Copolymerized resin of aromatic nitrile-based special resin containing benzoxazine ring and benzoxazine resin and its industrial preparation method

A technology of benzoxazine ring and benzoxazine, which is applied in the field of aromatic nitrile-based special resin and benzoxazine resin copolymer resin and its industrial preparation, can solve the problem of less consideration of industrial application and production of resin, processing cost and Efficiency affects the degree of industrialization and other issues, to achieve the effect of expanding the application field and application range, easy to realize production conditions, and various product forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

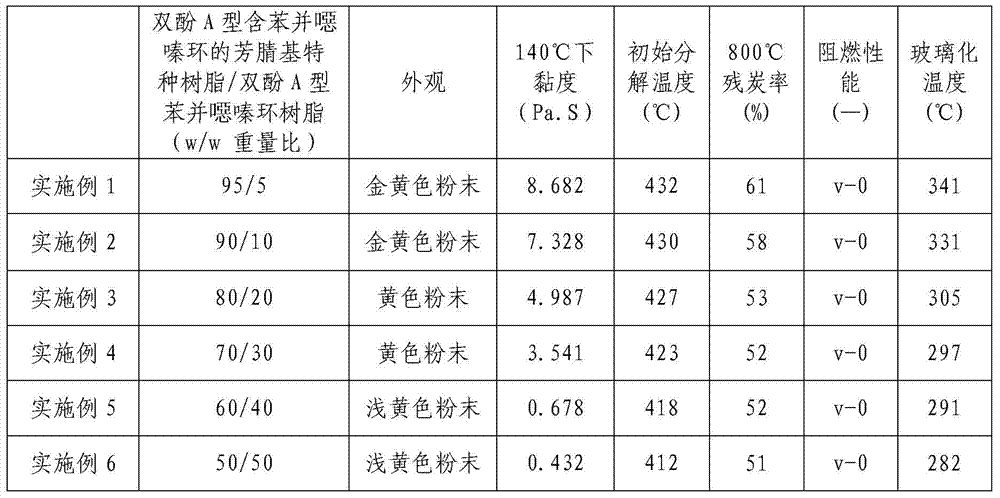

Embodiment 1

[0028] Example 1: Add 95kg bisphenol A aromatic nitrile-based special resin containing benzoxazine ring and 100kg N'N dimethylacetamide into the reaction kettle, stir and mix evenly, and perform ring-opening reaction in advance according to the following conditions: Temperature: 150°C; Time: 30min; Stirring speed: 300r / min; Pressure: normal pressure. Next, lower the temperature of the reactor, add 5kg of bisphenol A benzoxazine resin, and carry out the copolymerization reaction according to the following conditions: temperature: 140°C; time: 30min; stirring speed: 400r / min; pressure: normal pressure. Then, the N'N dimethylacetamide is distilled clean, discharged and pulverized to obtain a bisphenol A type aromatic nitrile-based special resin / bisphenol A type benzoxazine resin copolymer resin powder containing a benzoxazine ring.

Embodiment 2

[0029] Example 2: Add 90kg of bisphenol A-type aromatic nitrile-based special resin containing benzoxazine rings and 100kg of N'N dimethylacetamide into the reaction kettle, stir and mix evenly, and perform ring-opening reaction in advance according to the following conditions: Temperature: 160°C; Time: 60min; Stirring speed: 250r / min; Pressure: normal pressure. Next, lower the temperature of the reactor, add 10kg of bisphenol A benzoxazine resin, and carry out the copolymerization reaction according to the following conditions: temperature: 120°C; time: 30min; stirring speed: 250r / min; pressure: normal pressure. Then, the N'N dimethylacetamide is distilled clean, discharged and pulverized to obtain a bisphenol A type aromatic nitrile-based special resin / bisphenol A type benzoxazine resin copolymer resin powder containing a benzoxazine ring.

Embodiment 3

[0030] Example 3: Add 80kg of bisphenol A-type aromatic nitrile-based special resin containing benzoxazine ring and 150kg of N'N dimethylacetamide into the reaction kettle, stir and mix evenly, and perform ring-opening reaction in advance according to the following conditions : Temperature: 170°C; Time: 90min; Stirring speed: 200r / min; Pressure: normal pressure. Next, lower the temperature of the reactor, add a measured amount of bisphenol A benzoxazine resin, and carry out the copolymerization reaction according to the following conditions: temperature: 130°C; time: 120min; stirring speed: 350r / min; pressure: normal pressure. Then, the N'N dimethylacetamide is distilled clean, discharged and pulverized to obtain a bisphenol A type aromatic nitrile-based special resin / bisphenol A type benzoxazine resin copolymer resin powder containing a benzoxazine ring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com