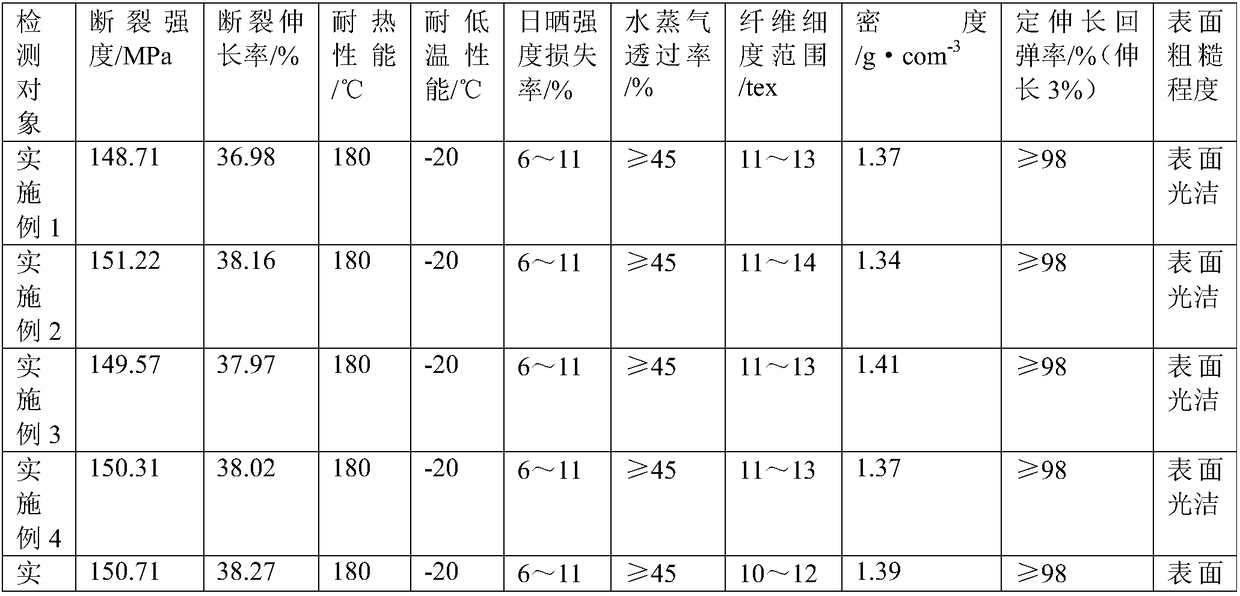

Examples

Embodiment 1

[0052] A preparation process of flexible temperature-resistant and environmentally friendly fibers, the preparation process comprising the following preparation steps:

[0053] 1) The processing and preparation of pineapple superfine powder suspension:

[0054] a) Pineapple is placed in an ultrafine pulverizer for ultrafine pulverization, and the pulverization time is 15 minutes to obtain pineapple superfine powder, and the mesh number of pineapple superfine powder is 200 mesh;

[0055] b) Adding 10% casein solution to the pineapple superfine powder obtained in step a), the weight of the added 10% casein solution is 75% of the weight of pineapple, to obtain a mixture;

[0056] c) adding an appropriate amount of water to the mixture obtained in step b) to prepare a pineapple superfine powder suspension;

[0057] 2) Dissolving the ultra-high molecular weight polyethylene powder in a small molecule alkane solvent, preparing a dilute solution, and stirring the dilute solution, sl...

Embodiment 2

[0064] A preparation process of flexible temperature-resistant and environmentally friendly fibers, the preparation process comprising the following preparation steps:

[0065] 1) The processing and preparation of pineapple superfine powder suspension:

[0066] a) Pineapple is placed in an ultrafine pulverizer for ultrafine pulverization, and the pulverization time is 60 minutes to obtain pineapple superfine powder, and the mesh number of pineapple superfine powder is 350 mesh;

[0067] b) adding 10% casein solution to the superfine powder of pineapple hemp obtained in step a), the weight of the added 10% casein solution is 80% of the weight of pineapple hemp to obtain a mixture;

[0068] c) adding an appropriate amount of water to the mixture obtained in step b) to prepare a pineapple superfine powder suspension;

[0069] 2) Dissolving the ultra-high molecular weight polyethylene powder in a small molecule alkane solvent, preparing a dilute solution, and stirring the dilute ...

Embodiment 3

[0076] A preparation process of flexible temperature-resistant and environmentally friendly fibers, the preparation process comprising the following preparation steps:

[0077] 1) The processing and preparation of pineapple superfine powder suspension:

[0078] a) Pineapple is placed in an ultrafine pulverizer for ultrafine pulverization, and the pulverization time is 30 minutes to obtain pineapple superfine powder, and the mesh number of pineapple superfine powder is 250 mesh;

[0079] b) Adding 10% casein solution to the pineapple superfine powder obtained in step a), the weight of the added 10% casein solution is 75% of the weight of pineapple, to obtain a mixture;

[0080] c) adding an appropriate amount of water to the mixture obtained in step b) to prepare a pineapple superfine powder suspension;

[0081] 2) Dissolving the ultra-high molecular weight polyethylene powder in a small molecule alkane solvent, preparing a dilute solution, and stirring the dilute solution, sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com