Electromagnetic wave shielding breathable porous carbon composite material and preparation method and application thereof

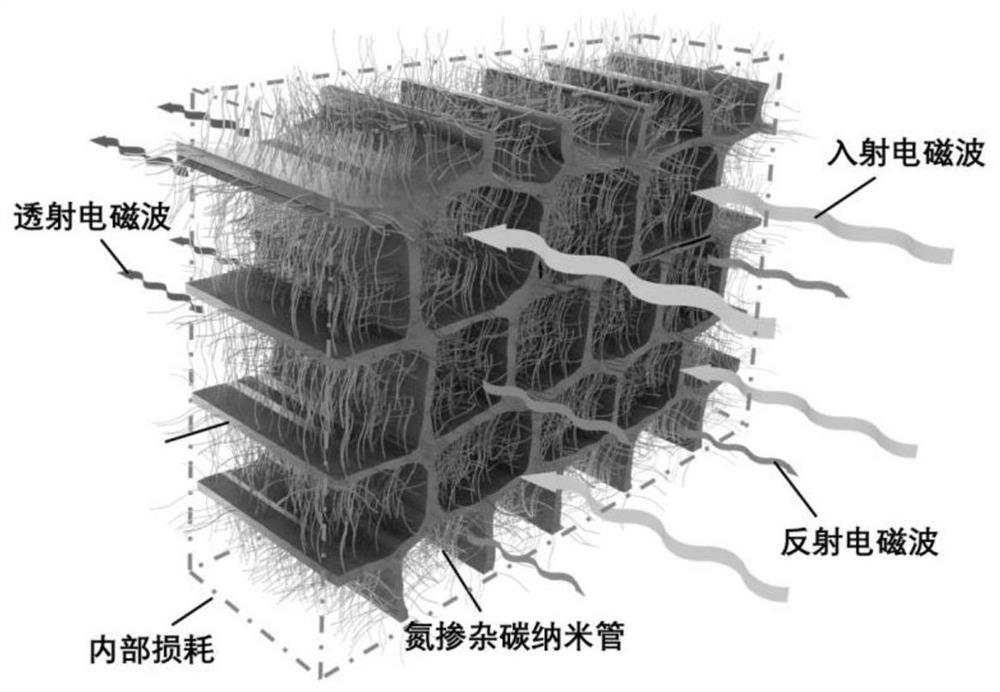

A composite material, porous carbon technology, applied in the fields of magnetic field/electric field shielding, electrical components, nanotechnology for materials and surface science, etc. Short cycle, excellent heat dissipation performance, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

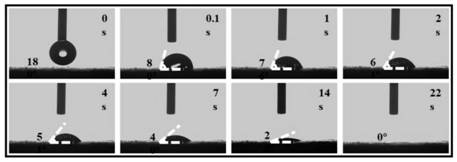

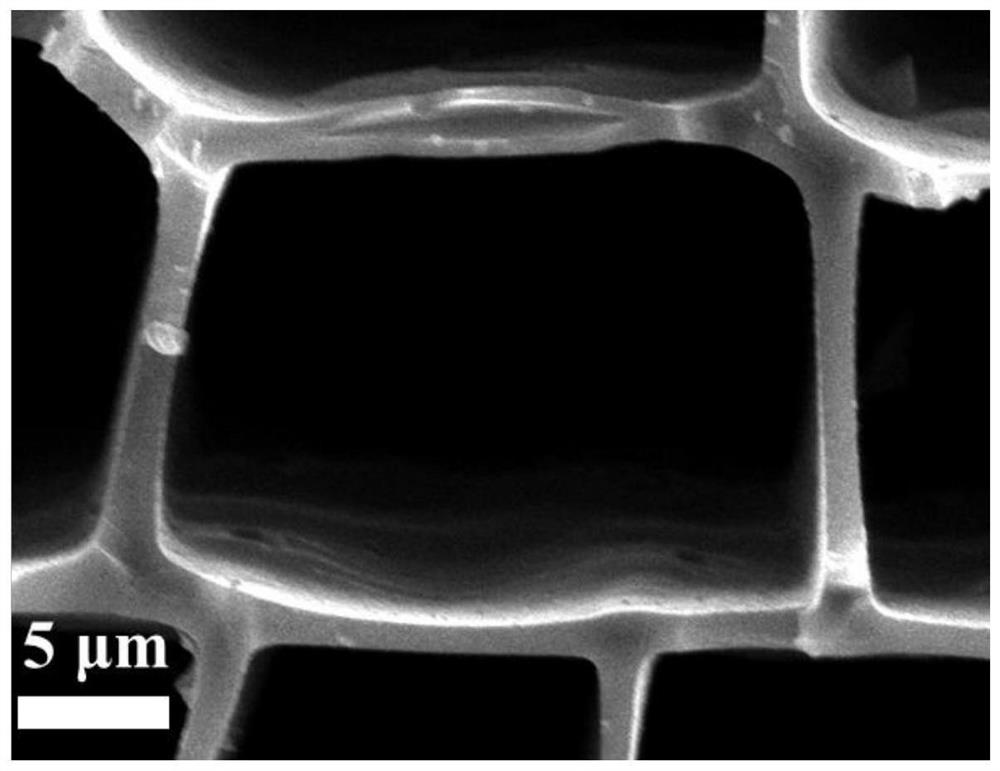

[0047] (1) Cut the natural Chinese fir along the direction perpendicular to the growth direction to obtain fir wood blocks. First, pre-carbonize the fir wood blocks at 500°C for 2 hours at a medium temperature, and then carry out high-temperature carbonization at 900°C for 3 hours. The carbonized wood obtained by carbonization step by step The block was sanded to a suitable size, washed with ethanol and deionized water and dried to obtain a carbonized wood block (denoted as CW); its SEM image is shown in figure 2 As shown, it can be seen from the figure that there are a large number of vertical channels in carbonized wood, and the diameter of the channels is between 10 and 10 μm.

[0048] (2) Immerse the carbonized wood block in Ni 2+ In solution, Ni 2+ The solution uses ethylene glycol as a solvent, and includes the following concentrations of components: polyvinylpyrrolidone 0.1 g / mL, Ni(NO 3 ) 2 ·6H 2 O 1.5 mol / L; take it out, and dry it at 100°C for 20 hours to get Ni...

Embodiment 2

[0052] (1) Cut the natural Chinese fir along the direction perpendicular to the growth direction to obtain fir wood blocks. First, pre-carbonize the fir wood blocks at 200°C for 3 hours at a medium temperature, and then carry out high-temperature carbonization at 800°C for 5 hours. The blocks were sanded to a suitable size, washed with ethanol and deionized water and dried to obtain carbonized wood blocks;

[0053] (2) Immerse the carbonized wood block in Ni 2+ In solution, Ni 2+ The solution uses ethylene glycol as the solvent, and includes the following components: polyvinylpyrrolidone 0.05 g / mL, nickel acetate 1.0 mol / L, nickel chloride 1.0 mol / L; take it out, dry it at 60°C for 24 hours, and get the adsorbed Ni 2+ carbonized wood blocks;

[0054] (3) Place the carbonized wood blocks treated in step (2) and dicyandiamide at intervals, the mass ratio of dicyandiamide to carbonized wood blocks is 5:1; feed nitrogen, and dicyandiamide is located upstream of the argon flow, ...

Embodiment 3

[0056] (1) Cut the natural Chinese fir along the direction perpendicular to the growth direction to obtain fir wood blocks. First, pre-carbonize the fir wood blocks at 400°C for 1 hour at a medium temperature, and then carry out high-temperature carbonization at 1000°C for 2 hours. The blocks were sanded to a suitable size, washed with ethanol and deionized water and dried to obtain carbonized wood blocks;

[0057] (2) Immerse the carbonized wood block in Ni 2+ In solution, Ni 2+ The solution uses ethylene glycol as the solvent, and includes the following components: polyvinylpyrrolidone 0.15 g / mL, nickel sulfate 0.1 mol / L; take it out, and dry it at 120°C for 12 hours to obtain the adsorbed Ni 2+ carbonized wood blocks;

[0058] (3) Place the carbonized wood blocks treated in step (2) and dicyandiamide at intervals, and the mass ratio of dicyandiamide to carbonized wood blocks is 20:1; feed nitrogen, and dicyandiamide is located at the upstream of the argon flow, Carry out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com