Patents

Literature

35results about How to "Production conditions are easy to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

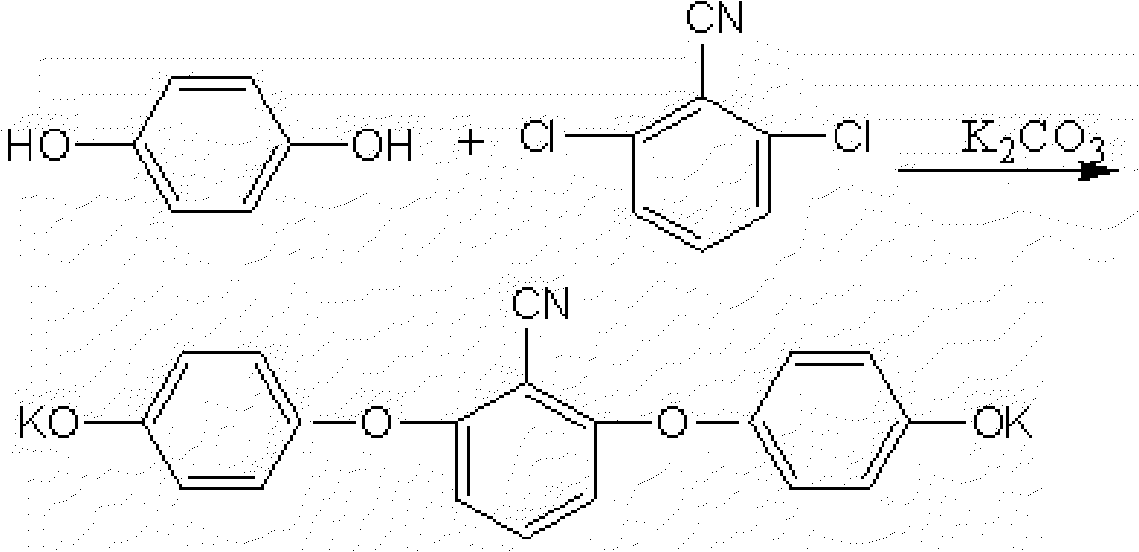

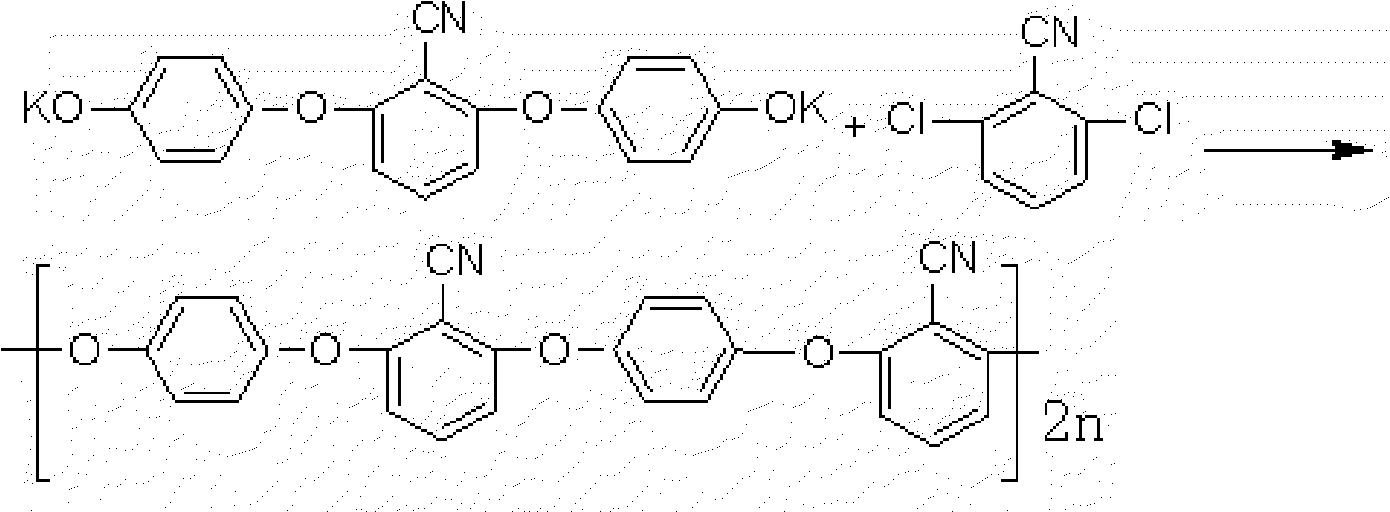

Method for preparing poly(arylene ether nitrile) resin

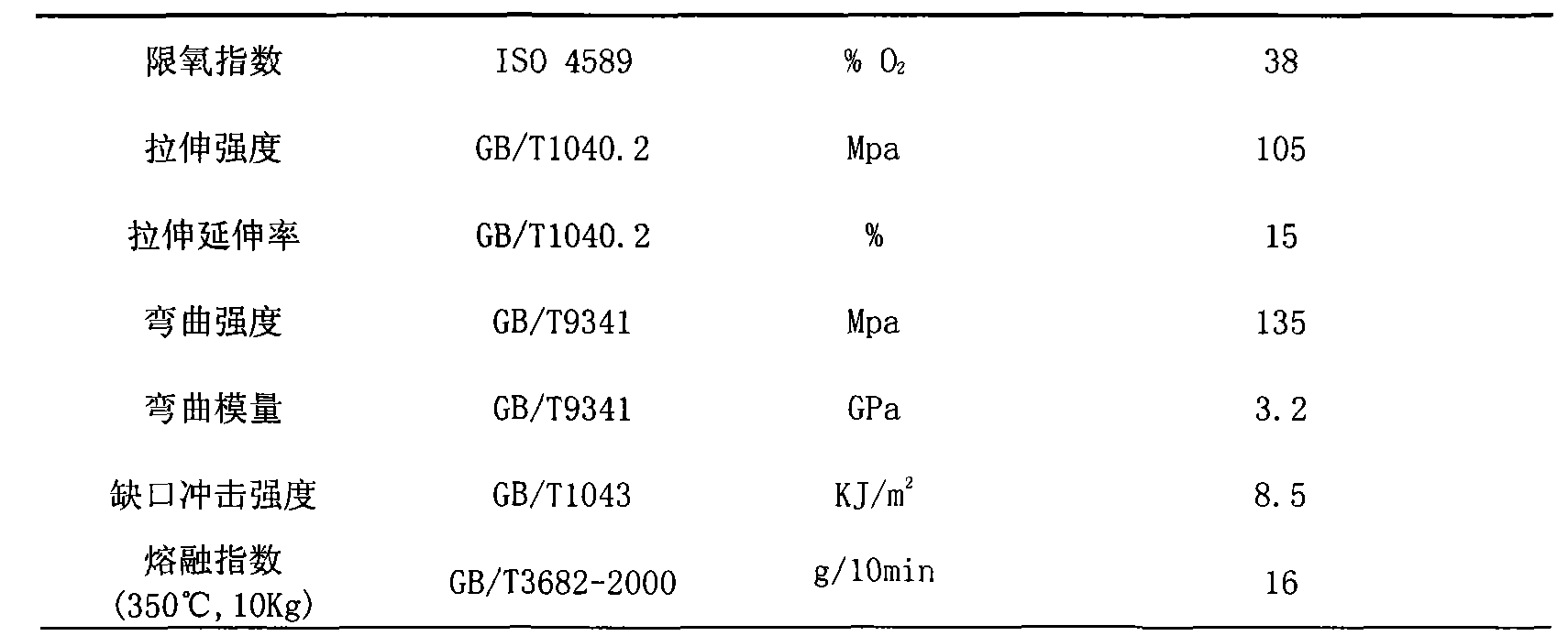

The invention discloses a method for preparing poly(arylene ether nitrile) resin, which belongs to the technical field of high polymer materials. The method comprises the following steps of: finishing a reaction in a reaction kettle under normal pressure under the actions of a catalyst and a dehydrating agent by taking 2,6-dichlorobenzonitrile and aromatic dicarboxylic phenol as raw materials and taking N-methyl pyrrolidone as a solvent; pressurizing and atomizing solution after dilution to a precipitating agent for precipitating; after heating, stirring and refluxing a precipitate and the precipitating agent to finish solvent extraction, performing solid-liquid separation by using a centrifugal machine; allowing liquid to enter a rectifying tower for rectifying and recovering the solvent; and drying solid after washing with boiling water to obtain the poly(arylene ether nitrile) resin of the invention. The method has the characteristics of easily implemented production conditions, and safe and environmentally-friendly production process. The poly(arylene ether nitrile) resin prepared by adopting the method of the invention has the characteristics of high purity and stable performance, and can be applied to the field of aerospace, electronics, machinery, medical treatment, chemical industry and the like.

Owner:SICHUAN FEIYA NEW MATERIAL

Polyarylether carbonitrile industrial production method

The industrial process of polyarylethernitrile, this invention relates to the Synthesis of polyarylethernitrile. Adding 2, 6-dichlorocyanobenzene, polyhydric phenol, anhydrous potassium carbonate, solvent NMPA, toluene in autoclave, heating-up the autoclave to 100-200 deg C in the condition of 2. 0-2. 5MPa in autoclave, heating-up the autoclave to 150-300deg C after 2-6h heat preservation, taking out the fixed object of autoclave after 1-6h heat preservation, getting the polyarylethernitrile after washing by boiling-water, desiccation and granulation. The production condition of this invention is easy to realize, the industrial process is easy to control, and the produced polyarylethernitrile is low in cost and suit to use of multirealm.

Owner:YANGZHOU TIANCHEN FINE CHEM

Industrial production method of semi-crystalline poly aryl ether nitrile

The invention relates to an industrial production method for semi-crystal poly(aromatic ether nitrile), which belongs to the field of polymer material. The method comprises the following steps: 2, 6-dichloro benzonitrile and hydroquinone are taken as raw materials; anhydrous potassium carbonate is taken as a catalyst; in the presence of a solvent and a dehydrating agent, the raw materials and the catalyst react under atmospheric pressure to obtain the poly(aromatic ether nitrile) homopolymer with low molecular weight and regular chain segments; and then the molecular weight of polymer is increased through pressurization, so as to obtain the semi-crystal poly(aromatic ether nitrile) polymer with high molecular weight. Due to the increase of crystallinity and molecular weight, the mechanical properties and heat resistance of the semi-crystal poly(aromatic ether nitrile) polymer are obviously improved.

Owner:SICHUAN FEIYA NEW MATERIAL

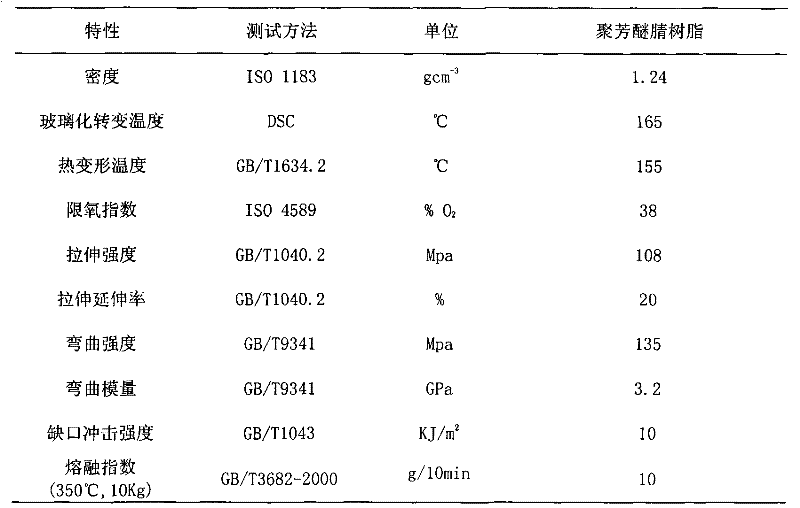

Polyaryl ether nitrile resin and industrialized synthetic method thereof

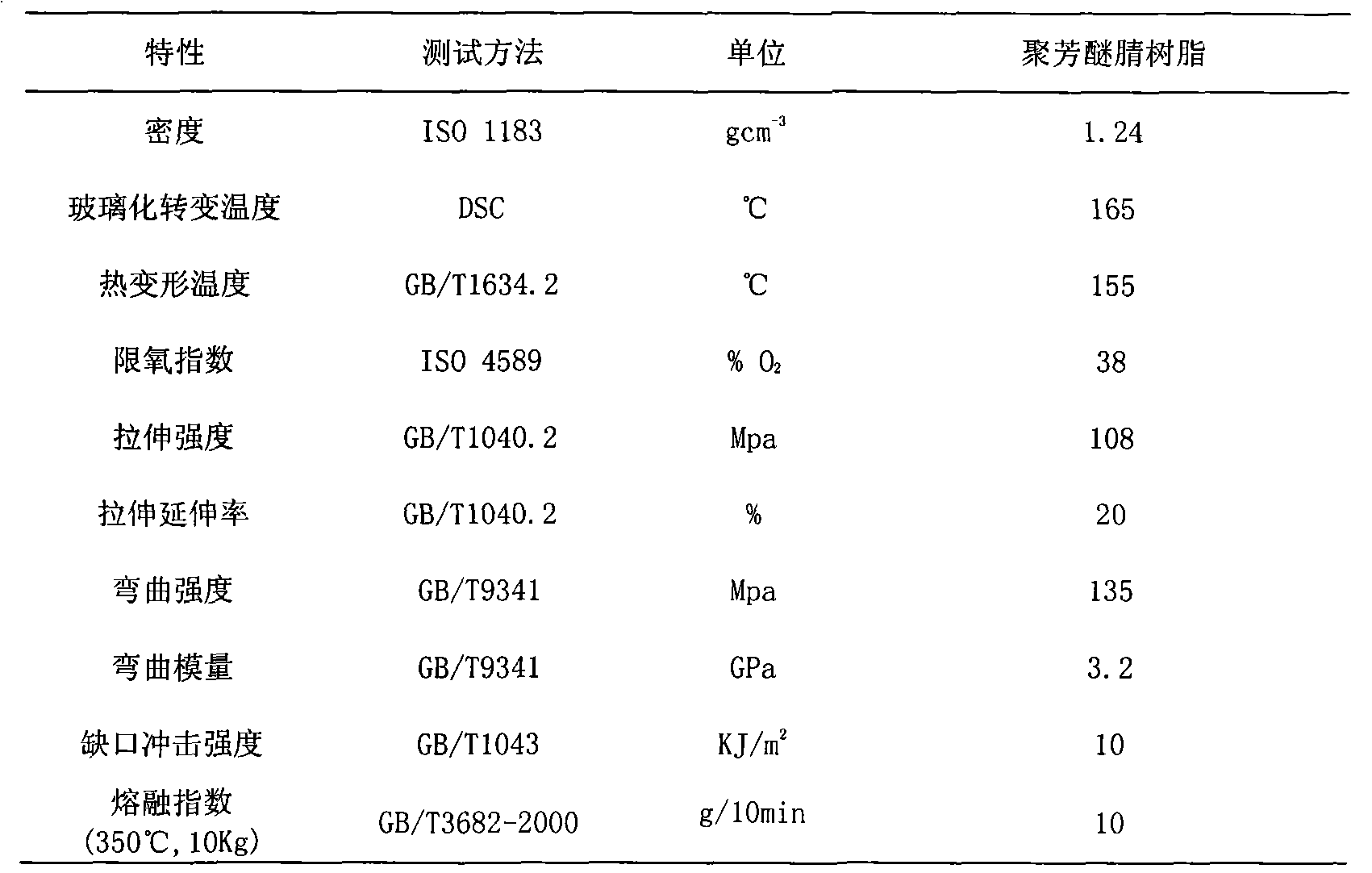

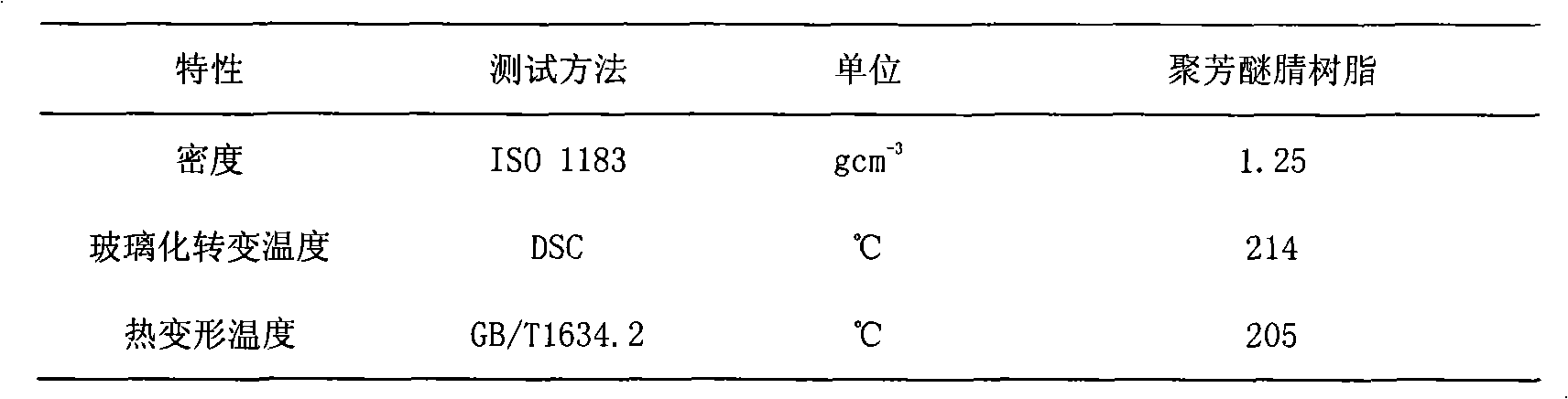

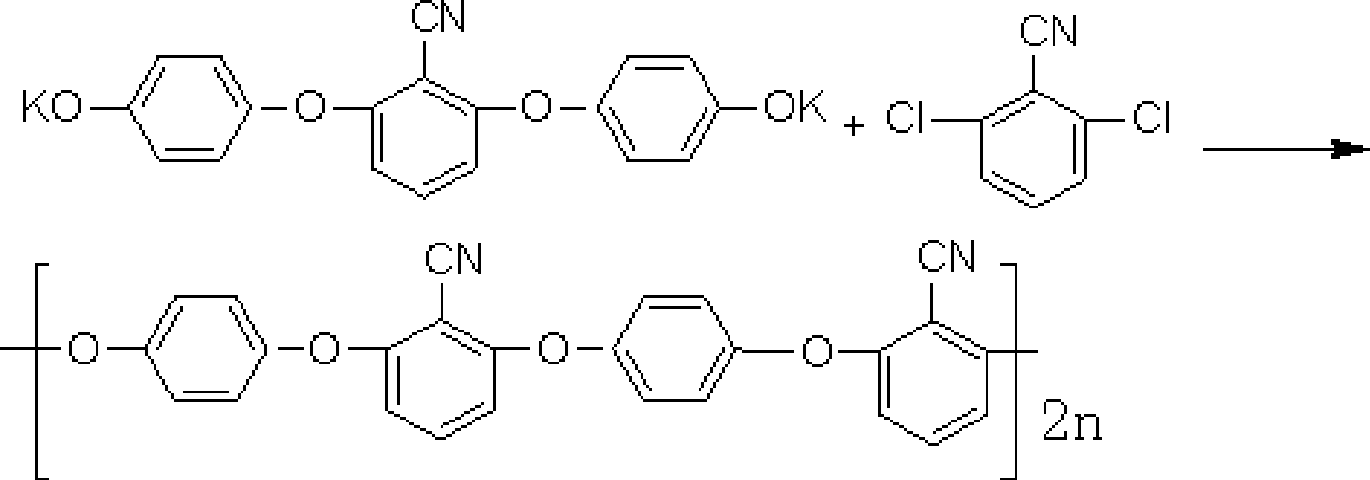

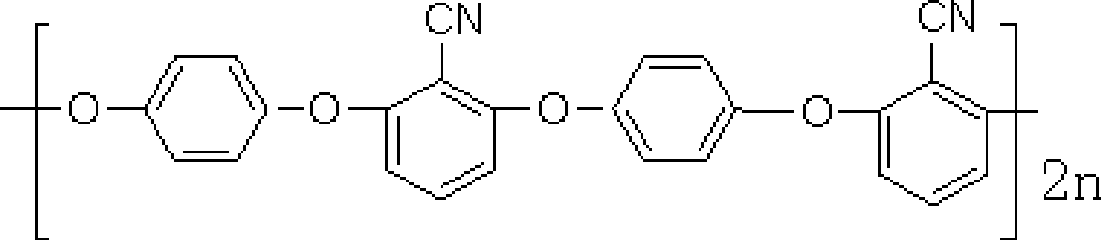

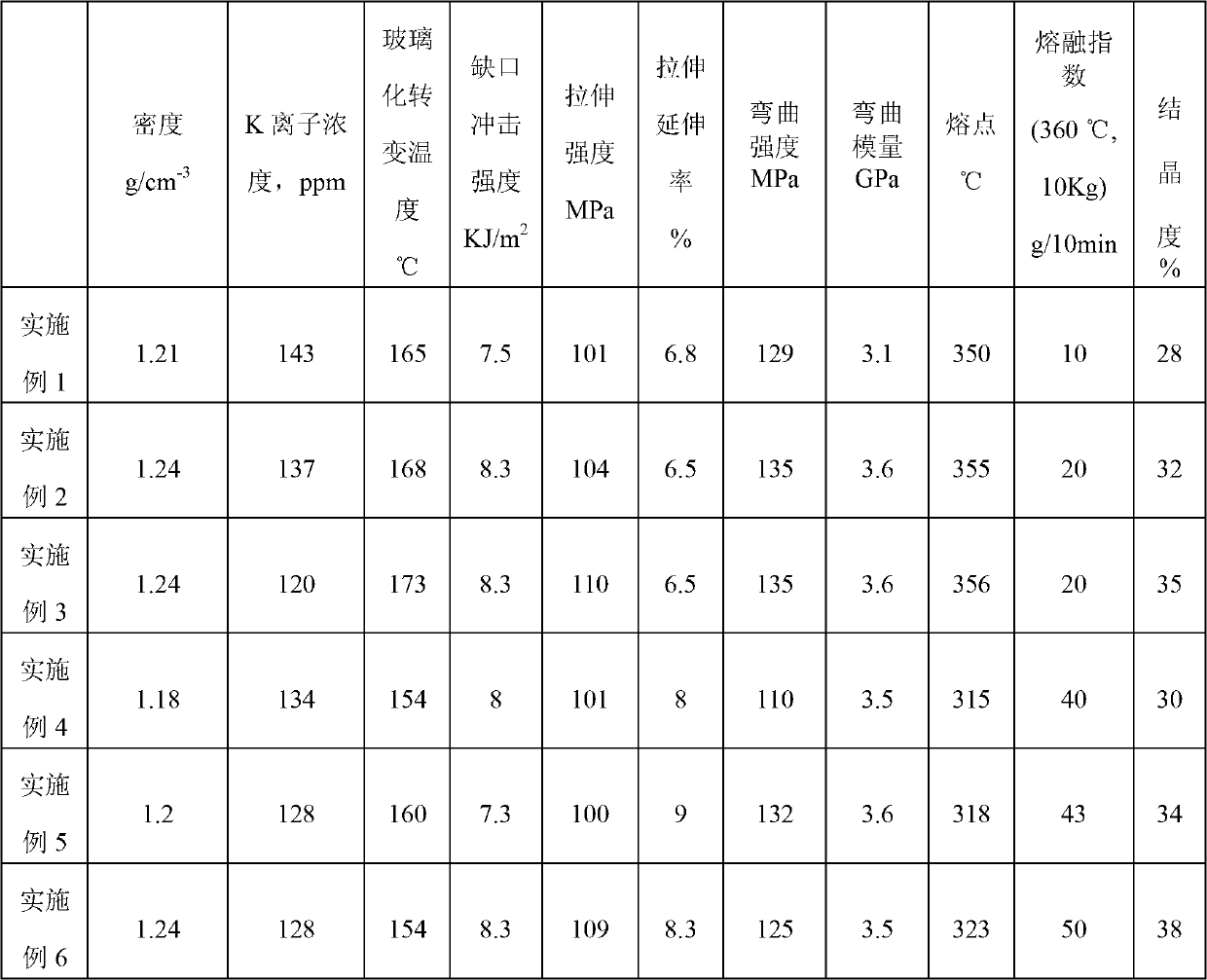

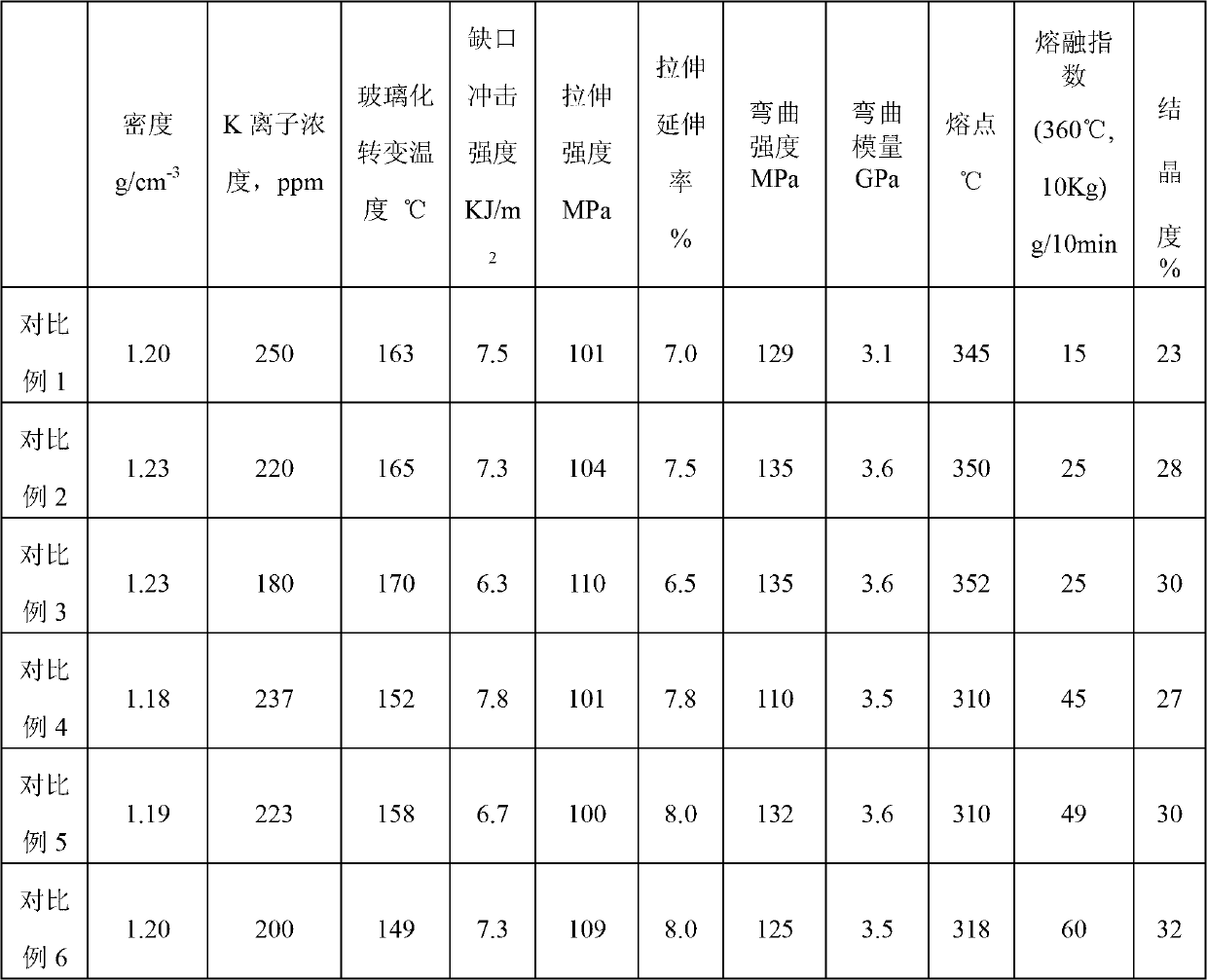

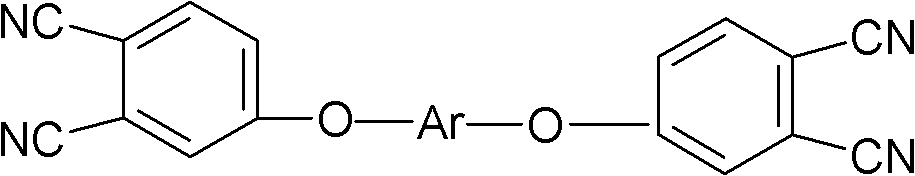

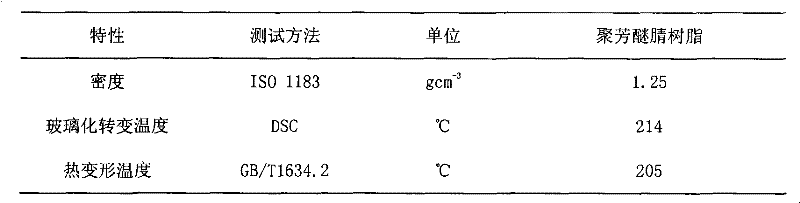

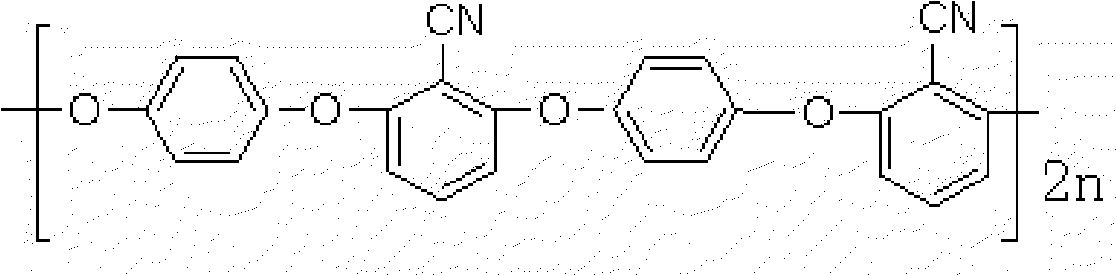

The invention belongs to the technical field of polymer materials, and especially relates to a polyaryl ether nitrile resin and an industrialized synthetic method thereof. The structural unit of the polyaryl ether nitrile resin is one of units shown in the specification, and the crystallinity degree of the polyaryl ether nitrile resin is 28-38%. The polyaryl ether nitrile resin prepared by the invention is high in purity and high in crystallinity degree (28-38%); the glass transition temperature is 150-180 DEG C, the melting point is 310-355 DEG C, and the initial decomposition temperature is more than 450 DEG C; the resin has higher mechanical strength, the tensile strength is 100-120Mpa, the tensile modulus is 2.4-3.6GPa, and the bending strength is 100-140Mpa; and therefore, the polyaryl ether nitrile resin prepared by using the method disclosed by the invention can be applied to the fields such as aerospace, electronics, machinery, medical treatment, chemical engineering and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

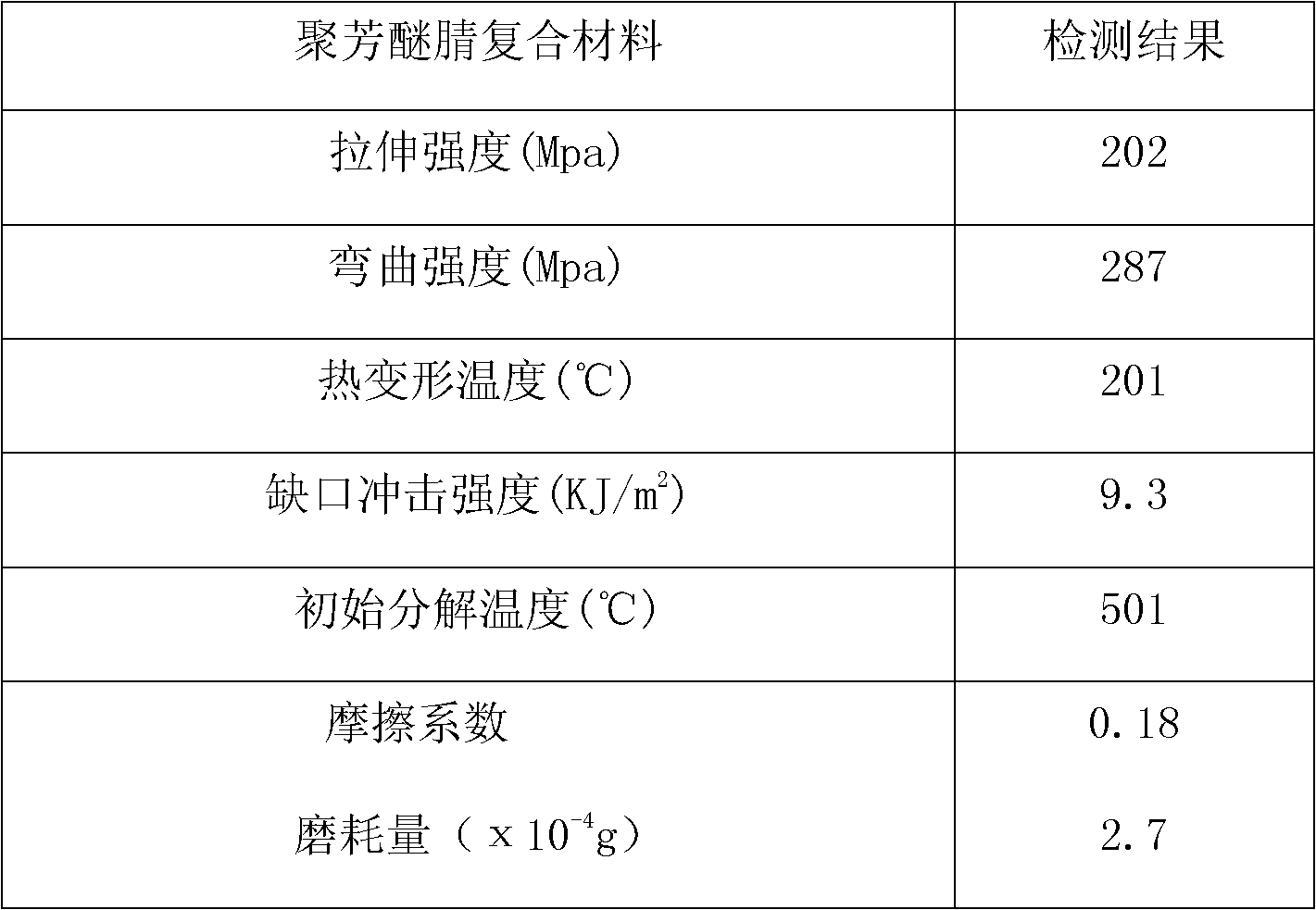

Poly (arylene ether nitrile) composite material and preparation method thereof

ActiveCN101891947AProduction conditions are easy to achieveThe production process is easy to controlFiberPolymer science

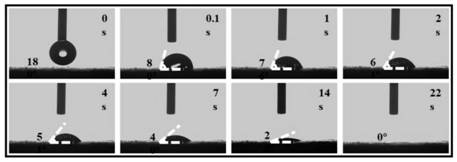

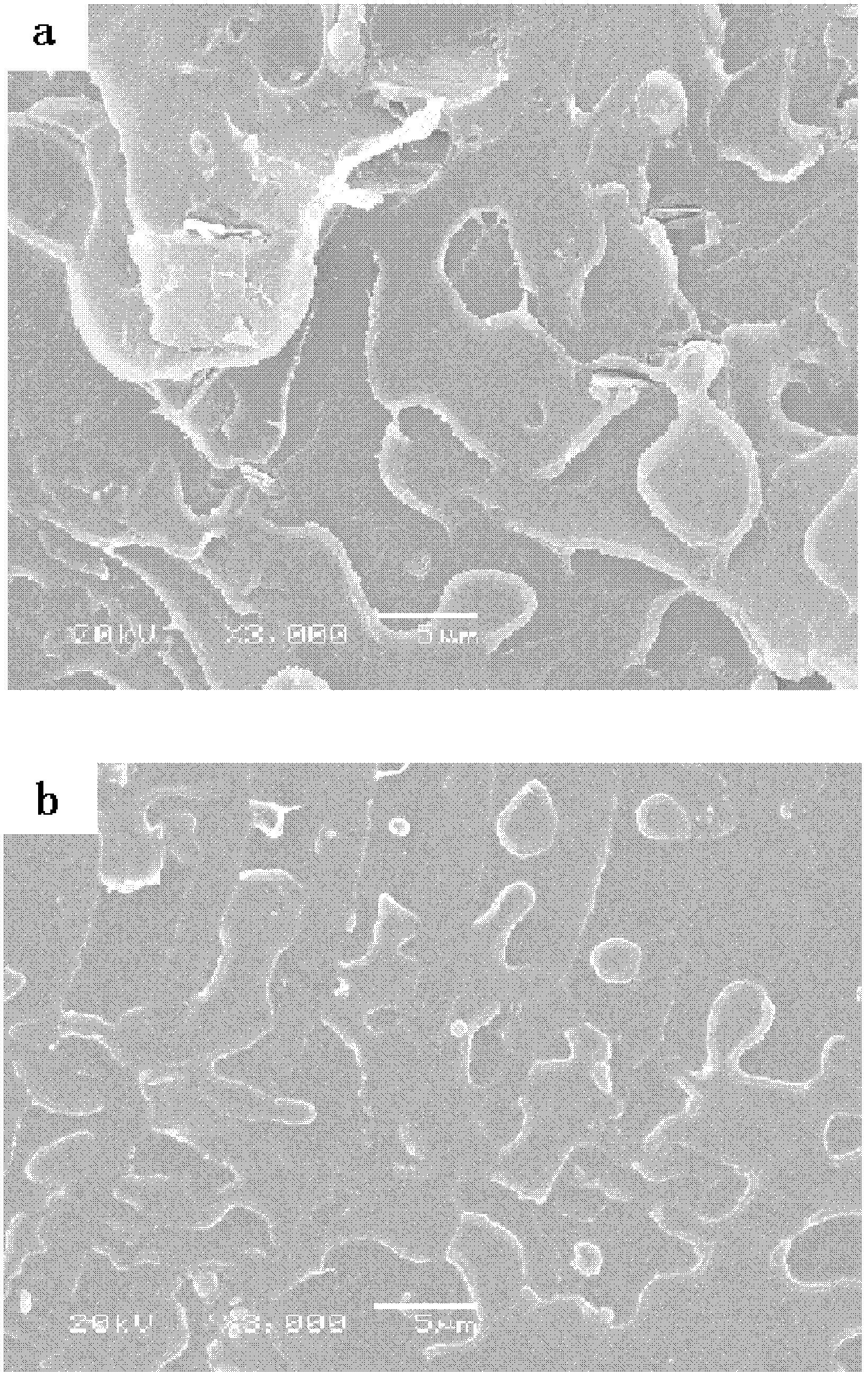

The invention belongs to the field of high polymer materials, particularly relating to a poly (arylene ether nitrile) composite material and a preparation method thereof. The invention aims to solve the first technical problem of providing the poly (arylene ether nitrile) composite material with high performance and wear resistance. The poly (arylene ether nitrile) composite material of the invention comprises the following components in parts by weight: 40-70 parts of poly (arylene ether nitrile), 10-40 parts of filling, 3-10 parts of phthalocyanine prepolymer and 0-7 parts of anti-wear additive. The phthalocyanine prepolymer of the invention has the effect of plastification and improve the interface action between a resin system and fibers and between the resin system and the anti-wear additive, and the mechanical strength, abrasive resistance and abrasive resistance of the composite material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

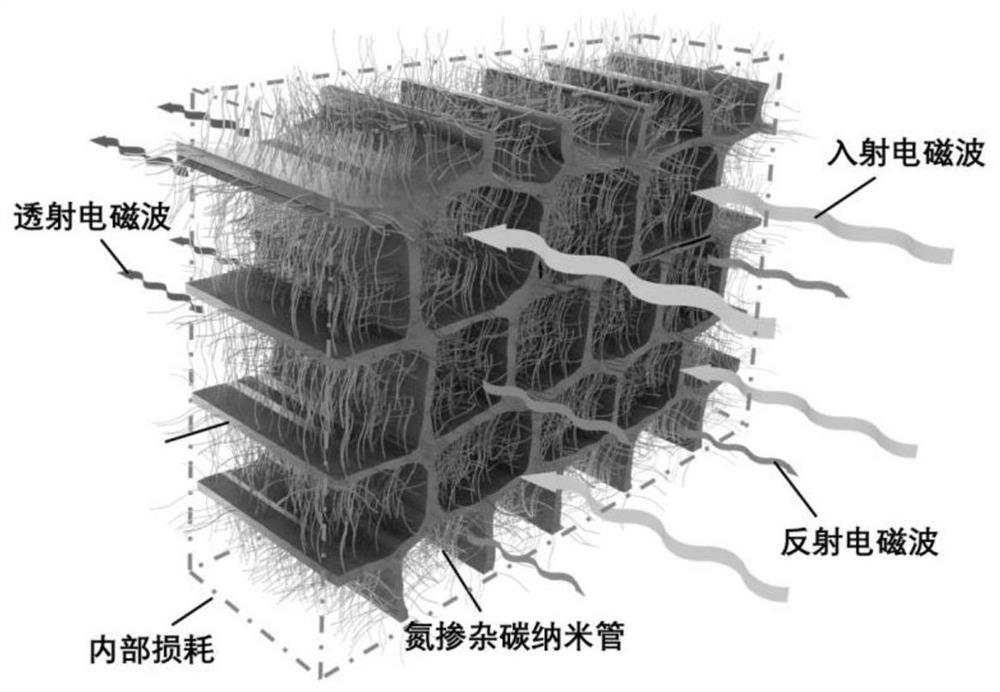

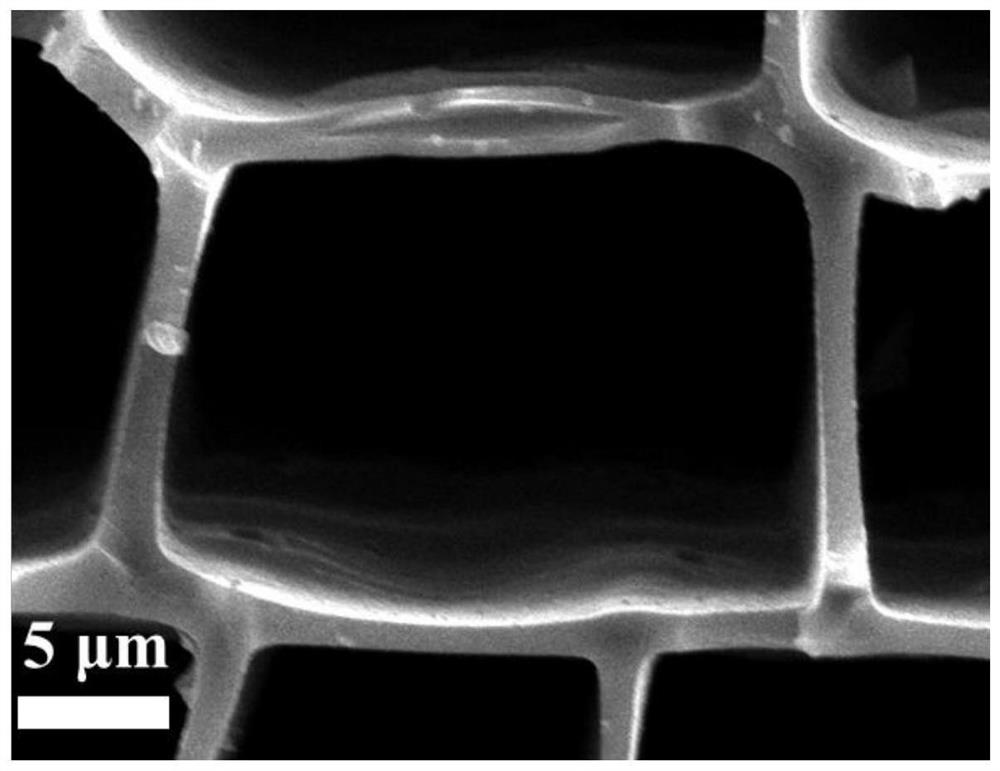

Electromagnetic wave shielding breathable porous carbon composite material and preparation method and application thereof

ActiveCN113271758AReduce manufacturing costAbundant and renewable sourcesMaterial nanotechnologyMagnetic/electric field screeningPorous carbonCarbonization

The invention relates to the technical field of electromagnetic shielding, in particular to an electromagnetic wave shielding breathable porous carbon composite material and a preparation method and application thereof. The preparation method comprises the following steps: 1, enabling a wood block to be subjected to medium-temperature pre-carbonization and then subjected to high-temperature carbonization, and obtaining a carbonized wood block; (2) dipping the carbonized wood block in a Ni2+ solution, taking out the carbonized wood block and drying the carbonized wood block; (3) placing the carbonized wood block and dicyandiamide at an interval, introducing nitrogen, performing heating in different temperature zones, growing nitrogen-doped carbon nanotubes on the carbonized wood blocks adsorbed with Ni2+ in situ, and obtaining the nickel@nitrogen-doped carbon nanotube / carbonized wood composite material. The Ni@NCNT / CW composite material prepared by adopting the method is light magnetic porous carbon, nitrogen-doped carbon nanotubes grow in situ in the Ni-coated NCNT / CW composite material, the Ni-coated NCNT / CW composite material shows electromagnetic wave shielding performance with main absorption, and the porous structure endows the material with good air permeability, good gas circulation and excellent heat dissipation performance.

Owner:HANGZHOU DIANZI UNIV

Preparation method for phytosterol acetate formed by catalytic synthesis through enzymic method

ActiveCN102703557ASimple production equipmentProduction conditions are easy to achieveFermentationOrganic solventPhytosterol

The invention relates to a preparation method for phytosterol acetate formed by catalytic synthesis through an enzymic method. The preparation method comprises the following steps: dissolving pyruvic acid and phytosterin as reaction substrates into dehydrated organic solvent; adding immobilized lipase and a dehydrating agent; and carrying out an oscillating reaction in a water bath of 40-60DEG C for 16-20 hours to obtain the phytosterol acetate, wherein the esterification rate is high as high as 93.01 percent. According to the preparation method disclosed by the invention, the phytosterol acetate is prepared from the pyruvic acid and the phytosterin as raw materials. The preparation method has the advantages of requirement on simple equipment, environment friendliness, safety and higher esterification rate.

Owner:SOUTH CHINA UNIV OF TECH

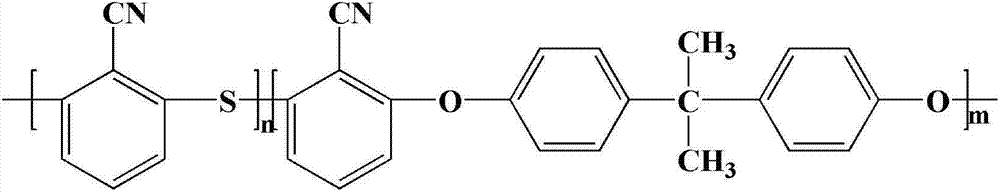

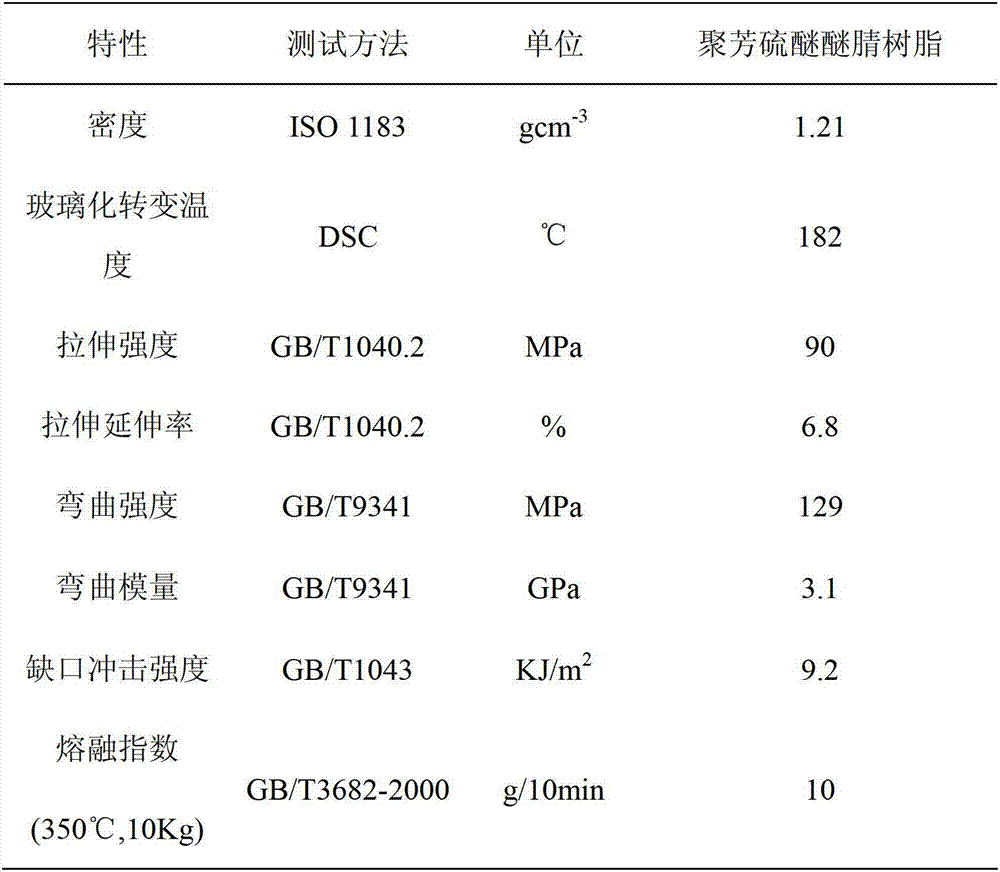

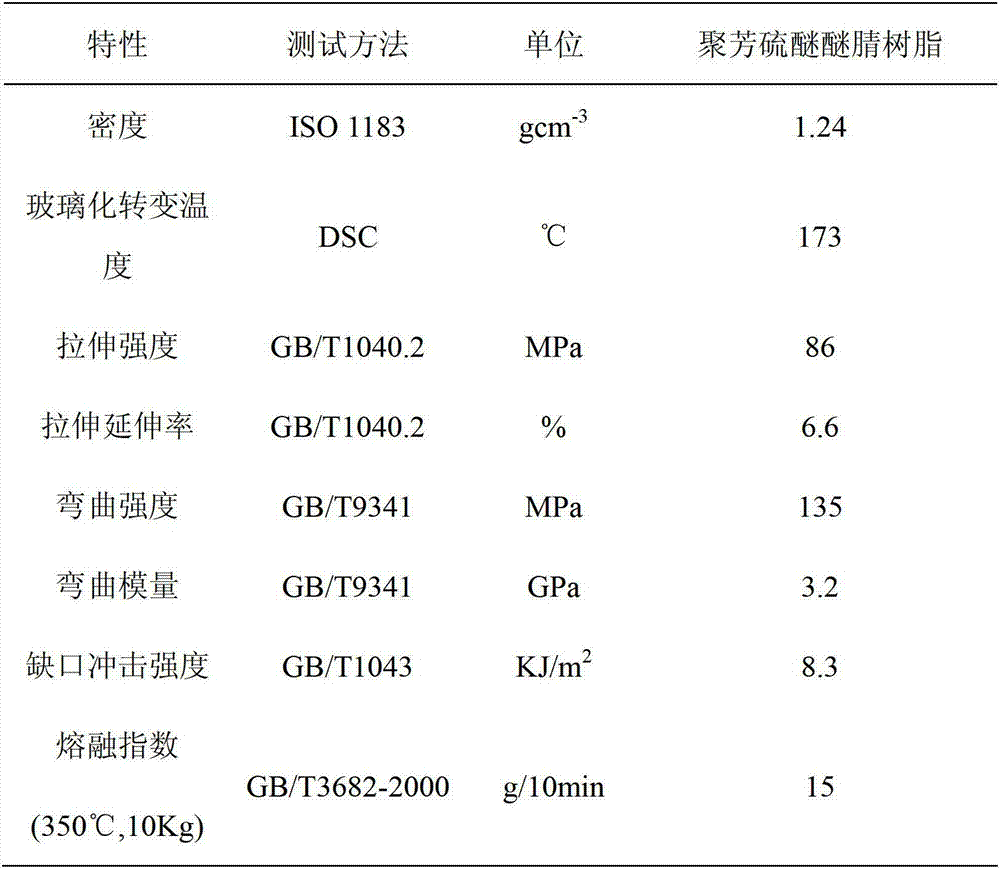

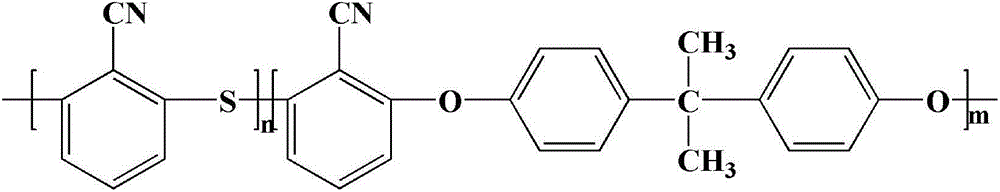

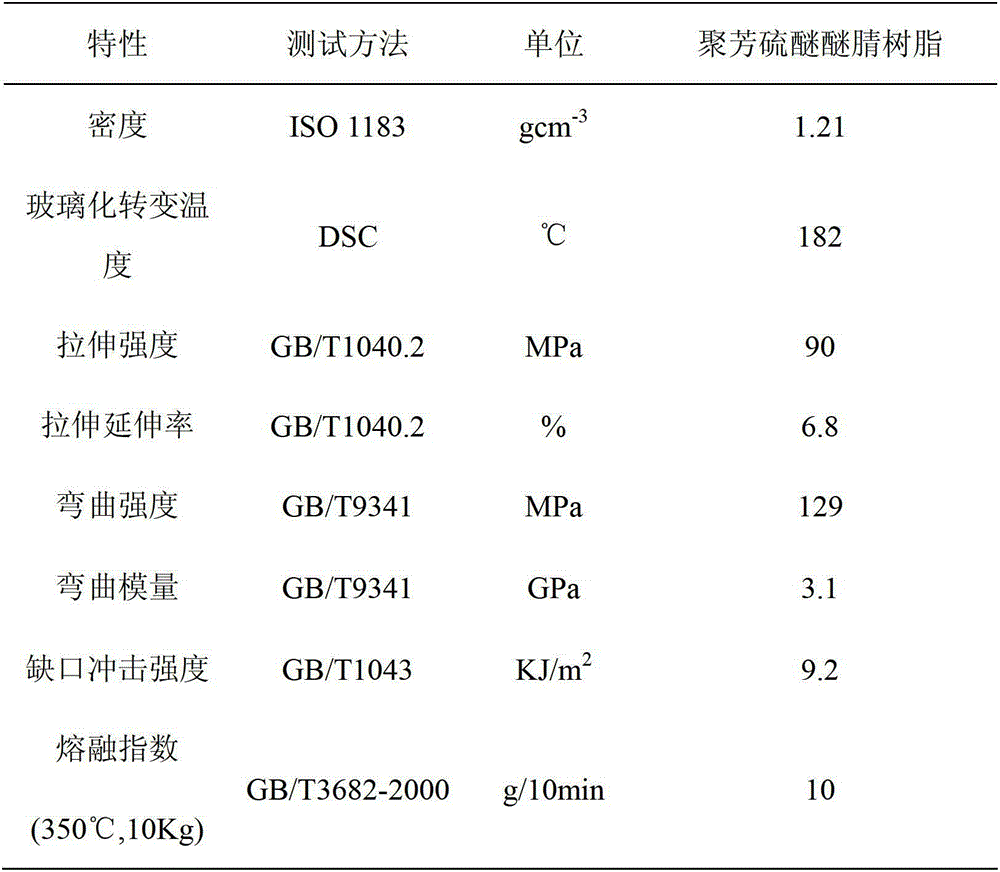

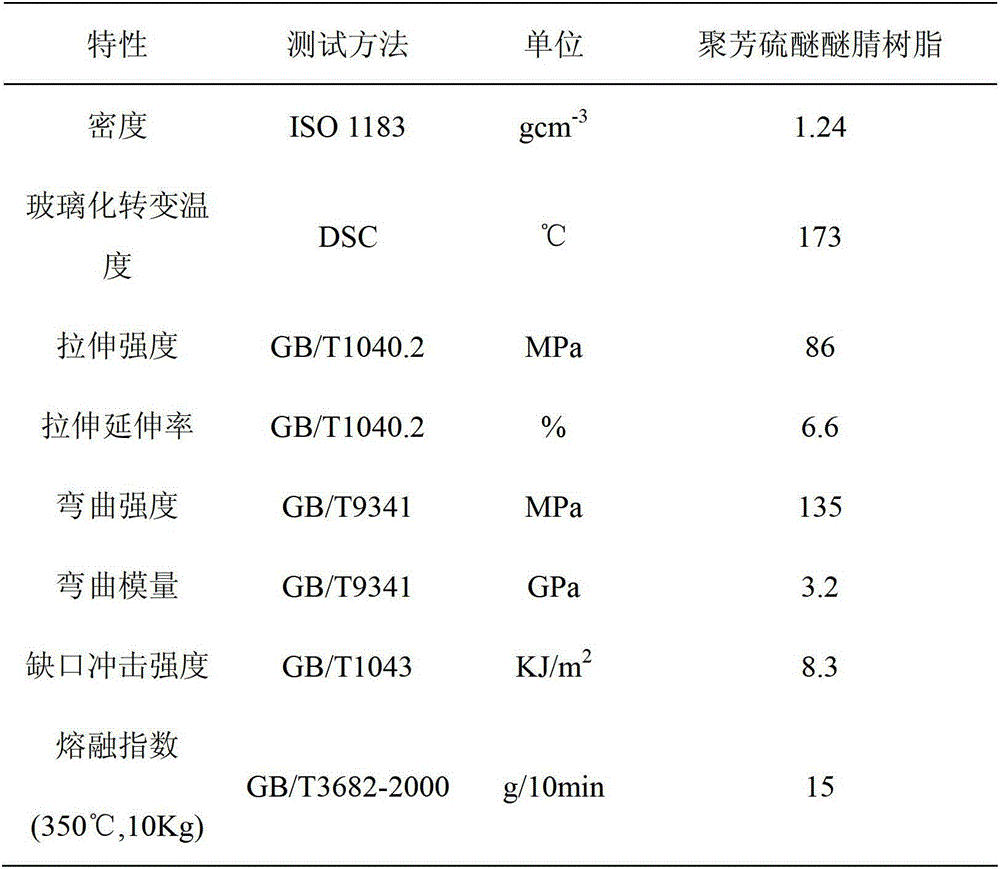

Bisphenol A type polyarylene sulfide ether nitrile resin and preparation method thereof

The invention provides a bisphenol A type polyarylene sulfide ether nitrile resin and a preparation method of the bisphenol A type polyarylene sulfide ether nitrile resin, belonging to the technical field of high polymer materials. The bisphenol A type polyarylene sulfide ether nitrile resin is prepared by carrying out normal-pressure reaction on 2,6-dichloro-cyanobenzene, sodium sulfide and bisphenol A as raw materials in N-methyl-pyrrolidone as solvent under the action of catalyst potassium carbonate and dehydrating agent toluene; precipitating the reaction solution through a precipitating agent, crushing the precipitate by a crushing machine to obtain particles, and grinding the particles in a colloid mill to obtain emulsified fine powder; and soaking the fine powder in organic solvent and carrying out solid-liquid separation through a centrifugal machine, entering the liquid to a rectifying tower for rectifying and recovering solvent, washing the solid with boiling water and drying to obtain the bisphenol A type polyarylene sulfide ether nitrile resin. The preparation method has the advantages that the production conditions are easy to realize and the production process is safe and environment-friendly; and the bisphenol A type polyarylene sulfide ether nitrile resin prepared by the preparation method is stable in performance and can be applied the fields such as aerospace and spaceflight, electronics, machinery, medical treatment and chemical industry.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

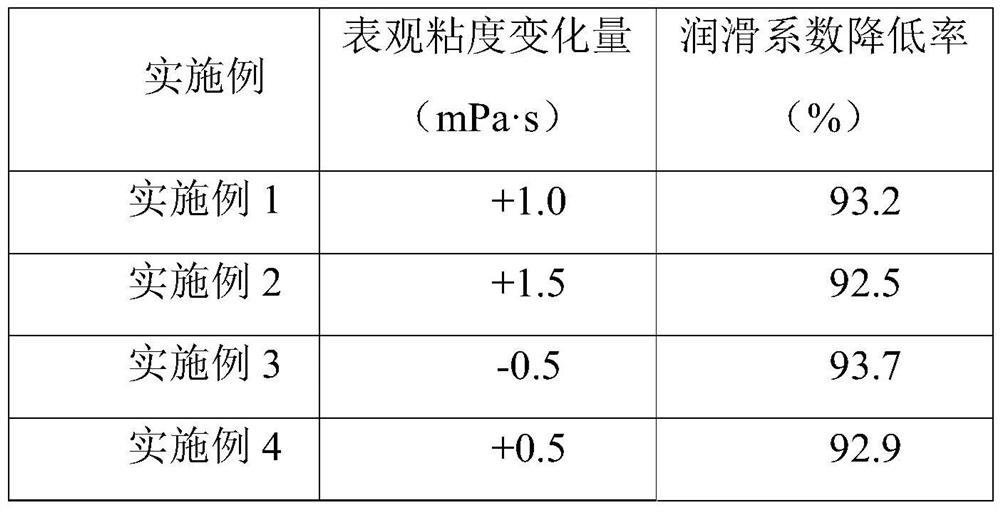

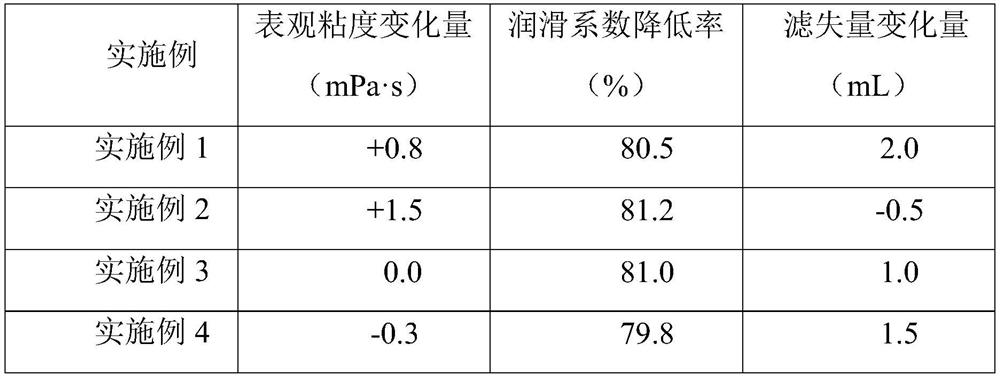

Solid Lubricant Polysaccharide Derivatives for Drilling Fluid

ActiveCN110105929BImprove the lubrication effectProduction conditions are easy to achieveDrilling compositionPtru catalystActive agent

The invention relates to a solid lubricant glycan derivative for a drilling fluid. Raw materials of the derivative comprise, 30-40 parts of hydroxypropyl guanidine gum, 3-4 parts of propylene epoxide,0.1-0.15 part of sodium hydroxide, 20-30 parts of dodecyl alcohol, 0.15-0.2 part of a catalyst, 10-20 parts of white oil, 2-5 parts of a surfactant, 0.1-2 parts of an antifoaming agent, 10-20 parts of mica powder, 1-3 parts of a bactericide, 6-10 parts of ethanol and 10-25 parts of water. A preparation method includes the steps that the hydroxypropyl guanidine gum, the sodium hydroxide and the water are added into a reaction still and stirred continuously, and the propylene epoxide is added for stirring, refluxing and a reaction; a reaction solution is heated, the catalyst is added, and a mixed solution of the ethanol and the dodecyl alcohol is added under stirring for a reaction; the reaction material solution is cooled to the room temperature, the white oil, the surfactant, the antifoaming agent, the mica powder and the bactericide are added, stirred uniformly, dried and ground into powder, and then the derivative is obtained. The lubricating coefficient reduction rate is higher than or equal to 90%, the derivative has good high-temperature drop reduction performance and salt resistance, the preparation conditions are easily achieved, and the derivative is environmentally friendly.

Owner:石家庄华莱鼎盛科技有限公司

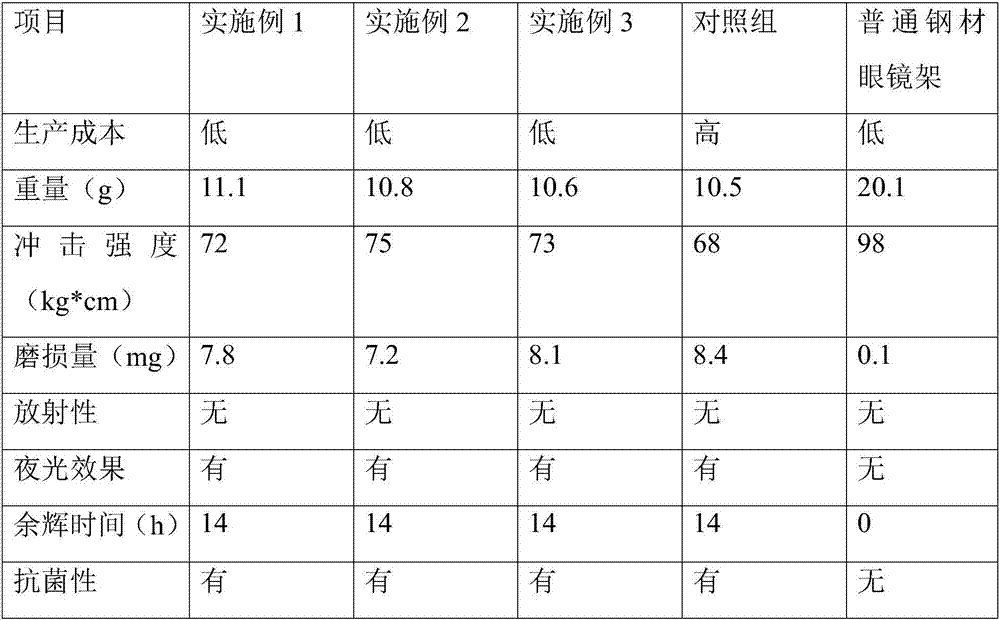

Composite carbon fiber spectacle frame and preparation process thereof

The invention relates to the field of spectacles, and especially relates to a composite carbon fiber spectacle frame and a production process thereof. The composite carbon fiber spectacle frame is prepared from the following raw materials, in parts by weight: 10-30 parts of carbon fibers, 20-40 parts of cellulose acetate fibers, 30-60 parts of epoxy resin, 1-3 parts of a wear resistant agent, 0.5-1.5 parts of an antibacterial agent, 0.5-1 part of a luminous material, 0.5-1 part of an antioxidant, 1-3 parts of a coupling agent, 0.5-1.5 parts of a lubricant, and 0.5-1.5 parts of a compatilizer. The composite carbon fiber spectacle frame has low production costs, high strength, long service life, antibacterial properties and a luminous effect, and is not easy to scratch and beneficial for human health and security.

Owner:东莞市鼎耀实业有限公司

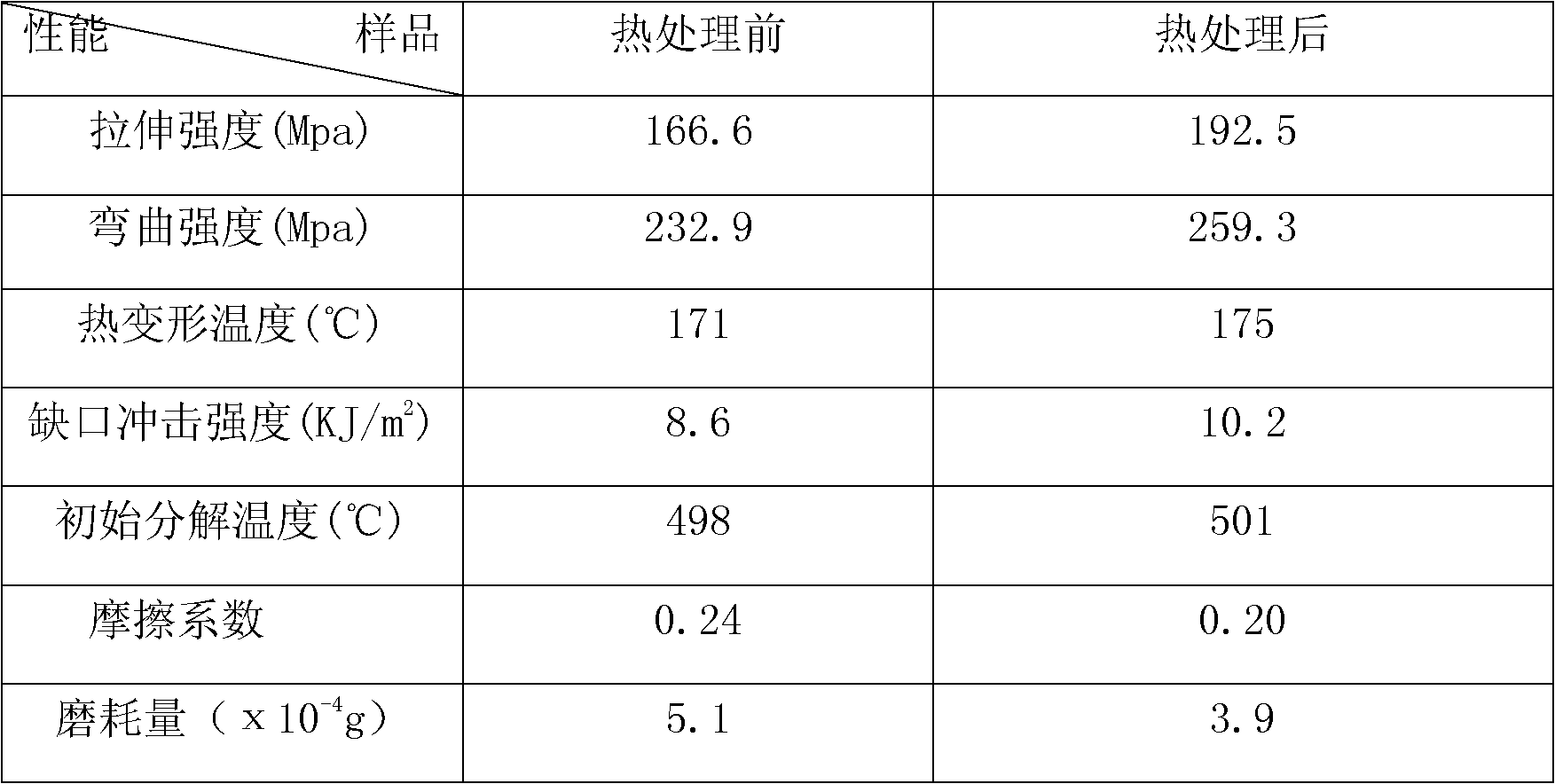

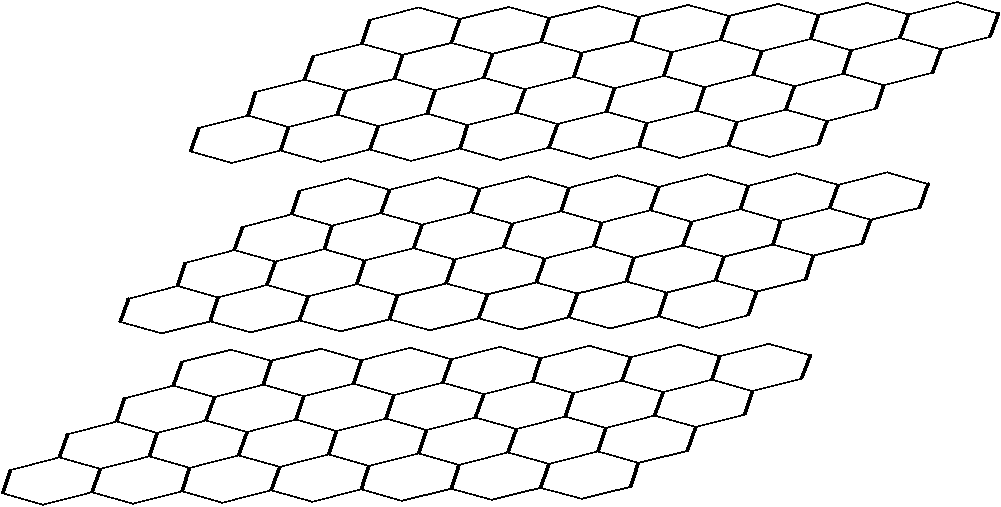

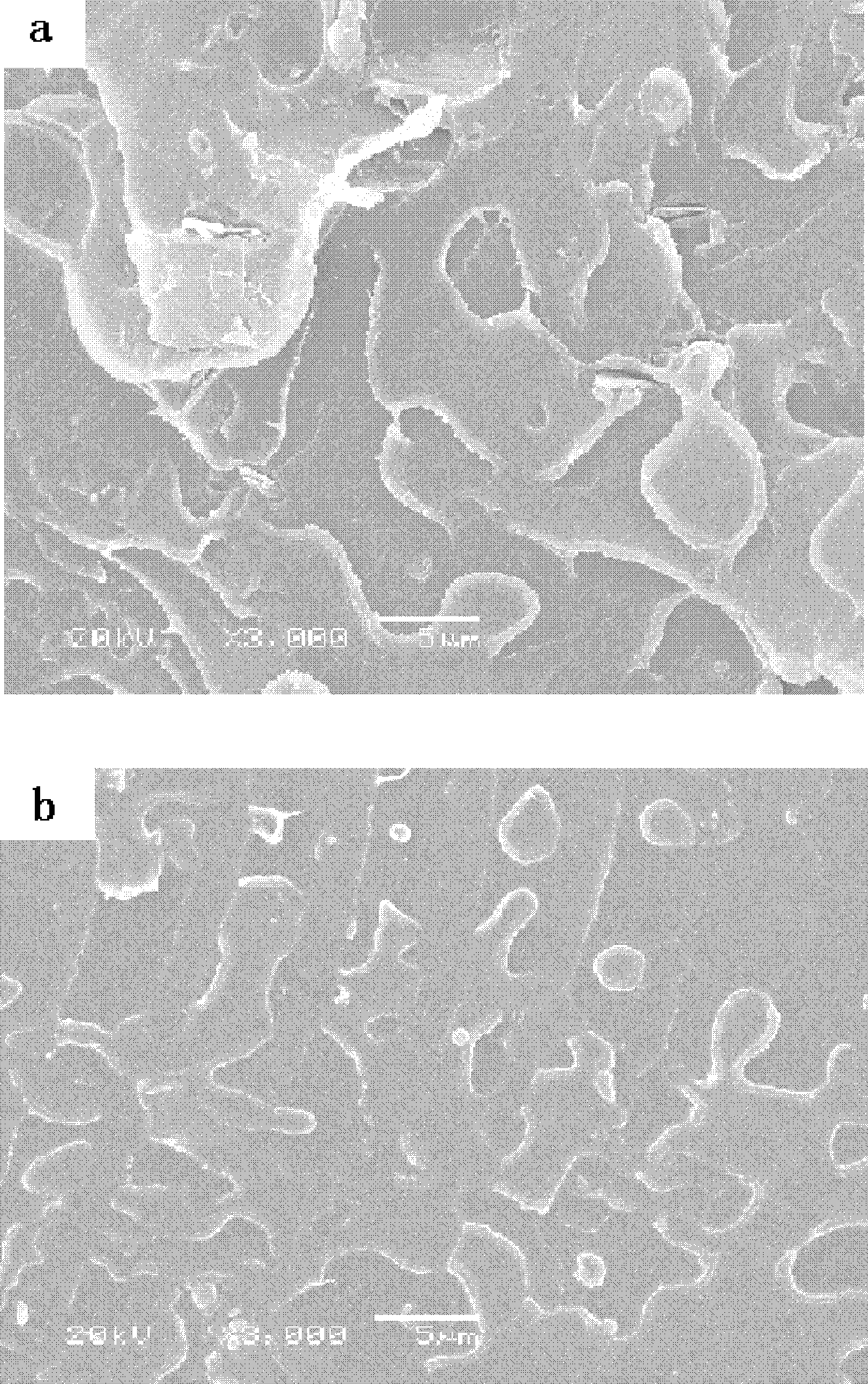

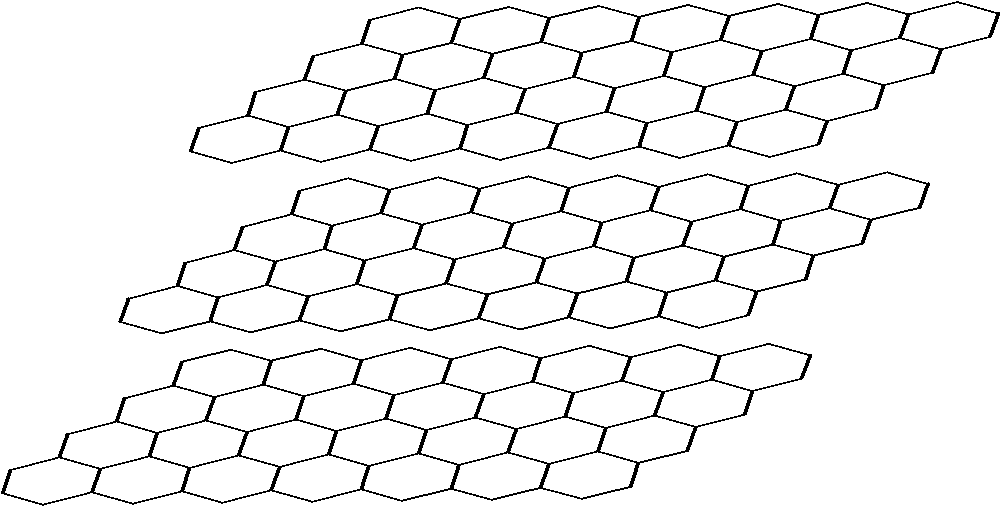

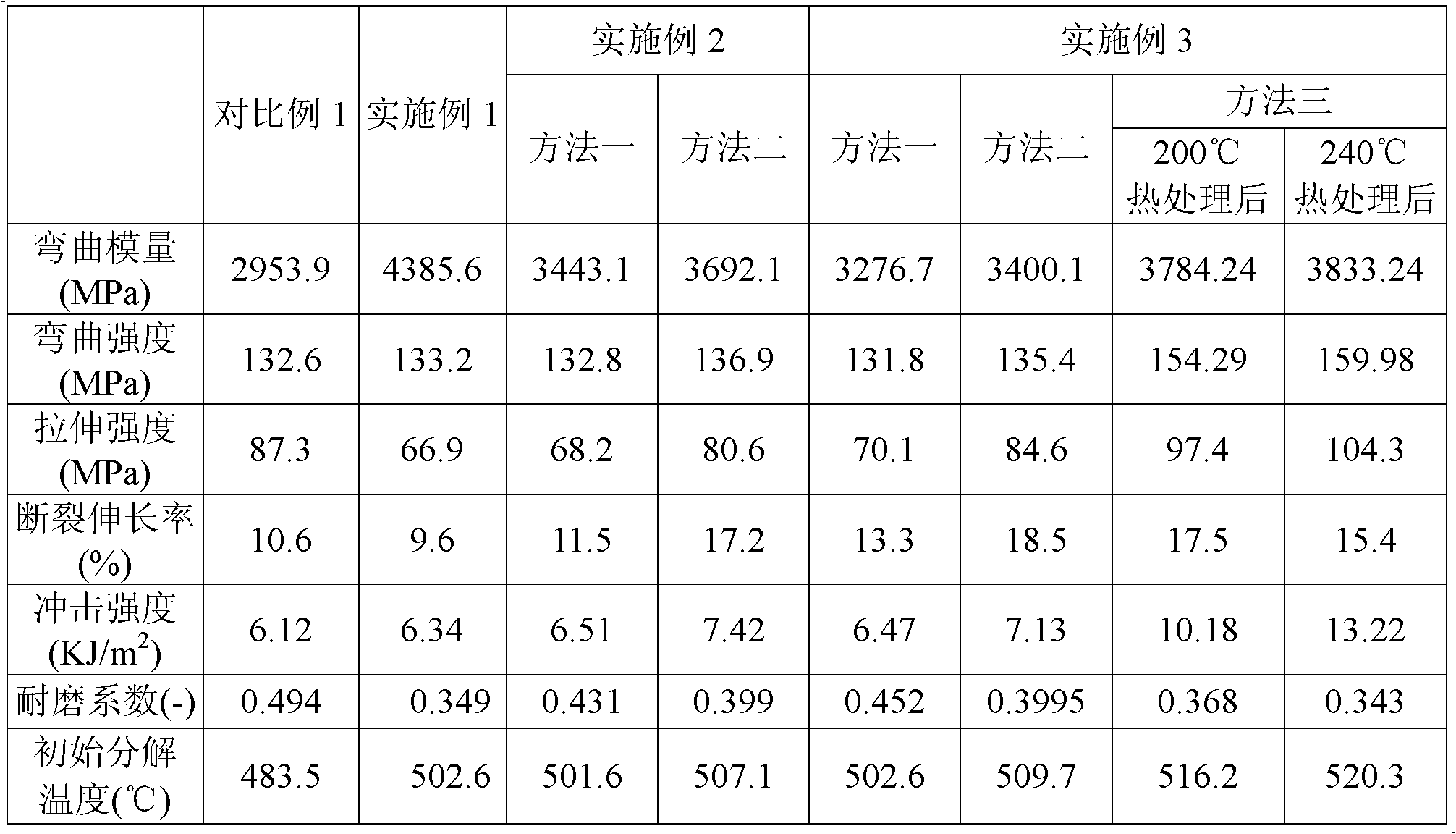

Poly(aryl ether nitrile) composite material and its preparation method

The invention belongs to the field of polymeric nanocomposites and specifically relates to a poly(aryl ether nitrile) composite material and its preparation method. A first technical problem to be solved in the invention is to provide the poly(aryl ether nitrile) composite material with good mechanical strength and wear resistance. The poly(aryl ether nitrile) composite material is prepared by adding graphene microchips into poly(aryl ether nitrile) resin, wherein, the addition amount of the graphene microchips is no more than 10% of the weight of the poly(aryl ether nitrile) composite material. The poly(aryl ether nitrile) composite material prepared in the invention has excellent comprehensive performance: a tensile strength the material is 80 to 120 MPa, elongation at break is 8 to 25%, a flexural strength is 120 to 170 MPa, a flexural modulus is 3200 to 4400 MPa, an impact strength is 6 to14 J / m<2>, the coefficient of friction is 0.3 to 0.5, and resistance to a high temperature as high as 500 DEG C is obtained; the composite material not only has substantially improved mechanical properties and wear resistance but also reduces application cost of poly(aryl ether nitrile) products.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

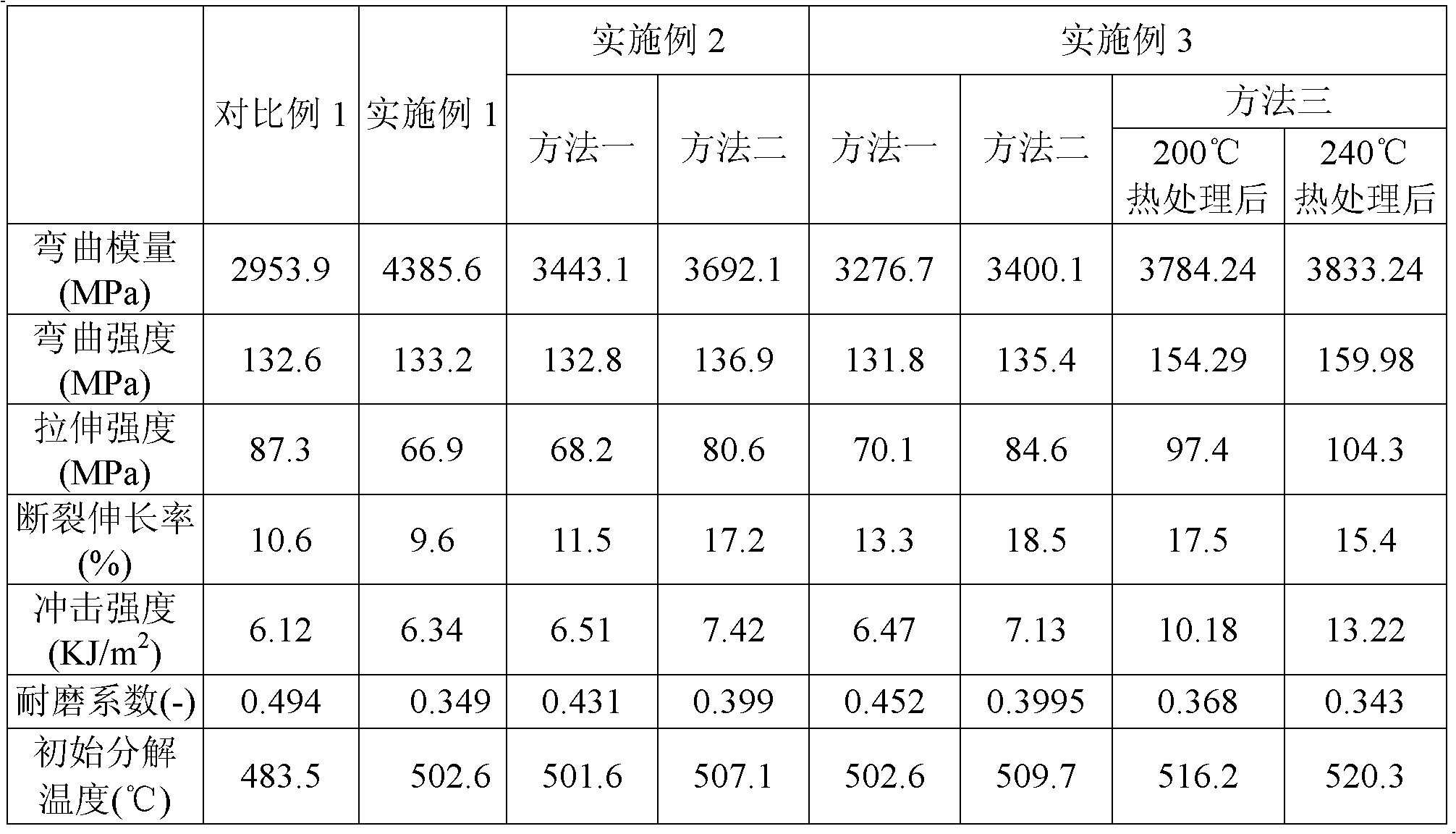

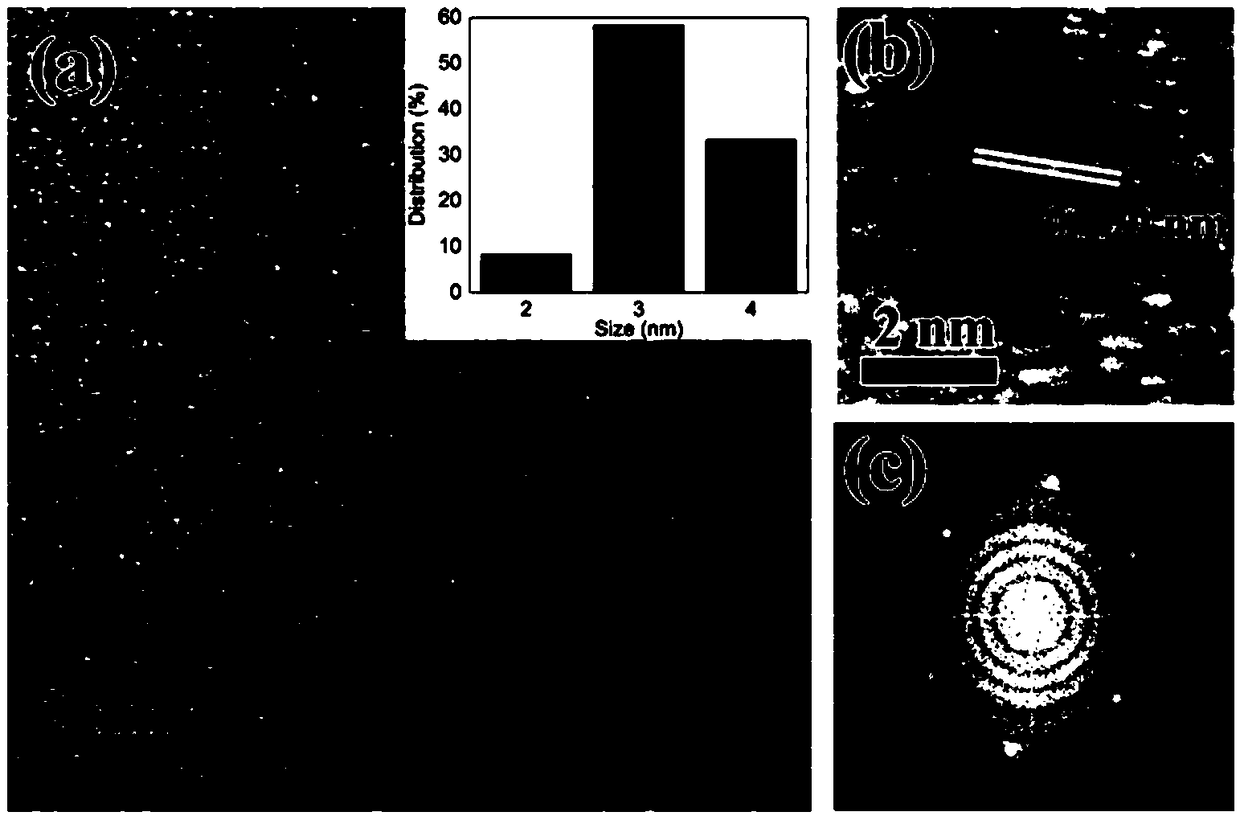

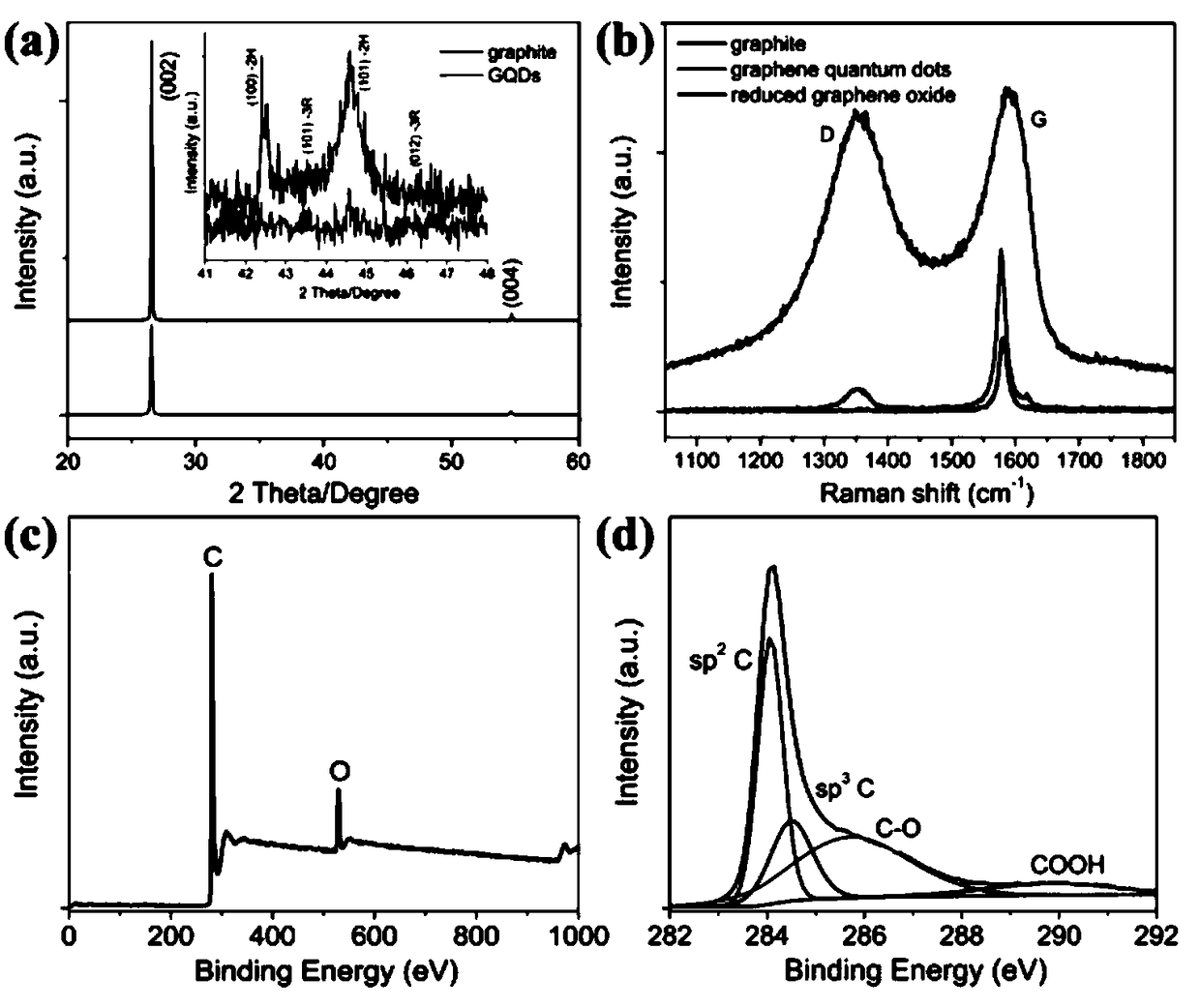

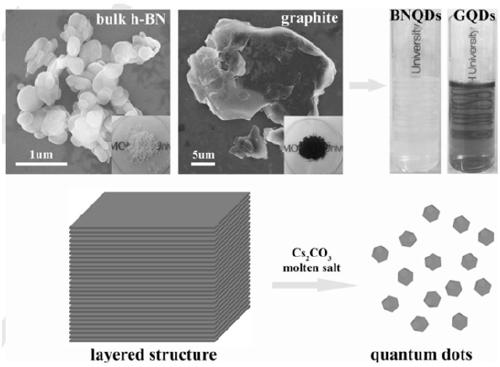

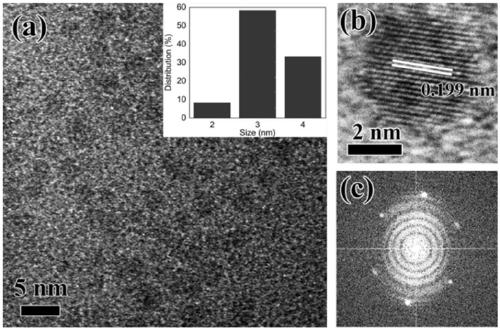

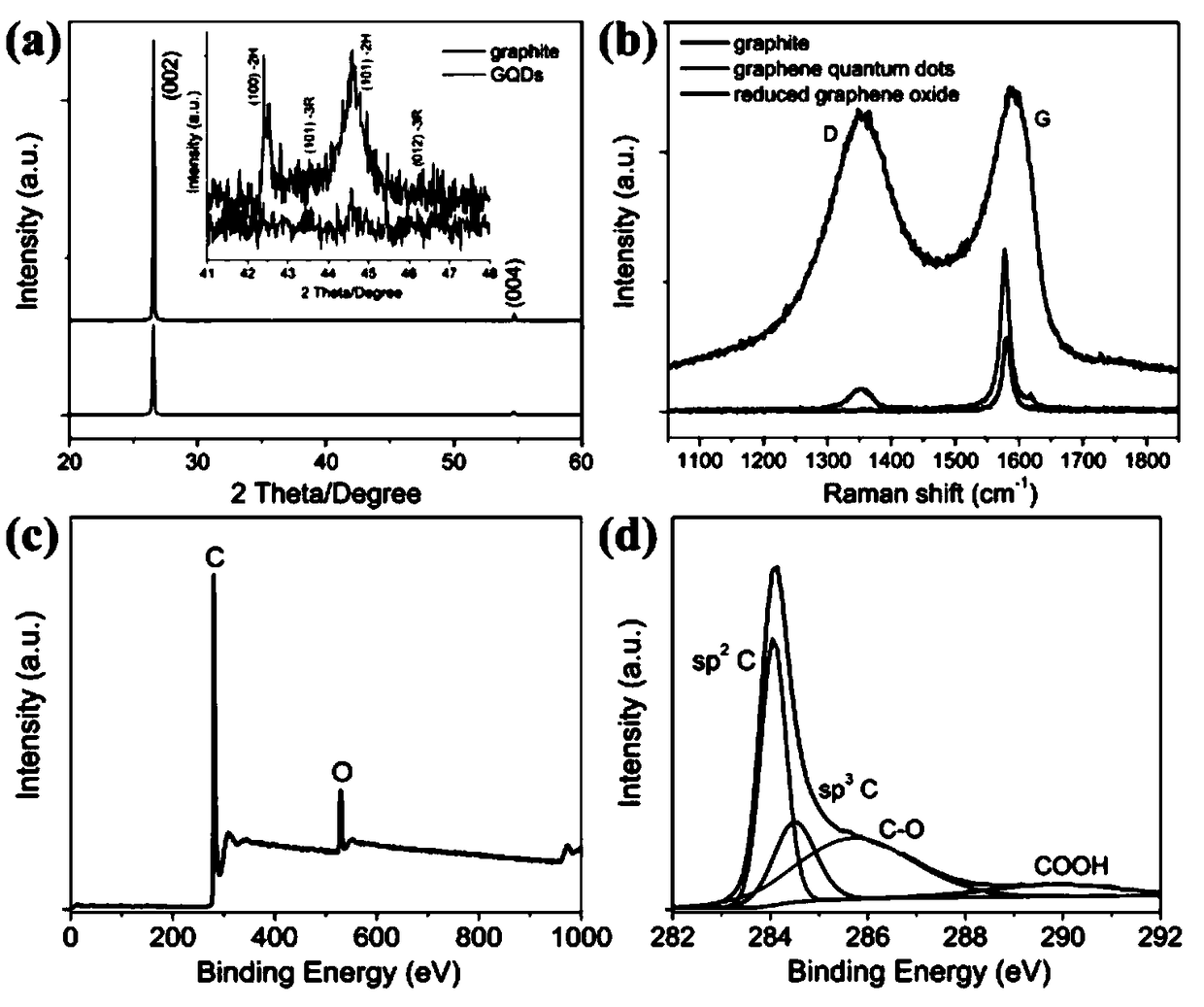

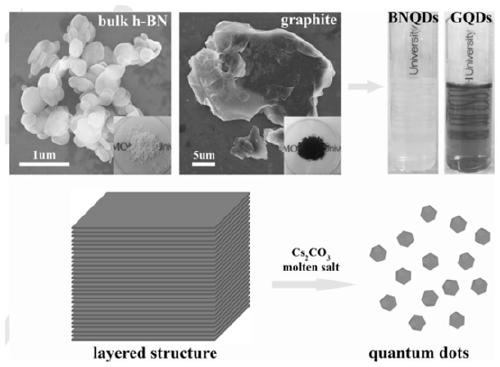

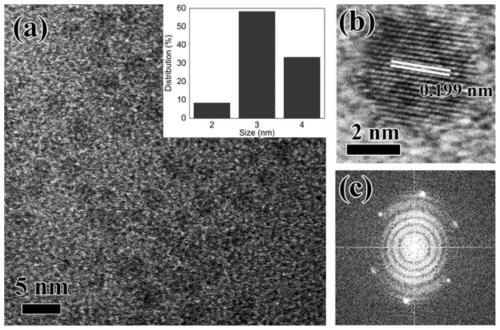

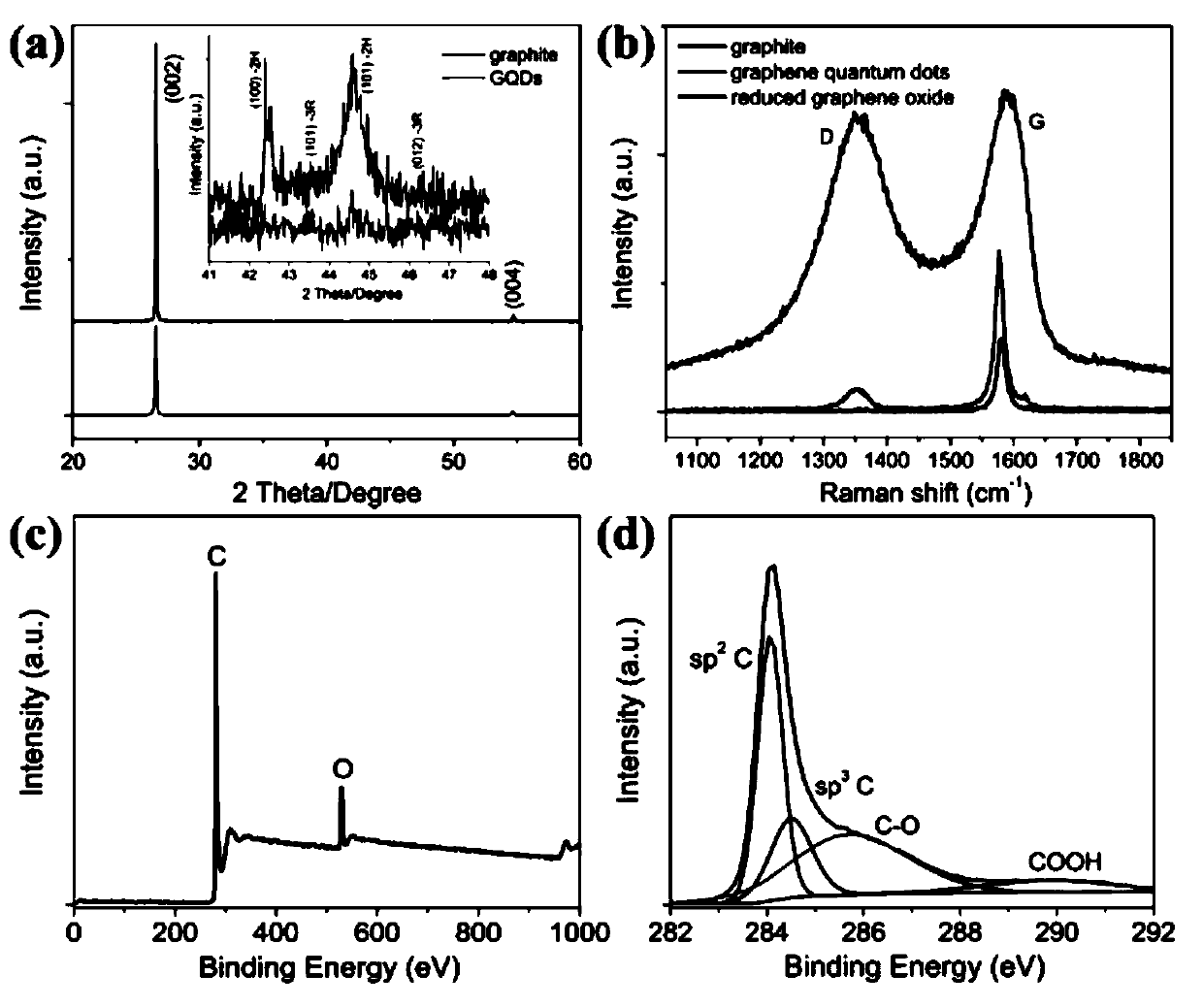

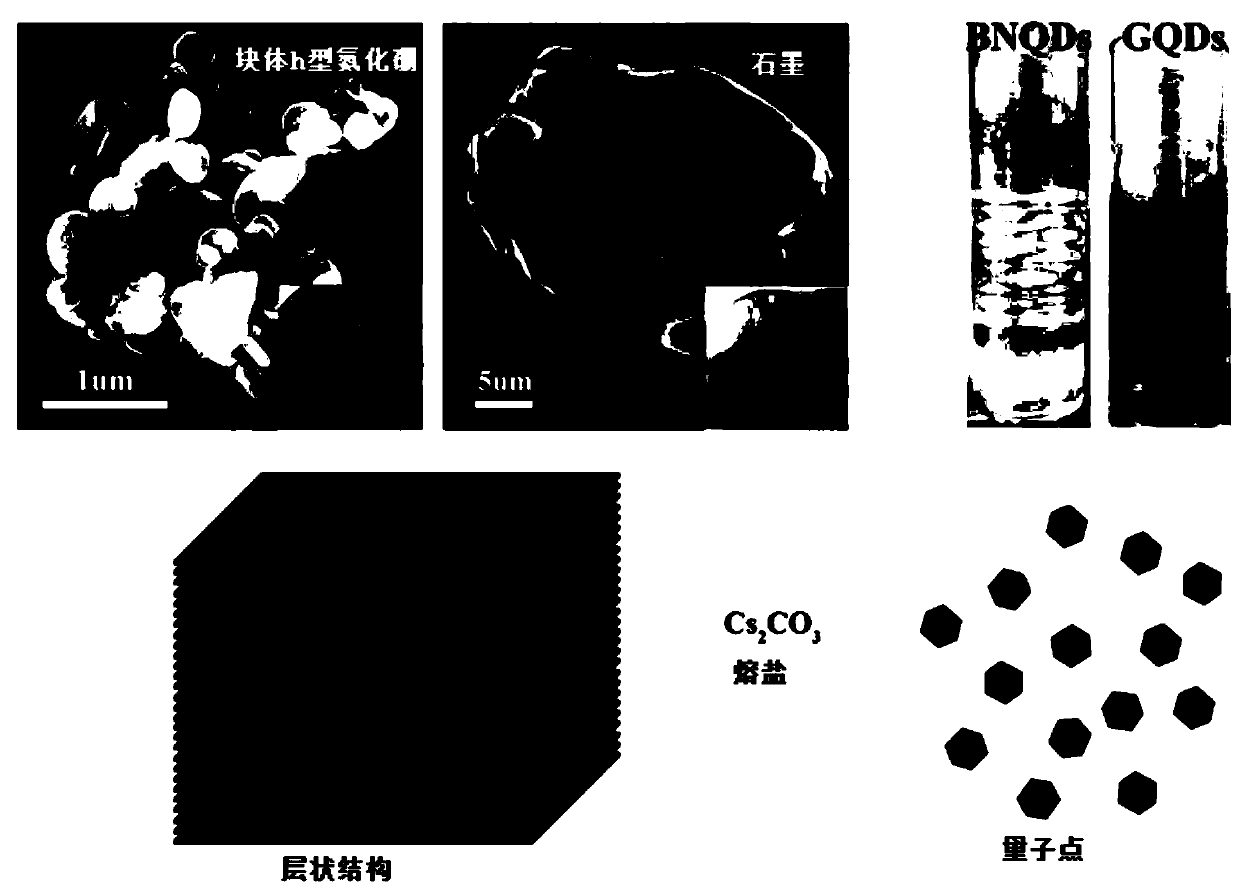

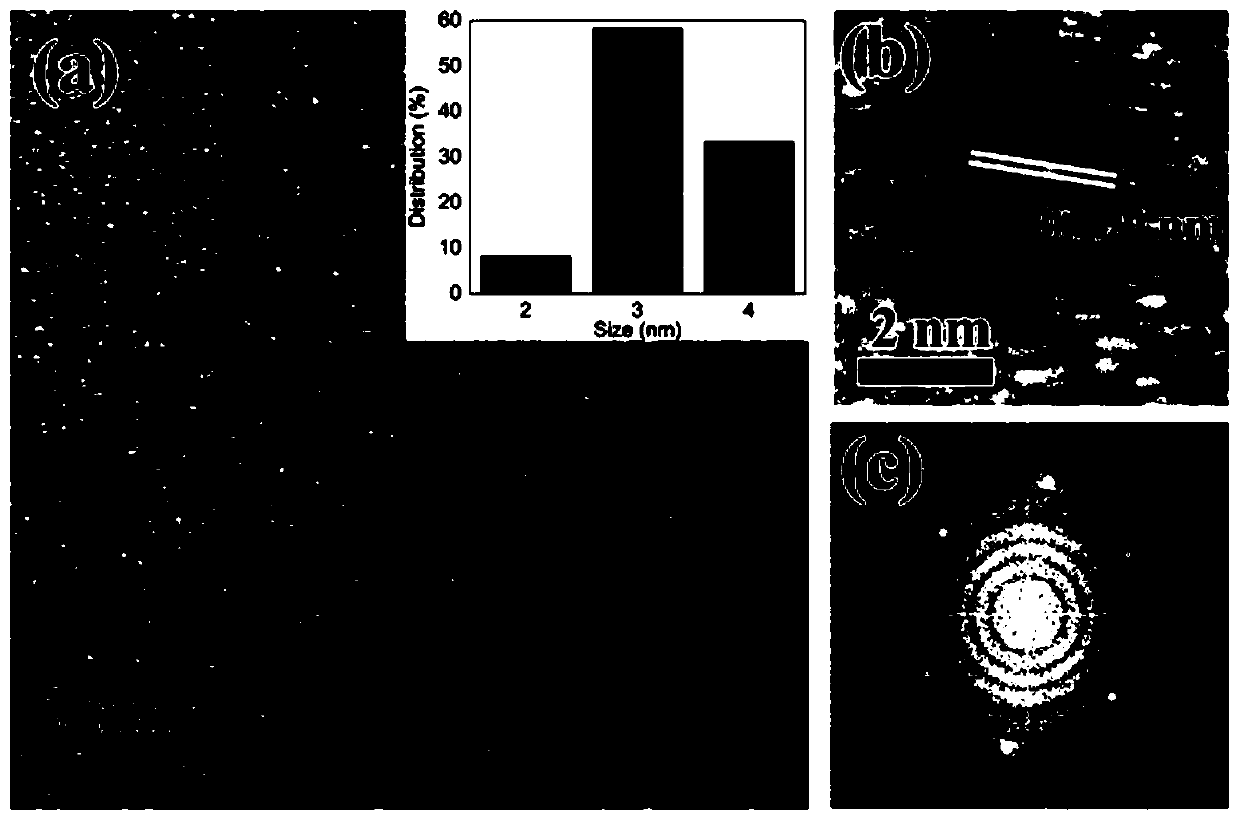

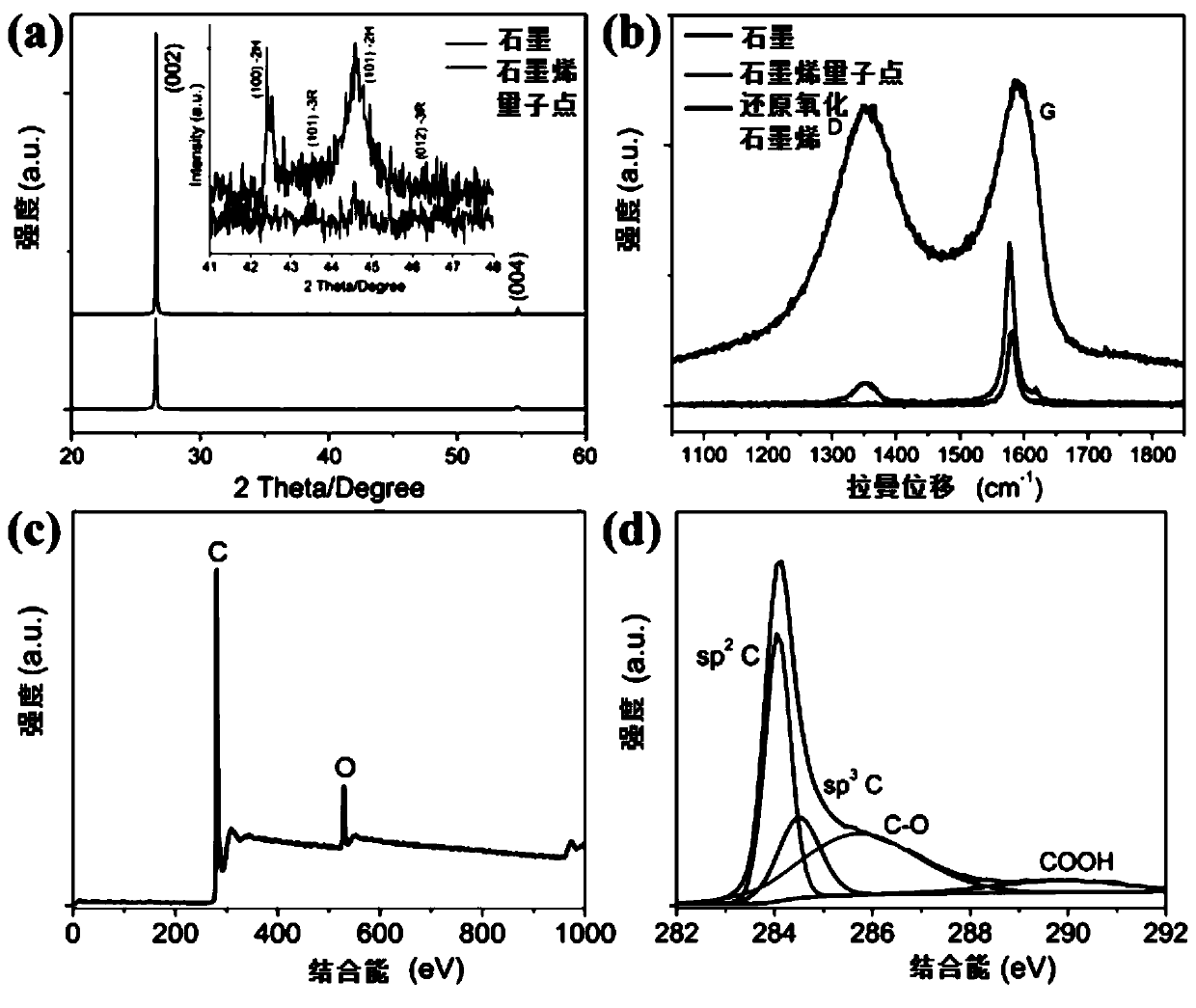

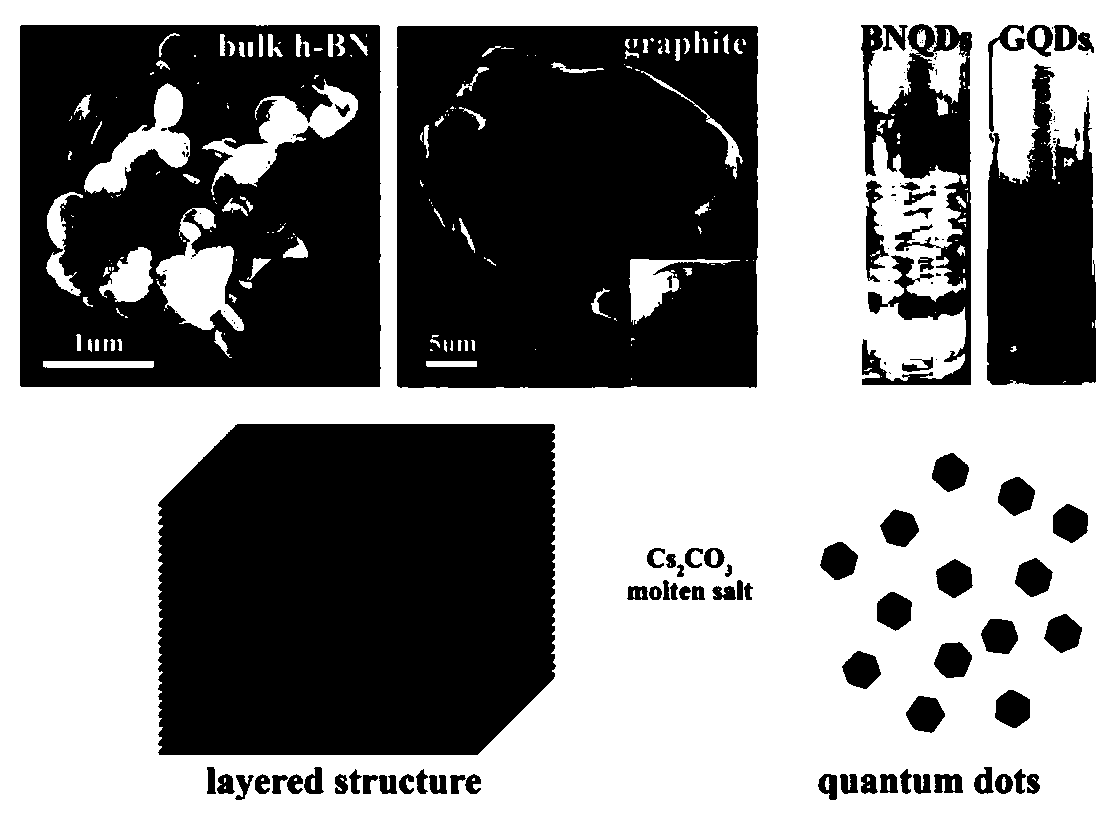

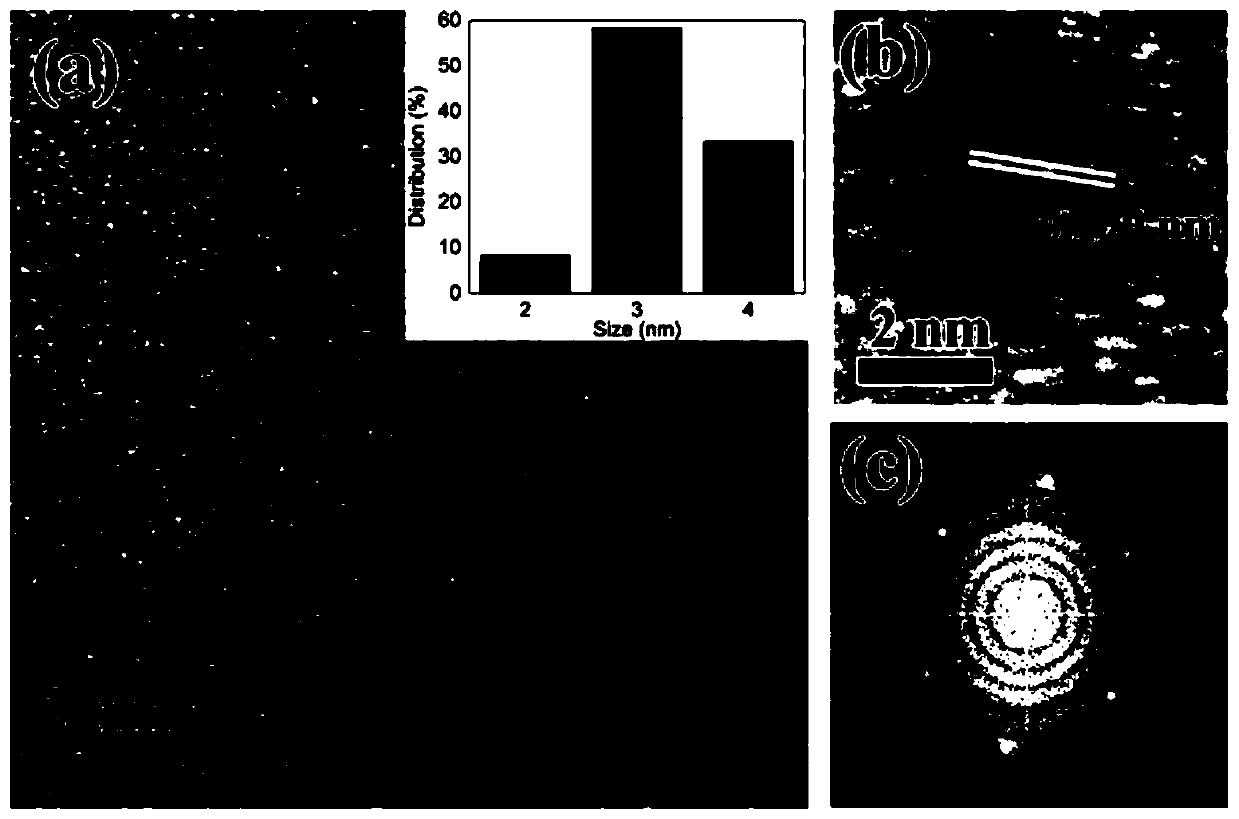

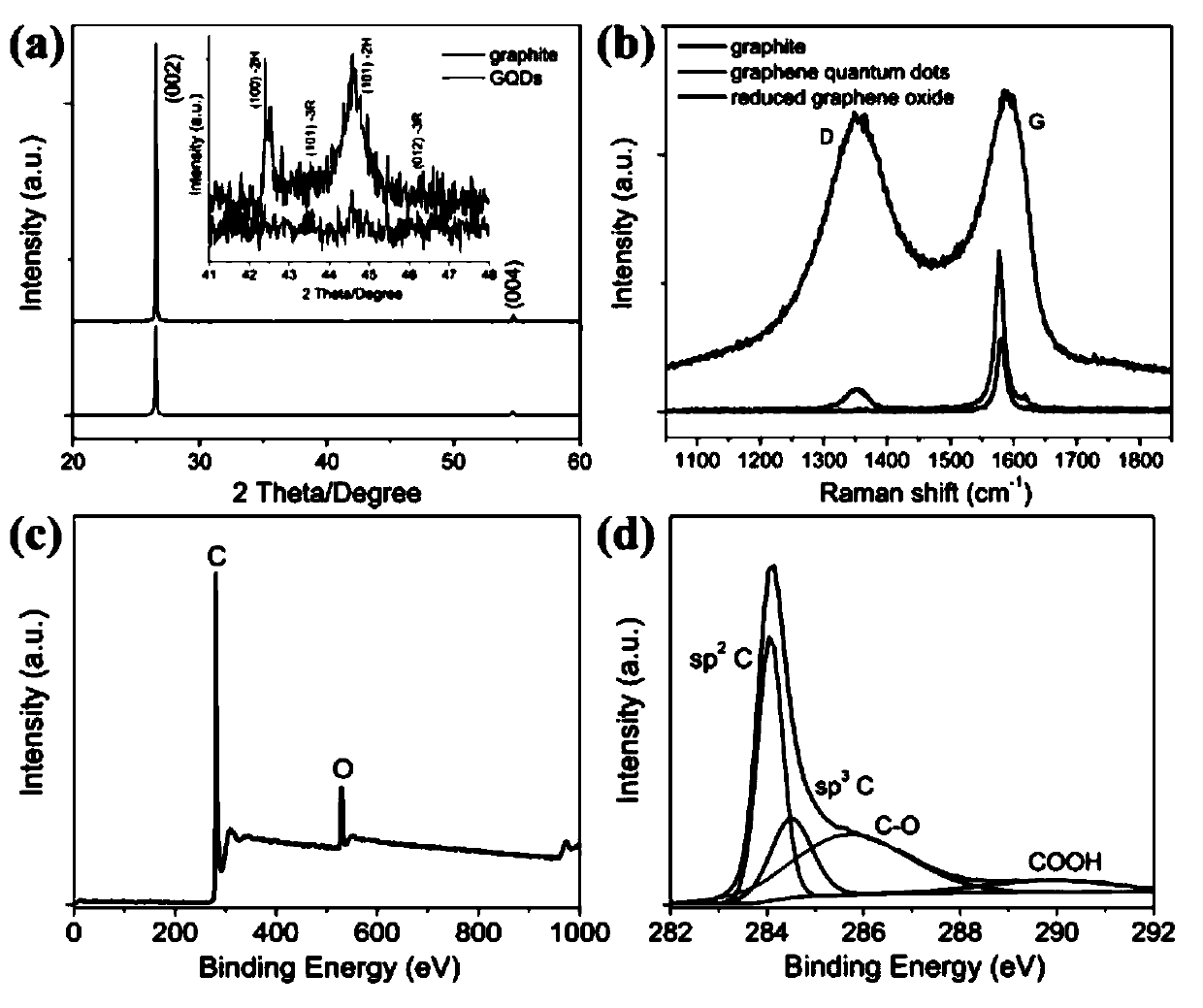

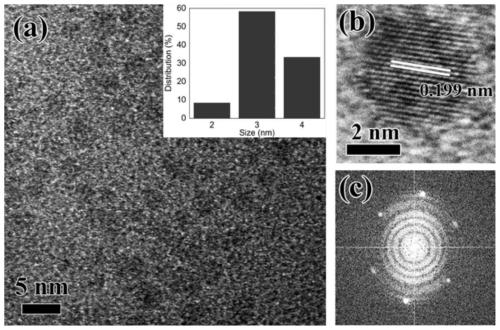

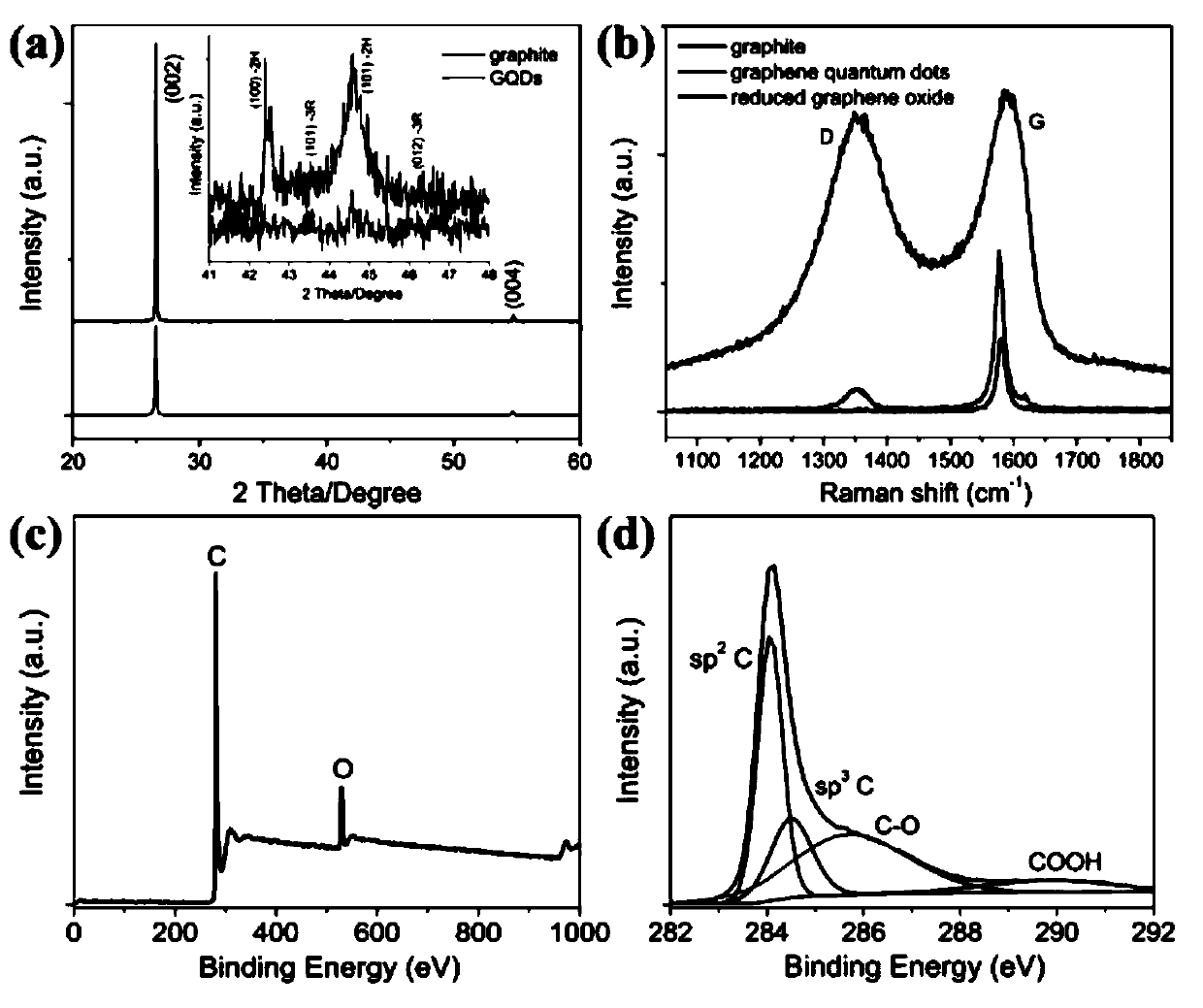

Graphene quantum dot-based pesticide detection method

ActiveCN109323896AImprove detection accuracyLow costMaterial analysis using wave/particle radiationPreparing sample for investigationRoom temperatureGraphite

The invention relates to the field of graphene quantum dots, in particular to a graphene quantum dot-based pesticide detection method. The method comprises the following steps of: a, preparing graphene quantum dots; and b, detecting the concentration of a pesticide by the quantum dots prepared in the step a. The preparation of the graphene quantum dots comprises the steps of: (1) mechanically mixing graphene blocks with a fused salt catalyst; (2) preheating the mixture in the step (1) and preserving the heat; (3) directly heating the heat preserved mixture in the step (2) and preserving the heat; (4) cooling the mixture in the step (3) to room temperature, and soaking the mixture in water to obtain suspension; and (5) carrying out centrifugal filtration on the suspension in the step (4) toobtain graphene quantum dots. The preparation method of the graphene quantum dots is low in cost, high in graphitization degree and good in finished product quality, so that the pesticide detection method is capable of accurately detecting the concentrations of pesticides and is suitable for large-scale production.

Owner:DONGGUAN UNIV OF TECH

Preparation method for phytosterol acetate formed by catalytic synthesis through enzymic method

ActiveCN102703557BSimple production equipmentProduction conditions are easy to achieveFermentationOrganic solventPhytosterol

The invention relates to a preparation method for phytosterol acetate formed by catalytic synthesis through an enzymic method. The preparation method comprises the following steps: dissolving pyruvic acid and phytosterin as reaction substrates into dehydrated organic solvent; adding immobilized lipase and a dehydrating agent; and carrying out an oscillating reaction in a water bath of 40-60DEG C for 16-20 hours to obtain the phytosterol acetate, wherein the esterification rate is high as high as 93.01 percent. According to the preparation method disclosed by the invention, the phytosterol acetate is prepared from the pyruvic acid and the phytosterin as raw materials. The preparation method has the advantages of requirement on simple equipment, environment friendliness, safety and higher esterification rate.

Owner:SOUTH CHINA UNIV OF TECH

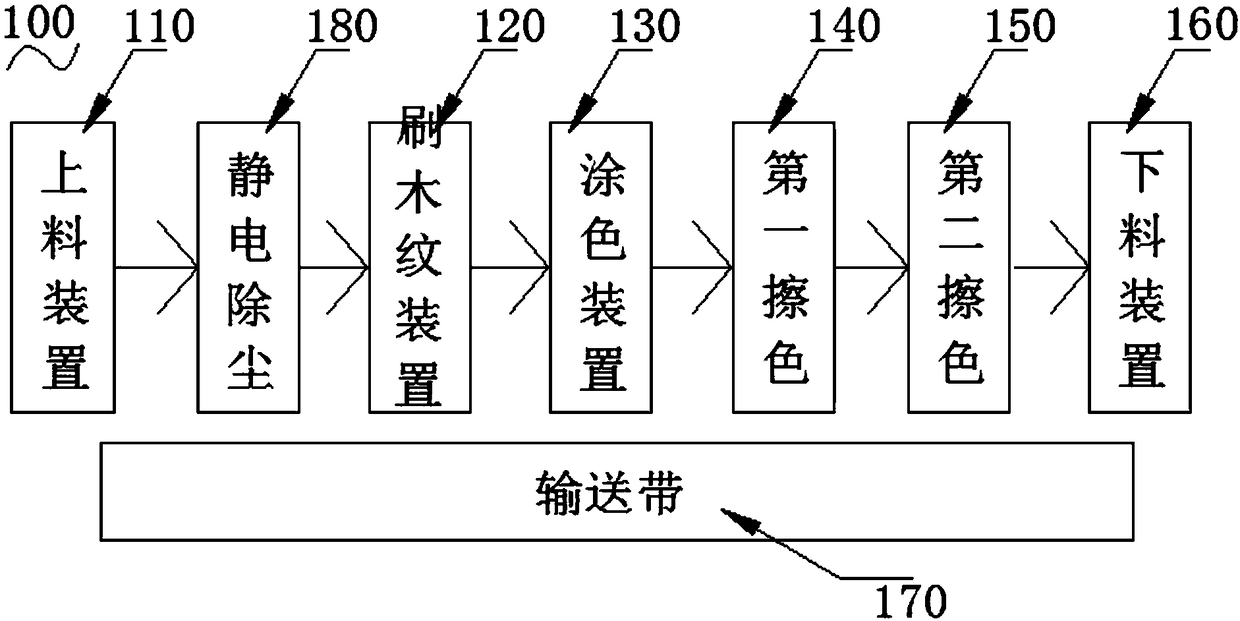

Oak board color wiping system and color wiping process

InactiveCN108407529AUniform coatingHigh degree of automationMechanical surface treatmentSpecial ornamental structuresBrush devicePulp and paper industry

The invention relates to the field of furniture, in particular to an oak board color wiping system and a color wiping process. The oak board color wiping system comprises a loading device, a wood grain brushing device, a coloring device, a first color wiping device, a second color wiping device and an unloading device, and further comprises a conveying belt for conveying oak boards; and the conveying belt penetrates through the loading device, the wood grain brushing device, the first color wiping device, the second color wiping device and the unloading device in sequence. The oak board colorwiping system is high in working efficiency, uniform in color wiping and beautiful in furniture appearance.

Owner:挪亚家家具(广东)有限公司

Method for preparing poly(arylene ether nitrile) resin

The invention discloses a method for preparing poly(arylene ether nitrile) resin, which belongs to the technical field of high polymer materials. The method comprises the following steps of: finishing a reaction in a reaction kettle under normal pressure under the actions of a catalyst and a dehydrating agent by taking 2,6-dichlorobenzonitrile and aromatic dicarboxylic phenol as raw materials andtaking N-methyl pyrrolidone as a solvent; pressurizing and atomizing solution after dilution to a precipitating agent for precipitating; after heating, stirring and refluxing a precipitate and the precipitating agent to finish solvent extraction, performing solid-liquid separation by using a centrifugal machine; allowing liquid to enter a rectifying tower for rectifying and recovering the solvent; and drying solid after washing with boiling water to obtain the poly(arylene ether nitrile) resin of the invention. The method has the characteristics of easily implemented production conditions, and safe and environmentally-friendly production process. The poly(arylene ether nitrile) resin prepared by adopting the method of the invention has the characteristics of high purity and stable performance, and can be applied to the field of aerospace, electronics, machinery, medical treatment, chemical industry and the like.

Owner:SICHUAN FEIYA NEW MATERIAL

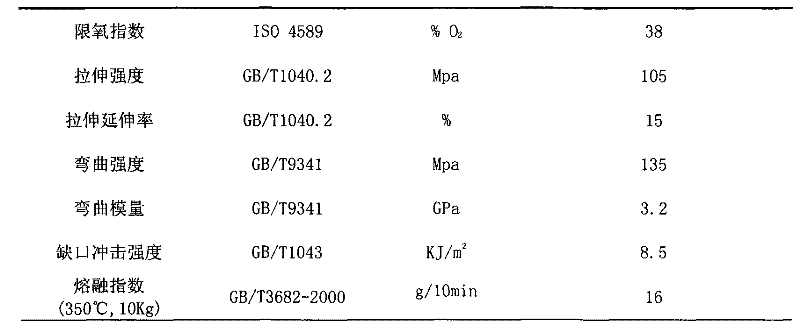

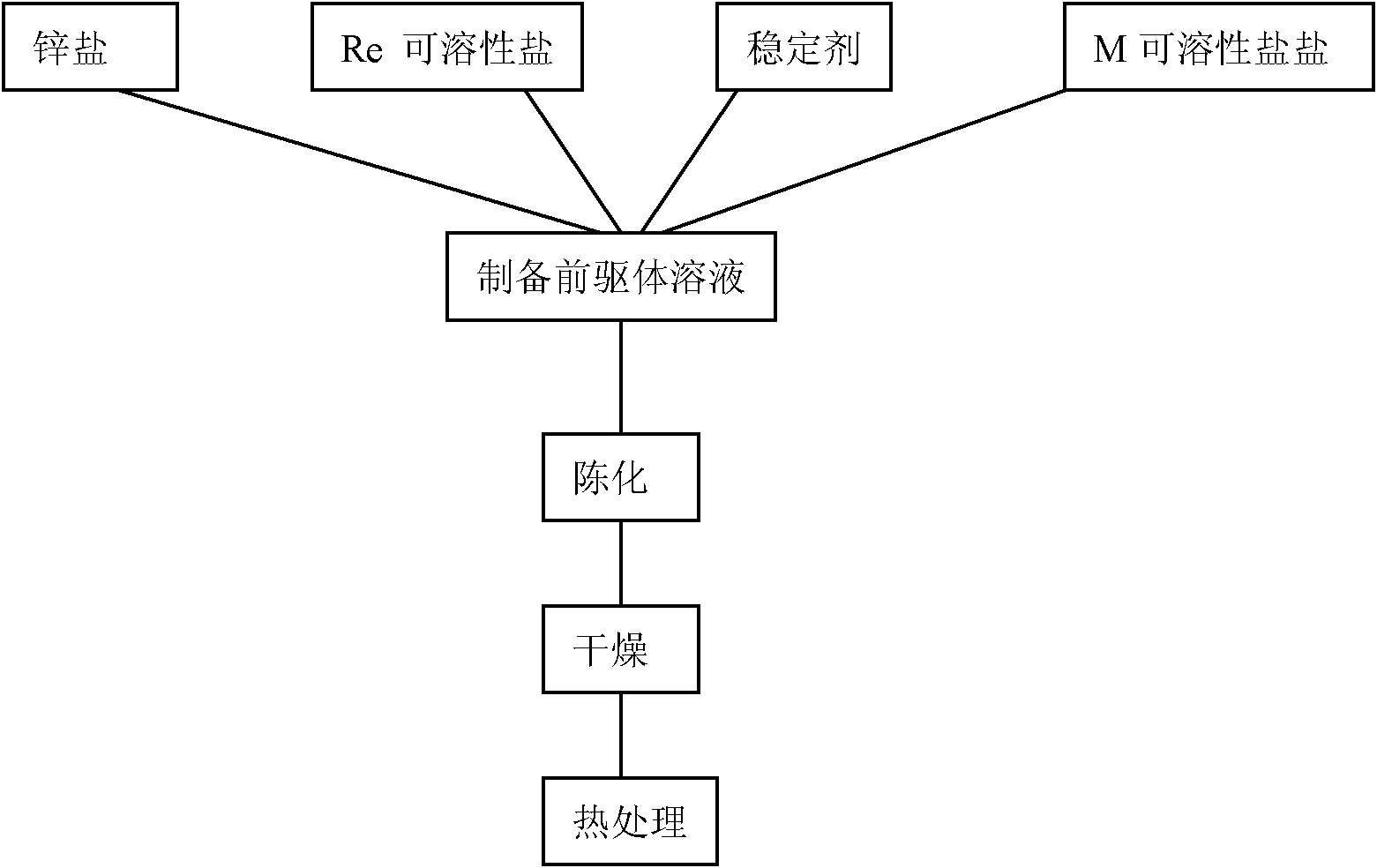

Zinc oxide based fluorescent powder and preparation method thereof

InactiveCN102268255BHigh luminous intensityEvenly distributedLuminescent compositionsLuminous intensityColloid

The invention discloses zinc oxide based fluorescent powder and a preparation method thereof. The chemical formula of the fluorescent powder is Zn1-xRexO:yM, wherein Re is one or two of Eu, Tb, Er and Dy; M is one of Ag, Au, Pt and Pd; y is the molar ratio of M to Zn1-xRexO; x is greater than or equal to 0.001 and less than or equal to 0.10; and y is greater than or equal to 0.00002 and less thanor equal to 0.01. The preparation method comprises the following steps of: preparing fluorescent powder colloid through a sol-gel method; and performing thermal treatment at a high temperature to obtain the zinc oxide-based fluorescent powder. The zinc oxide based fluorescent powder provided by the invention has high luminous intensity; and the preparation method has a simple process and a short preparation period and can be used for preparing a light-emitting material.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

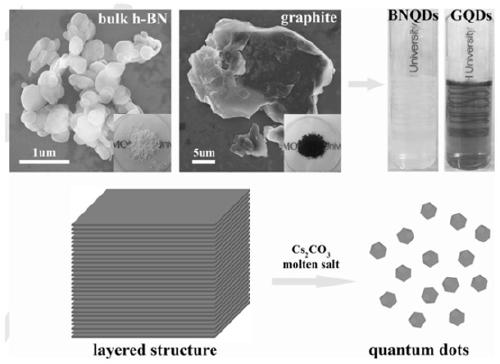

Graphene quantum dot and preparation method thereof

ActiveCN109319766AHigh degree of graphitizationHigh purityMaterial nanotechnologyGrapheneRoom temperatureMolten salt

The invention relates to the field of graphene quantum dots, and particularly relates to a graphene quantum dot and a preparation method thereof. The preparation method of the graphene quantum dot comprises the following steps: (1), taking a graphite powder block to mechanically mix with a molten salt catalyst; (2), taking a mixed material in the step (1) to carry out preheating treatment and heatpreservation; (3), taking the mixed material subjected to the heat preservation in the step (2) to directly heat up and carry out the heat preservation; (4), cooling the mixed material in the step (3) to the room temperature, and then carrying out water immersion treatment to obtain suspension liquid; and (5), taking suspension liquid in the step (4), and carrying out centrifugal filtration to obtain a graphene quantum dot product. The preparation method of the graphene quantum dot, which is provided by the invention, has the advantages of low manufacturing cost, high graphitization degree, and good finished-product quality, and is applicable to large-scale production.

Owner:DONGGUAN UNIV OF TECH

Rapid and green preparation method of epoxidation soybean oil

ActiveCN103224837BShort reaction timeImprove conversion efficiencyFatty acid chemical modificationSOYBEAN SEED OILActive agent

The invention relates to a fast and green method for preparing epoxidized soybean oil. After mixing soybean oil with a non-aqueous organic solvent, adding a heteropolyacid phase transfer catalyst and a surfactant polyethylene glycol, heating in a water bath, and reacting Hydrogen peroxide was added dropwise during the process. Separate the organic phase and distill under reduced pressure to obtain epoxidized soybean oil. The reaction time is 3.0-4.0h, the epoxidation value is greater than 6.30%, and the conversion rate is higher than 90%. In the present invention, by adding the surfactant polyethylene glycol, the production time is shortened, the process is simple, safe and non-toxic, the equipment is not damaged, the environment is friendly, and the product has high epoxidation value and conversion rate.

Owner:SOUTH CHINA UNIV OF TECH

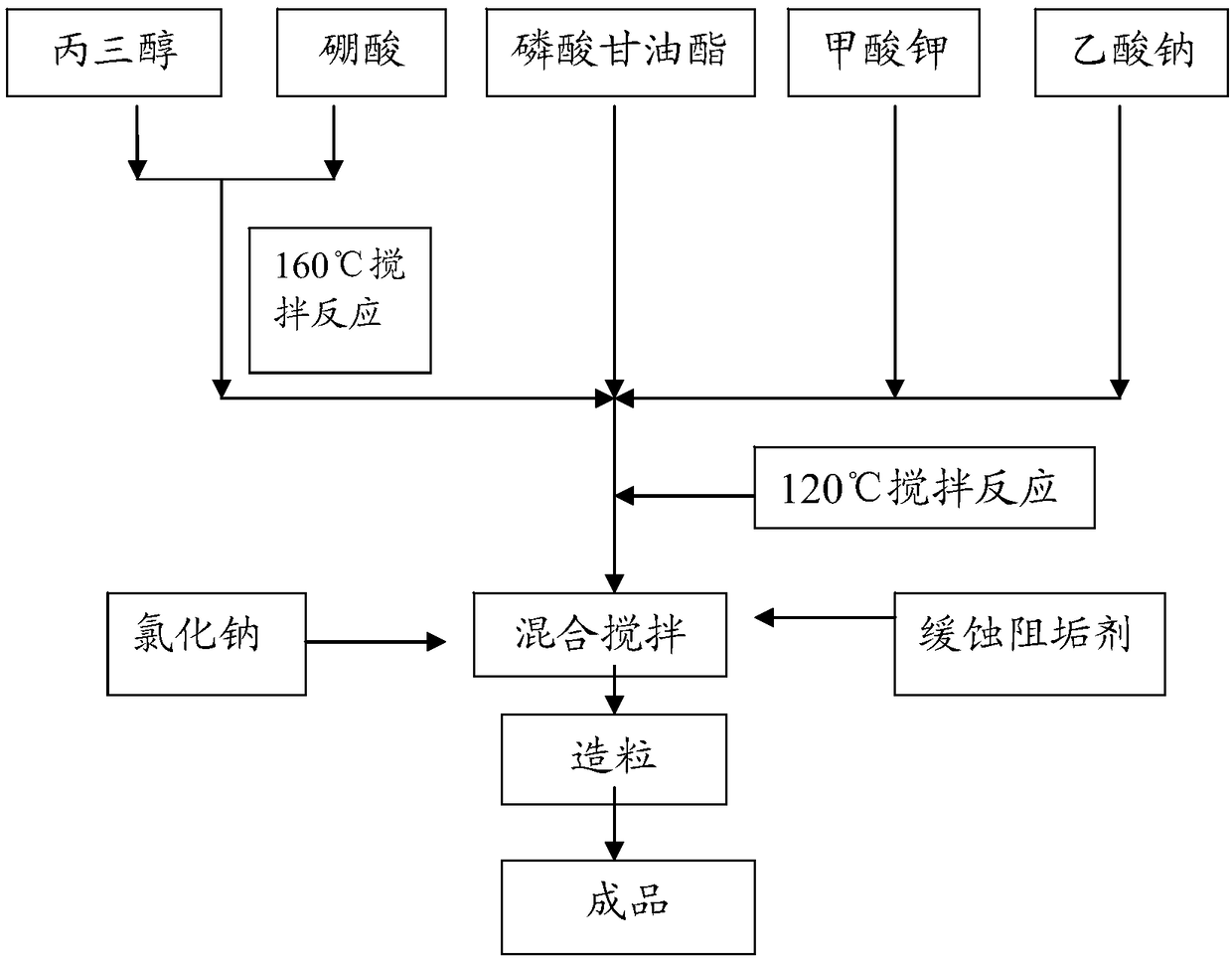

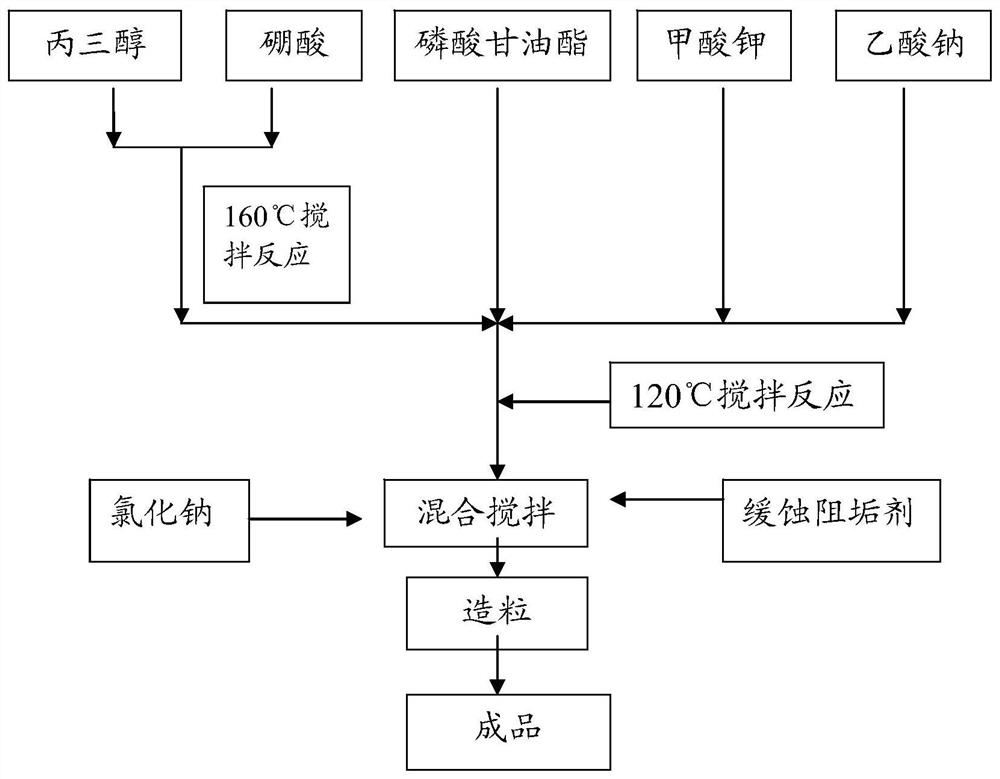

Low-chlorine environment-friendly snow melt agent without salt dust and method for preparing low-chlorine environment-friendly snow melt agent

The invention discloses a low-chlorine environment-friendly snow melt agent without salt dust and a method for preparing the low-chlorine environment-friendly snow melt agent. The low-chlorine environment-friendly snow melt agent and the method have the advantages that the low-chlorine environment-friendly snow melt agent is in the shape of yellowish-brown particles, the particle size of the low-chlorine environment-friendly snow melt agent is 0.3-0.6 cm, the chlorine content of the low-chlorine environment-friendly snow melt agent is lower than the chlorine content of common snow melt agentsby 15% or above, environmental hazards of the low-chlorine environment-friendly snow melt agent can be reduced by 30%-40%, the low-chlorine environment-friendly snow melt agent contains little chloride, and accordingly destruction and pollution on soil, plants and underground water resources due to the low-chlorine environment-friendly snow melt agent are far lower than destruction and pollution due to the common snow melt agents; earth surfaces are free of white salt spots after snow removal operation is carried out, salt dust formation can be effectively inhibited, and secondary pollution can be prevented.

Owner:金宝特兴(北京)科技开发有限公司

Ammonia electrochemical synthesis catalyst based on graphene quantum dots and preparation method of ammonia electrochemical synthesis catalyst

The invention relates to the field of graphene quantum dots, in particular to a preparation method of an ammonia electrochemical synthesis catalyst based on graphene quantum dots. The preparation method includes the steps of firstly, mechanically mixing graphite powder lumps and a fused-salt catalyst, wherein the fused-salt catalyst is the mixture of cesium carbonate fused salt and fused salt containing iron and molybdenum; secondly, subjecting the mixture obtained in the first step to thermal treatment and heat preservation; thirdly, directly heating the mixture obtained after the heat preservation in the second step, and performing heat preservation; fourthly, cooling the mixture obtained after the third step to room temperature, and soaking with water to obtain a suspension; fifthly, subjecting the suspension obtained in the fourth step to centrifugal filtering to obtain the ammonia electrochemical synthesis catalyst. The ammonia electrochemical synthesis catalyst is low in preparation cost, high in graphitization degree, good in quality, high in ammonia synthesis catalytic efficiency and applicable to large-scale production.

Owner:DONGGUAN UNIV OF TECH

Bisphenol A type polyarylene sulfide ether nitrile resin and preparation method thereof

A bisphenol A type polyarylene sulfide ether nitrile resin and a preparation method thereof belong to the technical field of polymer materials. The invention uses 2,6-dichlorobenzonitrile, sodium sulfide and bisphenol A as raw materials, uses N-methylpyrrolidone as a solvent, and completes the reaction in a reactor under normal pressure under the action of catalyst potassium carbonate and dehydrating agent toluene. After the reaction solution is precipitated by the precipitant, the particles obtained by pulverizing the precipitate with a pulverizer are ground in a colloid mill to obtain an emulsified fine powder. Then soak the fine powder in an organic solvent and separate the solid from the liquid in a centrifuge. The liquid enters a rectification tower to rectify and recover the solvent. The solid is washed with boiling water and then dried to obtain the bisphenol A polyarylene sulfide ether nitrile resin of the present invention. The production conditions of the invention are easy to realize, and the production process is safe and environment-friendly. The bisphenol A type polyarylene sulfide ether nitrile resin prepared by the method of the invention has stable performance and can be applied to the fields of aerospace, electronics, machinery, medical treatment, chemical industry and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing 10-deacetylbaccatin III by utilizing paclitaxel-semisynthesis impurity

InactiveCN106632159AHigh yieldSolve cumulative problemsOrganic chemistryDocetaxel10-Deacetylbaccatin

The invention relates to a method for preparing 10-deacetylbaccatin III by utilizing a paclitaxel-semisynthesis impurity. A paclitaxel-semisynthesis impurity raw material is dissolved by using an organic solvent; hydrazine hydrate is added into an obtained first mixture to hydrolyze the first mixture; an acidifying agent is added into hydrolyzed mixed liquor to carry out acidification; acidified liquor is neutralized by using weak base, so that the 10-DAB III (10-deacetylbaccatin III) is obtained. According to the method provided by the invention, the paclitaxel-semisynthesis impurity is used as a raw material, is first hydrolyzed by using the hydrazine hydrate, and then is treated by using the acidifying agent to obtain a 10-DAB III coarse product; the 10-DAB III coarse product is purified by using a silica gel chromatographic column to obtain a 10-DAB III product; the 10-DAB III has a yield which is up to 25.6 to 36.8 percent and a content which is up to 98.2 to 99.1 percent; a new approach of obtaining the 10-DAB III product is exploited; not only is the accumulation problem of the impurity in a paclitaxel semisynthesis process solved, but also the raw material is provided for the semisynthesis of paclitaxel; production equipment used in the method provided by the invention is conventional equipment; the used solvent is a conventional solvent; a production condition is easy to implement; the method is simple to operate and suitable for industrialized production. The product can be used for a synthetic raw material for the paclitaxel and docetaxel and is applied to the field of medicines.

Owner:CHONGQING BEISHENG PHARMA TECH CO LTD

Method for producing 10-DAB (deacetylbaccatin) III at high yield by using taxus media

InactiveCN106397371AHigh yieldProduction conditions are easy to achieveOrganic chemistryOrganic solventDocetaxel

The invention relates to a method for producing 10-DAB (deacetylbaccatin) III at a high yield by using taxus media. The method for producing 10-DAB III at the high yield by using taxus media provided by the invention comprises the following steps of performing stirring extraction on the taxus media by using a solution; performing reduced pressure concentration to obtain an extract; adding organic solvents into the extract; performing stirring dissolution to obtain a dissolving solution; adding acid into the dissolving solution for acidizing an acidified solution; adding alkali into the acidified solution for neutralization; then, adding hydrazine hydrate, and performing stirring for hydrolyzation; adding reaction terminating agents until the solution is neutral to obtain hydrolysate; performing reduced pressure concentration on the hydrolysate to the thick state; then, performing extraction; concentrating the organic phase; then, performing re-crystallization purification to obtain a product. The content of the 10-DAB III in the 10-DAB III crude product prepared by the method is as high as 5.5 percent to 8.6 percent; the substances comprising 10-DAB III structures in the taxus media can be sufficiently used, so that the substances are changed from waste into valuable materials. The method is very suitable for industrial production. The 10-DAB III produced by the method can be used as synthesis raw materials of taxol and docetaxel to be applied in the field of medicine.

Owner:CHONGQING BEISHENG PHARMA TECH CO LTD

Solution pH adjustment method based on graphene quantum dots

The invention relates to the field of graphene quantum dots, in particular to a solution acidity-alkalinity regulating method based on a graphene quantum dot. The solution acidity-alkalinity regulating method comprises the following steps: a, preparing the graphene quantum dot; and b, regulating the solution acidity-alkalinity under illumination by the graphene quantum dot prepared in step a. Thegraphene quantum dot is prepared by adopting the following steps: 1, mechanically mixing a graphite powder lump with a molten salt catalyst; 2, performing preheating treatment on the mixture obtainedin step 1 and preserving heat; 3, directly heating the mixture after heat preservation in step 2 and preserving heat; 4, after cooling the mixture obtained in step 3 to the room temperature, performing water soaking treatment to obtain a suspension liquid; and 5, performing centrifugal filtration on the suspension liquid obtained in step 4 to obtain a graphene quantum dot product. The preparationmethod for the graphene quantum dot in a pesticide detection method is low in cost, high in degree of graphitization, and high in finished product quality, and therefore, the solution acidity-alkalinity can be effectively regulated, and the graphene quantum dot is suitable for large-scale production.

Owner:DONGGUAN UNIV OF TECH

Catalyst for electrochemical synthesis of ammonia based on graphene quantum dots and preparation method thereof

The invention relates to the field of graphene quantum dots, in particular to a preparation method of an ammonia electrochemical synthesis catalyst based on graphene quantum dots. The preparation method includes the steps of firstly, mechanically mixing graphite powder lumps and a fused-salt catalyst, wherein the fused-salt catalyst is the mixture of cesium carbonate fused salt and fused salt containing iron and molybdenum; secondly, subjecting the mixture obtained in the first step to thermal treatment and heat preservation; thirdly, directly heating the mixture obtained after the heat preservation in the second step, and performing heat preservation; fourthly, cooling the mixture obtained after the third step to room temperature, and soaking with water to obtain a suspension; fifthly, subjecting the suspension obtained in the fourth step to centrifugal filtering to obtain the ammonia electrochemical synthesis catalyst. The ammonia electrochemical synthesis catalyst is low in preparation cost, high in graphitization degree, good in quality, high in ammonia synthesis catalytic efficiency and applicable to large-scale production.

Owner:DONGGUAN UNIV OF TECH

Graphene quantum dots and preparation method thereof

ActiveCN109319766BHigh degree of graphitizationHigh purityMaterial nanotechnologyGraphenePtru catalystMolten salt

The invention relates to the field of graphene quantum dots, and particularly relates to a graphene quantum dot and a preparation method thereof. The preparation method of the graphene quantum dot comprises the following steps: (1), taking a graphite powder block to mechanically mix with a molten salt catalyst; (2), taking a mixed material in the step (1) to carry out preheating treatment and heatpreservation; (3), taking the mixed material subjected to the heat preservation in the step (2) to directly heat up and carry out the heat preservation; (4), cooling the mixed material in the step (3) to the room temperature, and then carrying out water immersion treatment to obtain suspension liquid; and (5), taking suspension liquid in the step (4), and carrying out centrifugal filtration to obtain a graphene quantum dot product. The preparation method of the graphene quantum dot, which is provided by the invention, has the advantages of low manufacturing cost, high graphitization degree, and good finished-product quality, and is applicable to large-scale production.

Owner:DONGGUAN UNIV OF TECH

A salt-free, dust-free, low-chlorine, environmentally friendly deicing agent and preparation method thereof

The invention discloses a salt-dust-free, low-chlorine, environment-friendly deicing agent and a preparation method thereof. The deicing agent prepared by the present invention is yellowish-brown granular, and its particle size is 0.3-0.6 cm. The chlorine content is more than 15% lower than that of common deicing agents, and its harm to the environment is also reduced by 30%-40%. It contains a low amount of chlorine. Chemicals, the damage and pollution to soil, plants, and groundwater resources are far lower than ordinary deicing agents, and there is no white salt stain on the surface after snow removal operations, effectively inhibiting the formation of salt dust and preventing secondary pollution.

Owner:金宝特兴(北京)科技开发有限公司

Industrial production method of semi-crystalline poly aryl ether nitrile

The invention relates to an industrial production method for semi-crystal poly(aromatic ether nitrile), which belongs to the field of polymer material. The method comprises the following steps: 2, 6-dichloro benzonitrile and hydroquinone are taken as raw materials; anhydrous potassium carbonate is taken as a catalyst; in the presence of a solvent and a dehydrating agent, the raw materials and thecatalyst react under atmospheric pressure to obtain the poly(aromatic ether nitrile) homopolymer with low molecular weight and regular chain segments; and then the molecular weight of polymer is increased through pressurization, so as to obtain the semi-crystal poly(aromatic ether nitrile) polymer with high molecular weight. Due to the increase of crystallinity and molecular weight, the mechanical properties and heat resistance of the semi-crystal poly(aromatic ether nitrile) polymer are obviously improved.

Owner:SICHUAN FEIYA NEW MATERIAL

Poly(aryl ether nitrile) composite material and its preparation method

The invention belongs to the field of polymeric nanocomposites and specifically relates to a poly(aryl ether nitrile) composite material and its preparation method. A first technical problem to be solved in the invention is to provide the poly(aryl ether nitrile) composite material with good mechanical strength and wear resistance. The poly(aryl ether nitrile) composite material is prepared by adding graphene microchips into poly(aryl ether nitrile) resin, wherein, the addition amount of the graphene microchips is no more than 10% of the weight of the poly(aryl ether nitrile) composite material. The poly(aryl ether nitrile) composite material prepared in the invention has excellent comprehensive performance: a tensile strength the material is 80 to 120 MPa, elongation at break is 8 to 25%, a flexural strength is 120 to 170 MPa, a flexural modulus is 3200 to 4400 MPa, an impact strength is 6 to14 J / m<2>, the coefficient of friction is 0.3 to 0.5, and resistance to a high temperature as high as 500 DEG C is obtained; the composite material not only has substantially improved mechanical properties and wear resistance but also reduces application cost of poly(aryl ether nitrile) products.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com