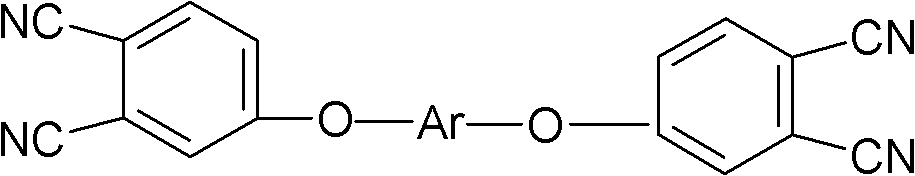

Poly (arylene ether nitrile) composite material and preparation method thereof

A technology of polyarylether nitrile and composite materials, which is applied in the field of polymer materials, can solve the problems of poor heat resistance, poor processing fluidity, and reduce the comprehensive performance of polyarylether nitrile, so as to improve mechanical strength, mechanical properties and heat resistance The effect of improving and reducing application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 polyarylether nitrile composite material

[0042] (1) Preparation of materials:

[0043] Polyarylene ether nitrile resin 50 kg

[0044] Fiberglass 40kg

[0045] Phthalocyanine prepolymer 5kg

[0046] Graphite 5 kg

[0047] (2) Production process:

[0048] 1. Raise the temperature of the twin-screw extruder to 330°C.

[0049] 2. Mix the polyarylether nitrile resin, graphite and phthalocyanine prepolymer uniformly on a high-speed mixer, and then put them into a twin-screw extruder to melt, blend, extrude and granulate to obtain polyarylether nitrile composite pellets. The shear section of the extruder is added.

[0050] 3. The polyarylether nitrile composite pellets are subjected to heat treatment at 200° C. for 24 hours after injection molding or compression molding to obtain a polyarylether nitrile composite material.

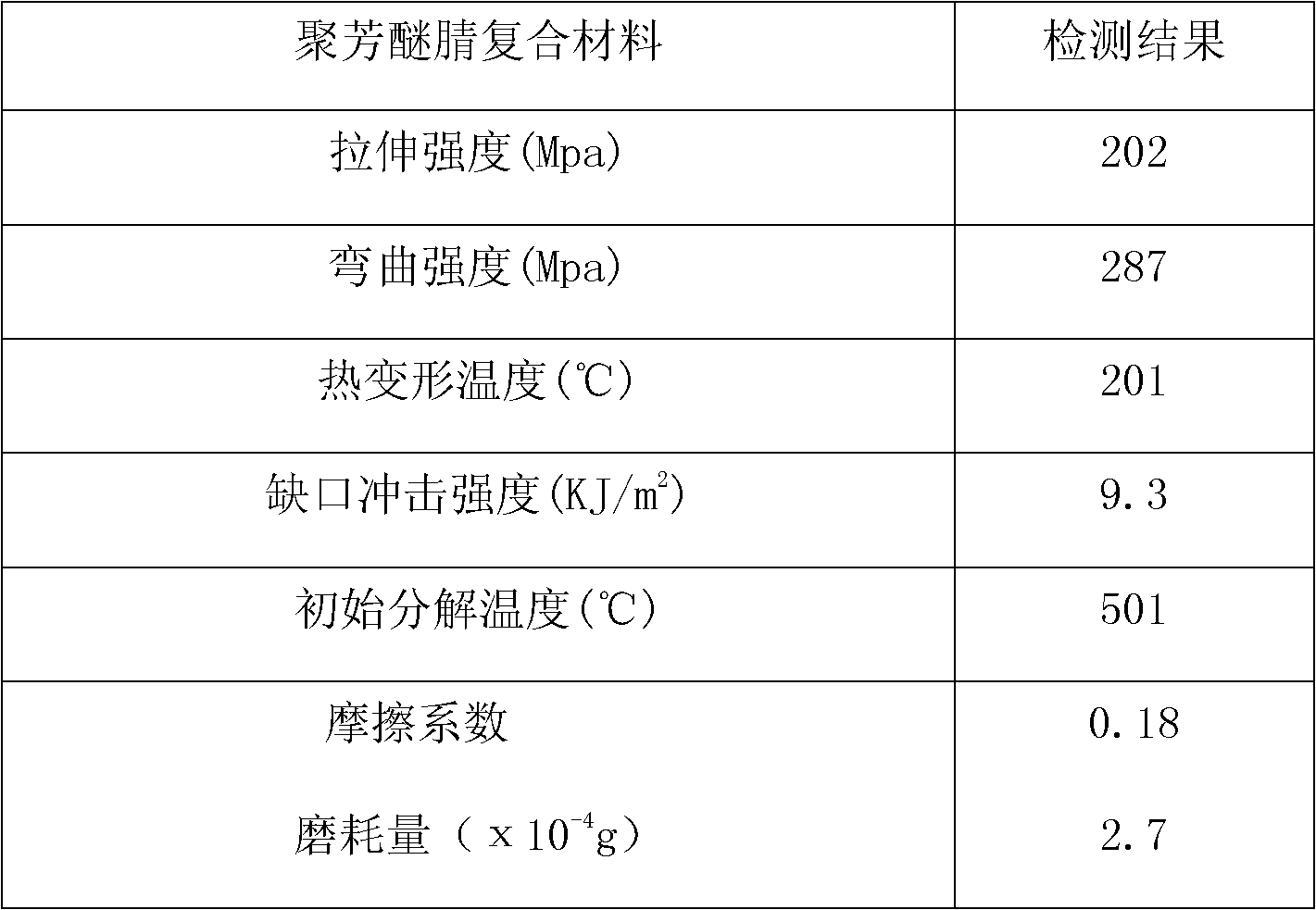

[0051] Product performance test see Table 1:

[0052] Table 1

[0053] polyarylether nitrile composite...

Embodiment 2

[0054] The preparation of embodiment 2 polyarylene ether nitrile composite material

[0055] (1) Preparation of materials:

[0056] Polyarylene ether nitrile resin 50 kg

[0057] Carbon Fiber 40kg

[0058] Phthalocyanine prepolymer 5 kg

[0059] Graphite 5 kg

[0060] (2) Production process:

[0061] 1. Raise the temperature of the twin-screw extruder to 330°C.

[0062] 2. Mix polyarylether nitrile resin, phthalocyanine prepolymer, and graphite on a high-speed mixer, and then put them into a twin-screw extruder to melt, blend, extrude and granulate to obtain polyarylether nitrile composite pellets. Carbon fibers are extruded in a twin-screw The extruded shear segment is added.

[0063] 3. The obtained polyarylether nitrile composite pellets are subjected to heat treatment at 200° C. for 24 hours after injection molding or compression molding to obtain a polyarylether nitrile composite material.

[0064] Product performance test table 4:

[0065] Table 4

[0066]

Embodiment 3

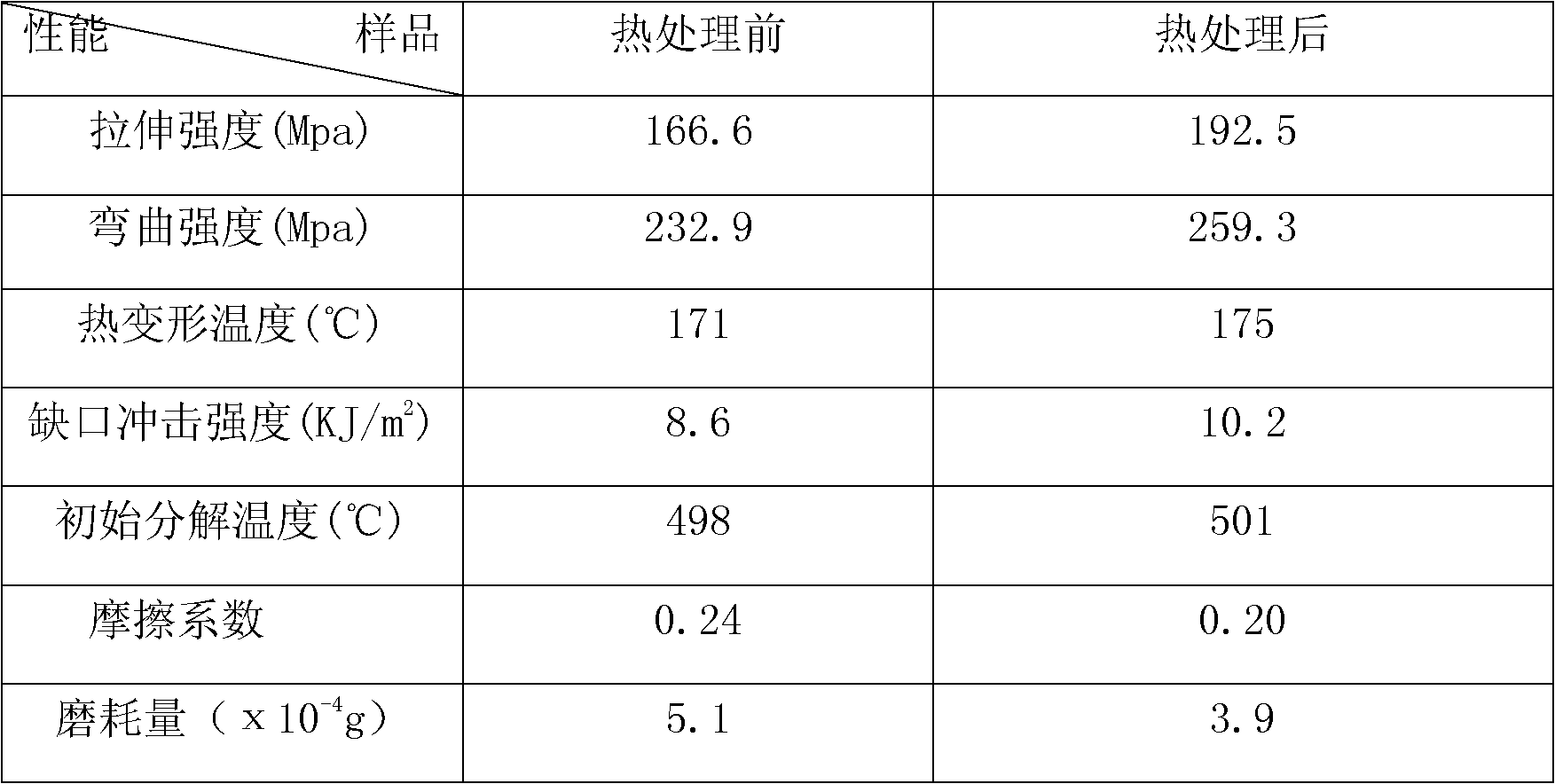

[0067] Performance comparison before and after heat treatment of embodiment 3 polyarylene ether nitrile composite material

[0068] (1) Preparation of materials:

[0069] Polyarylether nitrile 60 kg

[0070] Fiberglass 30kg

[0071] Phthalocyanine prepolymer 10 kg

[0072] (This embodiment is only used to compare the impact of heat treatment on performance, so no wear-resistant additives are added)

[0073] (2) Production process:

[0074] 1. Raise the temperature of the twin-screw extruder to 350°C.

[0075] 2. Mix polyarylether nitrile and phthalocyanine prepolymer on a high-speed mixer and put them into a twin-screw extruder for melt blending and extruding to granulate. Glass fiber is added in the shear section of the twin-screw extruder.

[0076] 3. The polyarylether nitrile composite pellets were injection molded or pressed as a sample before heat treatment. As a comparison, heat treatment was performed at 250°C for 24 hours to obtain a polyarylether nitrile composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com